The shipbuilding industry primarily uses steel plates as raw materials, yet the metal processing requirements for these raw materials are becoming increasingly stringent. Currently, the shipbuilding industry primarily employs several methods for cutting ship plate components, including flame cutting, plasma cutting, and laser cutting. However, due to issues such as poor precision, significant thermal deformation, and high material waste rates associated with these traditional processing methods, they fail to meet the stringent requirements of the shipbuilding industry. Fiber laser cutting machines, with their high precision, low heat-affected zone, and compatibility with multiple materials, have become core equipment in modern shipbuilding. This article will provide a detailed overview of their applications in the processing of various critical components in shipbuilding.

▐ Ⅰ. Current Issues and Status in Shipbuilding Manufacturing

1. Stringent Requirements for Metal Processing in Shipbuilding

Extreme Environment Resistance Requirements:

Ships operate in harsh marine conditions, so hull components must withstand salt fog corrosion, high-impact waves, and extreme pressure—demanding exceptional material integrity and structural stability.

Strict Safety and Sealing Standards

Critical systems like piping must meet flawless sealing requirements to comply with SOLAS and IMO regulations, ensuring no leakage risks that could compromise vessel safety.

Limitations of Traditional Cutting Processes

Traditional methods (plasma, oxy-fuel cutting) struggle to meet shipbuilding needs:

- Accuracy: Tolerances often exceed ±1mm, leading to poor component fit.

- Thermal Deformation: Deformation reaches ≥0.5mm/m, weakening structural strength.

- Material Waste: Scrap rates as high as 15–20%, inflating production costs.

Core Processing Needs of Different Vessel Types

- Passenger ships (cruises, ferries): Require lightweight materials (high aluminum alloy content), precise interior components (tolerances of ±0.1mm), and fire-compliant stainless steel piping. Annual production of large vessels is approximately 1-5.

- Cargo ships (bulk carriers, container ships): Mainly use high-strength steel (AH36) for large-volume structural parts (keels and side keels with annual demand ≥1000 tons), emphasizing high efficiency and low waste.

- Engineering ships (dredgers, crane ships): Contain numerous irregular structures (such as dredging arms and crane frames), use diverse materials (high-strength steel, wear-resistant steel), and have high demand for small-batch customization.

- Fishing boats (trawlers, refrigerated vessels): Have relatively simple structures but require corrosion resistance (316L stainless steel piping), are cost-sensitive, and have short processing cycles (≤3 months per vessel).

- Port ships (tugs, pilot boats): Are mainly small and medium-sized, with small component sizes (keel length ≤20m), requiring a balance of strength and flexibility (e.g., quick disassembly and assembly of deck railings).

- Offshore development ships (drilling platform supply vessels): Must withstand extreme environments, with thick structural components (30-50mm thick plates) and high welding requirements (UT inspection pass rate ≥98%).

These varying needs highlight the limitations of traditional cutting methods in adapting to the diverse demands of shipbuilding.

▐ Ⅱ. Why Traditional Cutting Falls Short

1. Insufficient precision leading to assembly difficulties

Plasma cutting of T-section steel for side keels results in perpendicularity errors ≥1°, causing 5% of structural components to fail in normal welding.

2. Thermal deformation causing quality hazards

Flame cutting of 12mm thick steel plates results in a heat-affected zone (HAZ) of 3-5mm, leading to coarse material grains and a 10-15% reduction in strength, particularly risky for load-bearing components like stem posts.

3. Material waste and high costs

Traditional nesting methods result in scrap rates of 15-20%. A 10,000-ton ship wastes approximately 300 tons of steel, valued at over $180,000.

4. Low efficiency in processing complex components

Traditional cutting of irregular cabin partitions (checker plates) for engineering ships requires 3-4 processes, with a single piece taking ≥2 hours.

5. Poor sealing of piping systems after cutting

Grinding cutting of fire-fighting pipe bevels leaves burrs, resulting in a 5-8% leakage risk after welding, which fails to pass classification society inspections.

▐ Ⅲ. Core Technical Advantages of Fiber Laser Cutting for Shipbuilding

Unlike these traditional methods, fiber laser technology directly overcomes these hurdles:

1. High precision ensures structural strength

Cutting tolerances of ±0.05mm ensure tight fitting of bulb flats, T-section steel, and other structural components, enhancing the overall bending moment resistance of the hull and meeting classification society standards such as LR, DNV, ABS, CCS standards.

