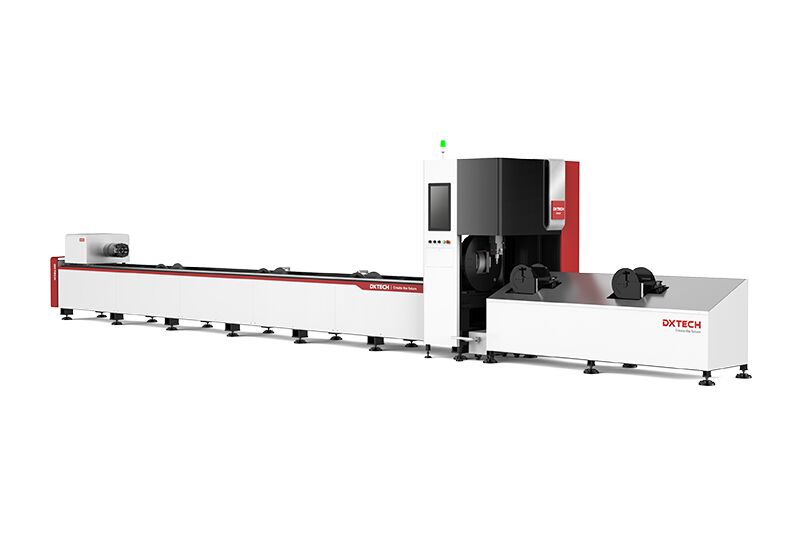

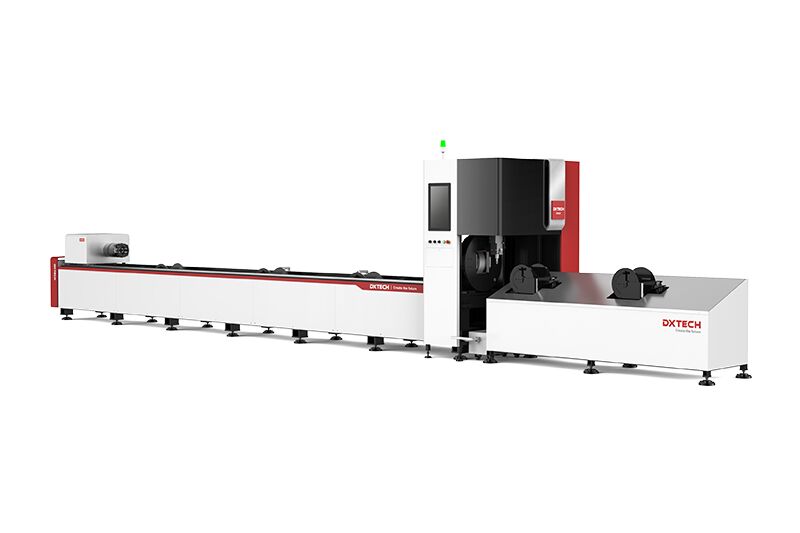

This professional metal tube laser cutting machine for stainless steel tube can process a variety of metal pipes and tubes, including round tubes, square tubes and special-shaped tubes or pipes. It can do hole cutting, beveling, grooving, vertical cutting, carving on metal tubes with high precision and efficiency. This metal tube laser cutter is widely used in automobile exhaust pipes, water pipes, oil pipes, fitness equipment, medical bed, bicycle frames, electric bicycle frames, baby carriages, kitchen storage racks, kitchenware, etc.

Video

Advantages

- With the excellent metal pipe clamping system, the machine can stably deliver metal pipes and manufacture high-quality and high-precision products. And itcan be equipped with a slag removal device for the inner wall of the pipe.

- The professional metal tube laser cutting machine for stainless steel tube uses a 3000w – 6000w Raycus/Max/IPG fiber laser source to accurately process metal with flat, smooth, burr-free cutting edges.

- Manufactured with aerospace aluminum gantry, this machine has high processing precision, good toughness and high processing speed.

- The machine can perform various 3D processing effects on metal pipes, such as hole cutting, arc cutting, carving, slotting, etc. And it can deal with various special-shaped metal tubes, such as rectangular tubes, oval tubes, square tubes, round tubes, triangular tubes, D-shaped tubes and hexagonal tubes.

- Reducing wheel loading station: strong load-bearing, low failure rate, suitable for ordinary round and square tubes, easy splicing, improve work efficiency

Components of metal tube laser cutting machine

Intelligent focusing laser head

- Autofocus: Autofocus range of -12 to +10 mm, focus accuracy of 0.05 mm, can reduce manual intervention.

- Multi-protection lenses: Adding collimation protection lenses to effectively protect the collimation lenses.

FSCUT3000S cutting software

- Supports a wide range of material cutting and high-precision cutting technology, adapting to the processing needs of a wide range of tubes and profiles.

- Capable of effective deviation compensation, reducing the precision requirements for raw materials and minimizing the generation of scrap.

- Supports automatic loading and cyclic processing, which greatly saves loading time and improves production efficiency.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.