▐ China Plate and Tube Fiber Laser Cutting Machine Applications

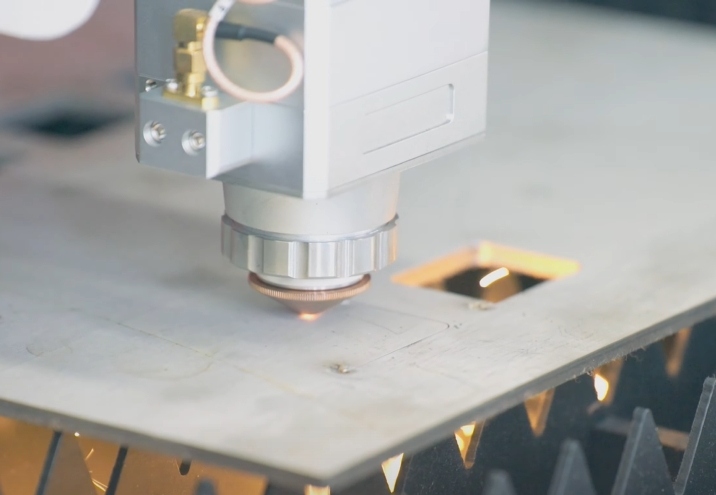

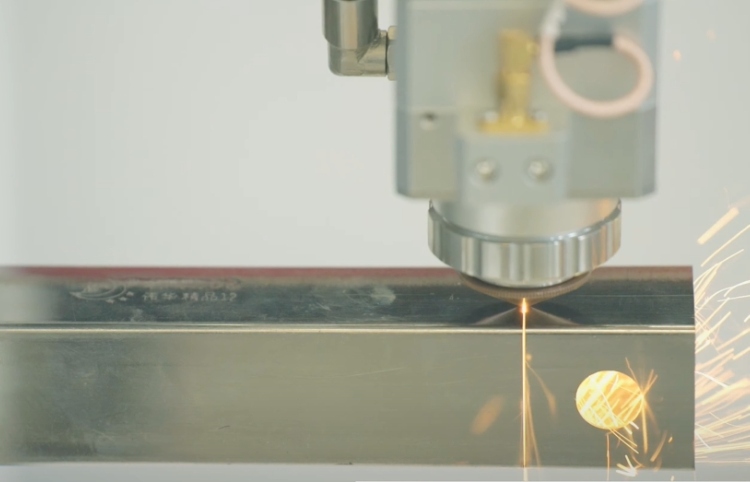

Laser cutting machines process metal materials—stainless steel, carbon steel, brass, and aluminum—and are widely used in industries like kitchen appliances, sheet metal enclosures, mechanical equipment, electrical devices, lighting hardware, advertising signage, automotive parts, display equipment, and various metal product manufacturing, including sheet metal cutting services.

▐ China Plate and Tube Fiber Laser Cutting Machine Features

✅ 1. Smart File Reading System

The intelligent cutting system directly supports .ai, .plt, .dxf, .lxd, and UG code formats for intuitive operation.

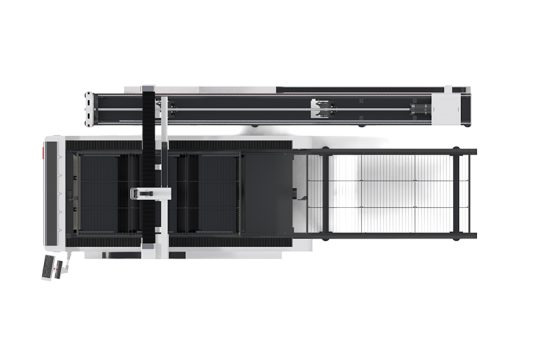

✅ 2. Dual-Function Space-Saving Machine

This dual-purpose machine processes most metal sheets, plates, and tubes, saving 50%+ workshop space while doubling productivity.

✅ 3. Auto-Chuck Pipe Cutting System

The pipe cutting unit features a fully automatic chuck for instant centering and clamping, with adjustable air pressure to maintain stable clamping force.

✅ 4. High-Temperature Tempered Gantry Frame

The machine body uses a 2nd-gen cast aluminum gantry frame—tempered at 600°C, furnace-cooled for 24 hours, precision-machined by imported gantry milling, and CO₂ shielded welded—ensuring 20+ years of deformation-free operation.