2. Low thermal deformation reduces secondary processing

Compared to flame cutting (thermal deformation of 0.5-1mm/m), laser cutting results in deformation <0.1mm/m, eliminating 80% of straightening time for critical load-bearing components like keels and side keels.

3. Efficient cutting of multiple materials

Capable of processing 6-50mm thick shipbuilding steel plates (AH36, DH36), stainless steel (316L for piping systems), and aluminum alloys (5083 for lightweight components), with cutting speeds of 1-3m/min for 12mm thick steel plates.

4. Nesting optimization reduces costs

Intelligent nesting software minimizes material waste, reducing scrap rates to below 5%. For example, a 5,000-ton cargo ship can save approximately $120,000 in steel costs.

▐ Ⅳ. 6 Critical Applications in Shipbuilding Manufacturing

1. Ship Keel Processing

Cutting Objects: Heavy-duty load-bearing profiles including bulb flats (12–20mm thick) and flat steel (10–30mm thick), which form the longitudinal backbone of the hull. These components bear 60–70% of the hull’s longitudinal bending force during navigation.

Technical Value: Fiber laser cutting achieves a straightness error of ≤0.5mm/m, far exceeding the ±1mm tolerance of plasma cutting. This precision ensures the keel maintains uniform stress distribution, enhancing the hull’s resistance to longitudinal bending by 30% (tested per CCS “Rules for the Classification of Steel Ships”). For bulk carriers, this reduces the risk of mid-ship hull cracking—a critical failure mode in heavy seas. A case study on a 50,000-ton bulk carrier showed laser-cut keels reduced structural maintenance costs by 25% over a 10-year service life.

2. Ship Side Keel Processing

Cutting Objects: T-section steel (flange thickness 8–16mm) and angle steel (10–20mm) that reinforce the main keel, distributing longitudinal loads to the hull sides. These components are critical for resisting lateral wave impacts.

Technical Value: Laser cutting ensures 45°/90° angle precision of ±0.1mm, eliminating the 1–2° deviation common in plasma cutting. This tight tolerance guarantees full weld penetration between the side keel, main keel, and bottom plate, reducing stress concentration by 40%. For fishing boats operating in rough coastal waters, this translates to a 15% lower risk of side keel detachment. Additionally, laser-cut T-sections require 80% less post-weld grinding compared to traditional methods.

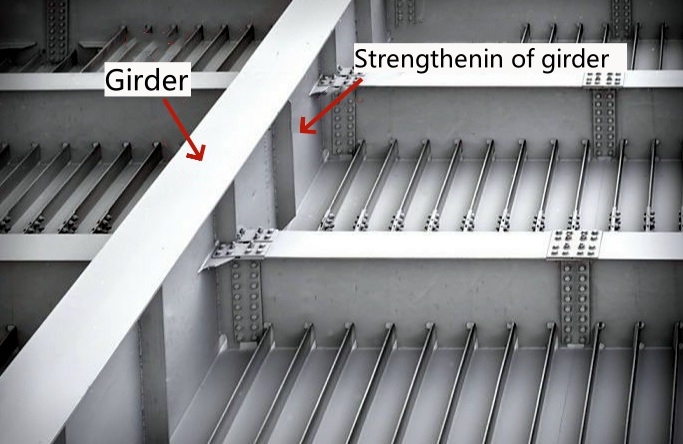

3. Longitudinal Girder Processing

Cutting Objects: Longitudinal structural profiles such as H-section steel and channel steel (10–25mm thick), which form a grid with transverse ribs to reinforce the hull sides and deck. These girders are vital for withstanding torsional forces in stormy conditions.

Technical Value: Fiber lasers cut complex 30°/60° bevels in a single pass, with surface roughness Ra ≤12.5μm—eliminating the uneven bevels and rework caused by flame cutting. This precision increases welding efficiency by 40%, as pre-fabricated bevels ensure consistent weld pool formation. For offshore supply vessels, which endure frequent torsional stress, laser-cut girders improve structural fatigue life by 20% (per DNV GL fatigue testing standards).

