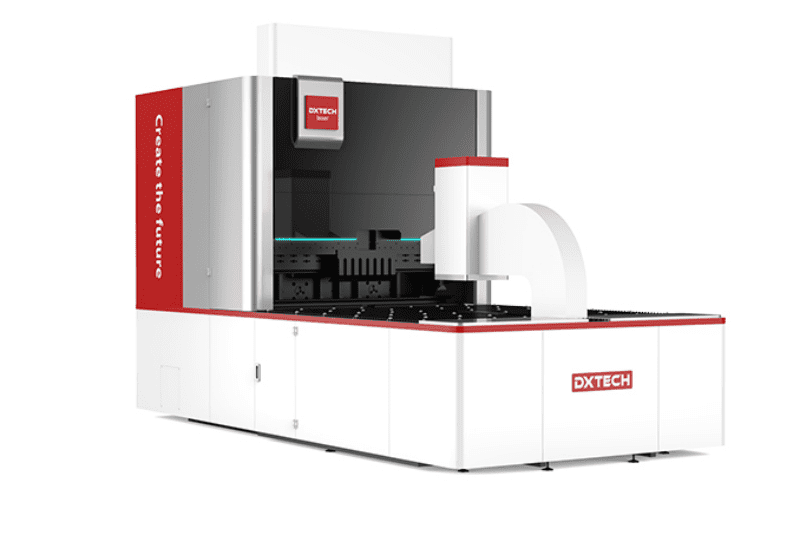

1.The main features of the machine of pressure arm type automatic plate bending center

1. Universal bending tool, available in various machine sizes and functions.

2. Good wear resistance and long service life. The whole machine can be bent more than 1 million times without frequent replacement of upper and lower bending tools.

3. High degree of automation and high production efficiency. It greatly saves manpower and production costs. The continuous bending speed is 3 times that of CNC bending machines, reaching 0.2s/time.

4. Using Star300-LGx intelligent CNC system, it can realize graphic visual programming and two-dimensional drawing process programming at the same time.

5. It can easily realize basic bending styles such as right angles, acute angles, and obtuse angles. It can also realize arc type, dead edge type, return type, closed type and other complex sheet metal bending requirements.

2.Main technical parameters of pressure arm type automatic plate bending center

| Model | DX-C2500 | |

| 1 | Bending Length | 2500mm |

| 2 | Plate Length | 2050mm |

| 3 | Plate Width | 1250mm |

| 4 | Bending Height | 175mm(Can be customized 320mm) |

| 5 | Min Forming Size(Four sides) | 300*200mm |

| 6 | Min Forming | 200mm |

| 7 | Min Radius | 1.2mm |

| 8 | Bending Speed | 0.5S/bend |

| 9 | Opening Height | 180mm |

| 10 | Angle | 0-360 ° |

| 11 | Material Thickness | Aluminum plate: 2.0mm Cold plate: 1.5mm Stainless steel: 1.2mm |

| 12 | Numerical System | Star300-LGx |

| 13 | Axis | Standard configuration 13 15/18 optional |

| 14 | Machine Dimension | Length 3700mm、Width 1800mm、Height 2500mm |

| 15 | Machine Weight | 10000kg |

3.Application industries and samples of pressure arm type automatic plate bending center

The pressure arm type automatic plate bending center

4.Working environment and conditions of use

This machine is suitable for any material preparation workshop, and its conditions are:

1) Power supply voltage: three-phase 380V AC-+10%

Frequency: 50HZ±1HZ

2) Operating environment temperature -20—+50℃

Humidity 20-85% (no condensation, no condensation)

Altitude<1000m

3) Protection level electrical control cabinet IP40

Control box IP45

This machine has no “three wastes” discharged, and the noise limit meets the requirements of JB9969-1999.

5.Installation, test, acceptance and after service

5.1.Seller should inform the buyer to inspect the machine in our factory after the machine is finished.

5.2.Seller should supply corresponding files and foundation drawings in 7 days after confirming the order.

5.3.If buyer needs the installation, test by seller, then the charges in China will be taken by seller. And charges out of China, such as tickets, and hotels, should be taken by the buyer.

Reviews

There are no reviews yet.