Laser cutting machines are capable of processing a variety of metals, including highly reflective materials such as carbon steel, stainless steel, aluminum, copper, brass, titanium, nickel, and numerous alloys. These machines are widely used in industries like decoration, construction, infrastructure, microelectronics, advertising, kitchen appliances, automotive, and general equipment manufacturing.

Super Large Format Laser Cutting Machine Video

Advantages

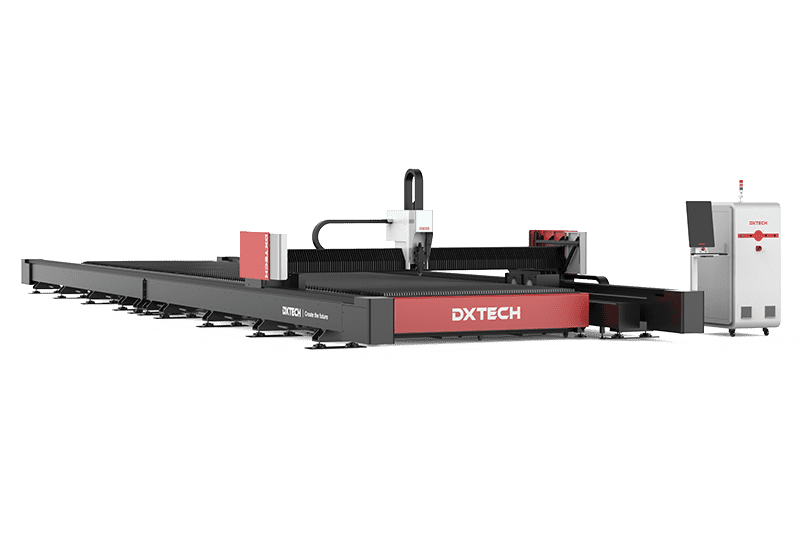

- Oversized processing format

The maximum processing format can reach 2500mm*12000mm, and the maximum thickness of the plate can be cut to 25mm. It can meet the requirements of large-format processing. Customized formats are supported. - Split frame support table

Reduce the load of the bed structure, decrease the impact of material rushing on the bed structure, ensure the accuracy of the machine, and improve the loading weight of the table. - Subdivided Fluid Domain Dusting

The smoke exhaust device automatically senses the laser cutting position to open precise smoke exhaust, closes the non-cutting area for smoke exhaust, fully enclosed smoke control, increases suction, and removes smoke to the greatest extent. - High Power, Precision Cutting

Featuring a robust 12,000W+ fiber laser, this machine effortlessly cuts through carbon steel, stainless steel, and aluminum alloy (0.5-50mm thickness) with unmatched speed and precision, significantly boosting productivity. - Modular Bed Design

The modular ground rail system ensures high rigidity and deformation resistance, maintaining millimeter-level accuracy (±0.05mm) even during prolonged operation. It eliminates vibration deviations, ensuring consistency for large-format cuts (2.5m×12m). - Split Frame Worktable

Reduces bed load and minimizes material impact, enhancing machine accuracy and increasing the worktable’s load capacity.

Features

The equipment meets the parts processing requirements of most industries, working accuracy is stable. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

DXTECH Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Components of Fiber Laser Cutting machine

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

We provide free proofing service. Welcome to consult.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.