▐ China Plate and Tube Fiber Laser Cutting Machine Specifications

| Model | 1530FL3T Sheet Tube Laser Cutter |

| Working area (mm) | 1515x3030mm |

| Worktable bearing capacity | 600KG |

| Max. acceleration | 1.2G |

| Positioning accuracy | ±0.03mm |

| Repositioning accuracy | ±0.02mm |

| Pipe section shape | Round/square/rectangular |

| Max. length of pipe | 3m |

| Laser power | 1-3kW |

| Laser | MAX, Raycus, IPG |

| Max. running speed | 120m/min |

▐ DXTECH Services

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

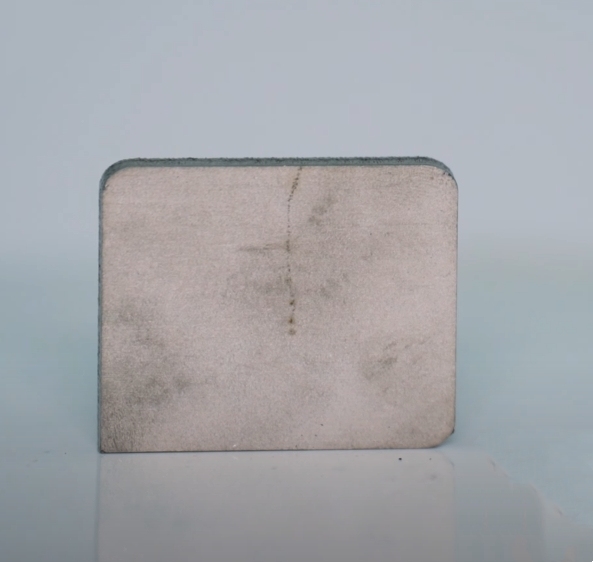

▐ China Plate and Tube Fiber Laser Cutting Machine Samples

We provide free proofing service. Welcome to consult.

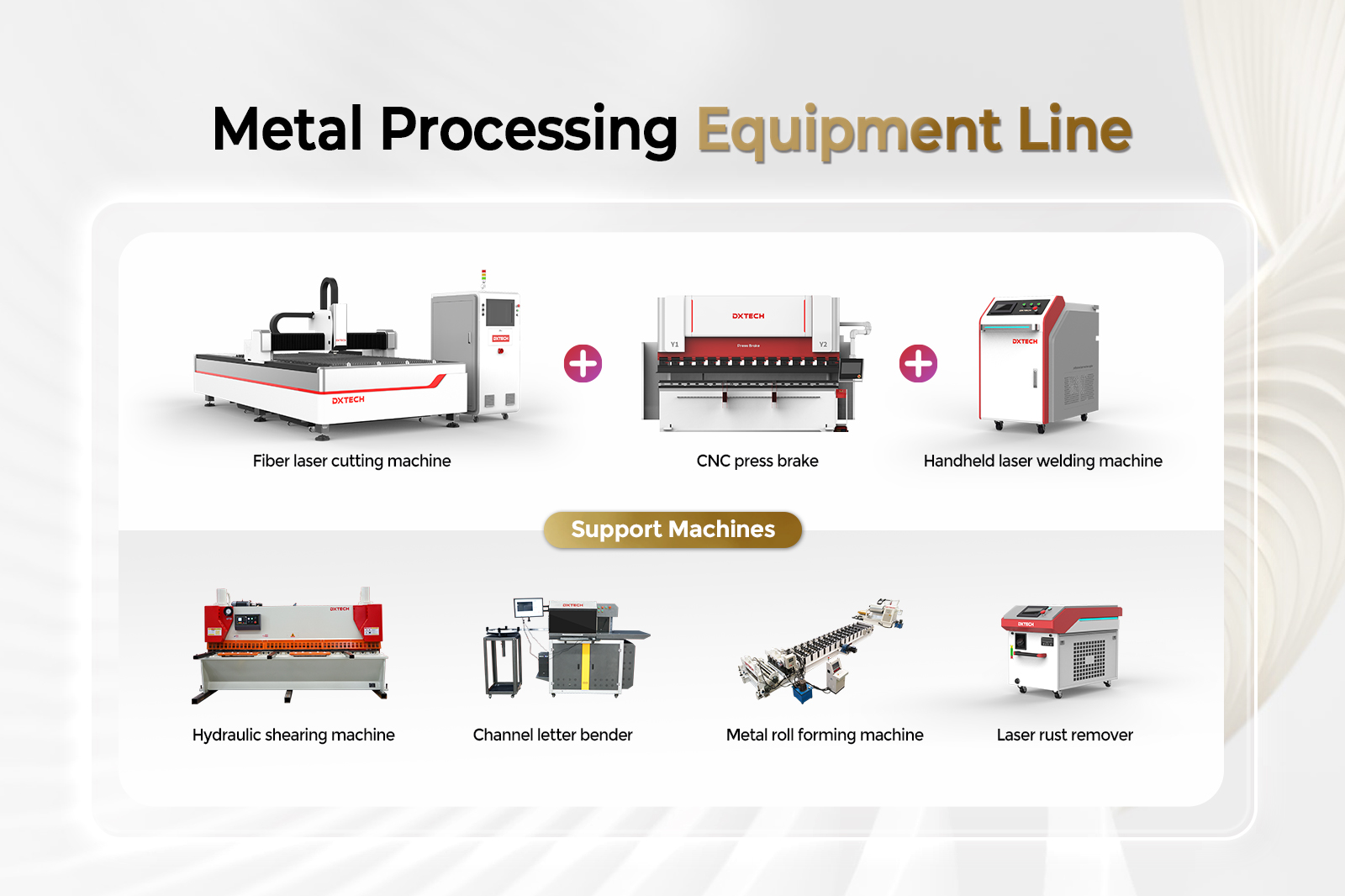

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.