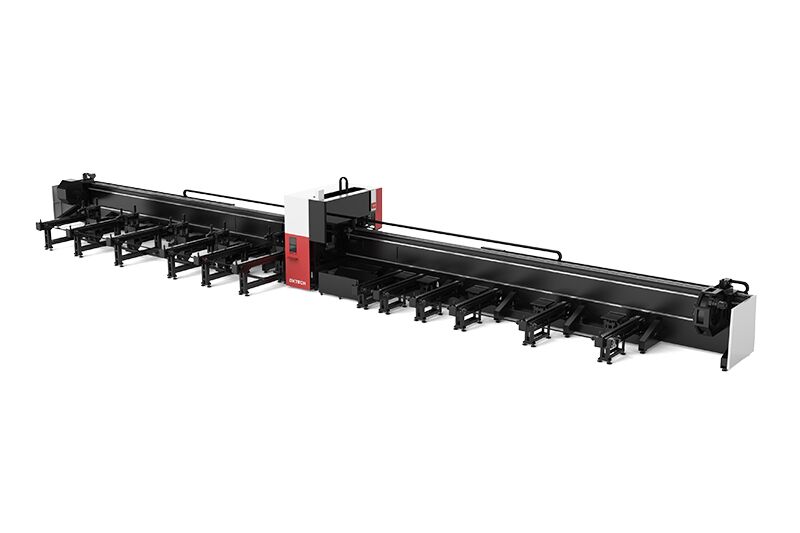

The Fully Automatic 20000W Wholesale 300mm Dia Round Pipe Laser Cutting Machine Fiber Laser Cutting Machine for Tube comes with a 4-chuck structure that features a four-jaw self-centering clamping function. It is equipped with an automatic tube bundle loading and finished product unloading system, which streamlines the production process. The three-dimensional laser cutting head it utilizes enables highly efficient cutting, significantly enhancing productivity. Moreover, it possesses a variety of excellent features such as section cutting control functions, allowing it to support high-speed laser cutting processing of round tubes, square tubes, profiled tubes, angle steel, I-beam, channel steel and other materials. This advanced machine combines multiple innovative elements to meet the diverse demands of modern manufacturing.

Video

Advantages

Unmatched Chuck Performance for Heavy-Duty Operations

Rock-Solid Stability and Superior Load-Bearing

Streamlined Loading and Unloading for Efficiency

Technical Parameters of metal tube laser cutting machine

| Model | TMTP12520 |

| Laser power | 20000W MAX |

| Positioning accuracy | ±0.05mm |

| Repositioning accuracy | ±0.03mm |

| Max. tube length | 12m |

| Max. tube weight | 1600kg |

| Tube materials | Stainless steel, carbon steel |

| Chucks | 3 pneumatic chucks |

| Cutting dimensions | Round: Φ120-Φ520mm Square: □120 – □520mm |

| Max. rotating speed of chuck | 40r/min |

| Max. speed of Z axis | 60m/min |

| Machine bed | Tube welded bed |

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.