┃Metal Rust Removal Oxide Painting Coating Removal Laser Cleaning Machine Applications

The fiber laser metal clean machine is designed for rapid laser cleaning of various metal materials, including carbon steel, silicon steel, stainless steel, aluminum alloys, titanium alloys, galvanized sheet, aluminum-zinc plate, and copper. It is widely applied in industries such as automotive repair, aerospace, and shipbuilding.

┃Metal Rust Removal Oxide Painting Coating Removal Laser Cleaning Machine Advantages

1. Substrate-Friendly Cleaning

Causes no or minimal damage to the substrate, preserving the dimensional accuracy of the cleaned object.

2. Ergonomic Handheld Design

Features a lightweight handheld cleaning head with ergonomic styling, ensuring ease of use and practicality.

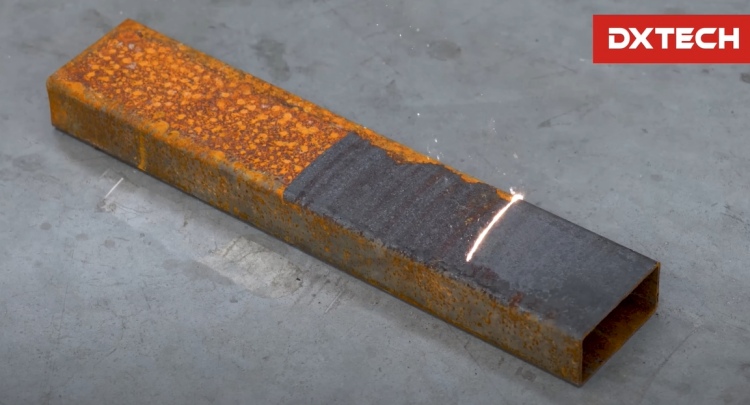

3. Versatile Surface Cleaning

Capable of removing rust spots, oxidized layers, dirt, and coatings across a wide range of applications.

4. Compact All-in-One Structure

Designed as a compact, one-piece unit for convenient shipping and space-saving operation.

▍Metal Rust Removal Oxide Painting Coating Removal Laser Cleaning Machine Technical Parameter

| Model | MCCW10/15/20/30 |

| Laser power | 1000-3000W |

| Laser source | Raycus, MAX |

| Laser welding gun | Chaoqiang SUP23T |

| Wavelength of laser | 1080nm |

| Cooling method | Water chiller |

| Cable length | 10m, optional: 20m |

| Functions | welding, rust removal, cutting, weld seam cleaning |

| Wire feeder | Automatic wire feeder |

| Cleaning width | 30-12mm, depending on the focal length of the focusing lens |

DXTECH Services

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

▍Laser Welding Machine Upgrade

DXTECH focuses on providing customized equipment upgrade solutions for your factory. If your factory is still using traditional equipment such as TIG/MIG welding machines with low welding efficiency and unsatisfactory welding quality, then DXTECH will be your ideal choice.

- Efficiency: 3-10 times higher

- Accuracy: minimum 0.1mm

- Welding power: 1-3KW

- Optical cable length: 10m/20m/30m

We can help you upgrade your TIG/MIG welding machine to a more efficient, more precise, and more energy-saving handheld laser welding machine. The welding quality and efficiency will be greatly improved, bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.