4. Stem and Stern Post Processing

Cutting Objects: Curved outer plates (15–30mm thick) that shape the ship’s bow and stern, inner reinforcing beams (10–20mm thick) for structural support, and flange fasteners (5–12mm thick) for connecting components. These parts directly impact hydrodynamic efficiency and crashworthiness.

Technical Value: 3D laser cutting systems process curved outer plates with a contour error ≤0.3mm, outperforming manual flame cutting (which typically has 5–8mm errors). This precision optimizes the stem’s hydrodynamics, reducing fuel consumption by 2–3% for large cargo ships. For passenger ferries, the smooth, accurate contours also enhance collision resistance—critical for meeting IMO SOLAS collision regulations. A 2023 study by a European shipyard found 3D laser-cut stern posts reduced water resistance by 4% in model tests.

5. System Piping Processing

Cutting Objects: Multi-material piping including bilge pipes (seamless steel, φ50–200mm, 5–10mm wall), fire-fighting pipes (316L stainless steel, φ32–100mm), and ventilation pipes (galvanized steel, 1–3mm). These systems must prevent leakage to avoid flooding, fire risks, or contamination.

Technical Value: Laser cutting achieves ±0.1mm dimensional precision and burr-free bevels, ensuring 100% welding tightness. This eliminates the 5–8% leakage rate of emery wheel – cut pipes, critical for passing IMO fire safety inspections. For refrigerated fishing vessels, laser-cut stainless steel pipes reduce corrosion-related maintenance by 30% compared to plasma-cut alternatives. Additionally, laser processing of ventilation pipes creates uniform holes with 0.05mm tolerance, optimizing airflow by 15% in cargo holds.

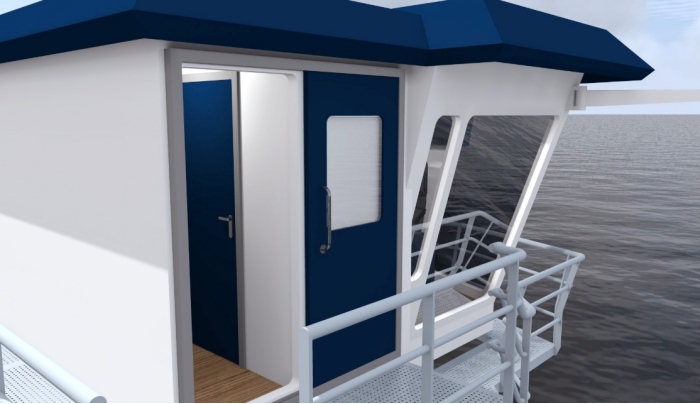

6. Cabin Structural Component Processing

Cutting Objects: Lightweight yet strong components such as passenger ship interior frames (6061 aluminum alloy, 3–8mm), cargo hold partitions (checker plates, 5–12mm), and deck railings (round steel, φ16–25mm). These parts balance functionality, safety, and weight.

Technical Value: High-precision cutting of aluminum alloy frames (tolerance ±0.05mm) ensures seamless assembly of passenger cabin interiors, reducing fitment issues by 90% compared to CNC milling. For cargo ships, laser-cut checker plate partitions (with 0.1mm precision holes) reduce weight by 10% while maintaining load capacity. Deck railings, cut with laser precision, feature smooth edges that lower injury risks by 60%—a key safety metric for offshore rig supply vessels. Overall, processing efficiency is 3x higher than traditional methods, with a single laser machine producing 50+ cabin components daily.

▐ Ⅴ. Future Trends: Integrated Automation Reshaping Shipbuilding

1. Automated production lines with integrated laser cutting machines

Fiber laser cutting machines are increasingly being integrated into automated production lines, such as automated sheet metal loading and unloading systems, AGV transport systems, and AI-based layout systems. These production lines can handle the entire process from raw material loading to finished product unloading. For example, in the shipbuilding industry, automated systems can load large steel plates, precisely cut them into the desired shapes using high-power fiber laser cutting machines (such as 10kW+ models), and then transfer the cut parts to the next assembly station. This reduces human error, increases production speed, and enables 24/7 continuous operation, significantly improving overall production efficiency.

2. Hybrid CNC-Laser Processing Center

The application of computer numerical control (CNC) combined with robotics and fiber laser cutting machines is becoming increasingly widespread. Robots can be programmed to perform tasks such as material loading and unloading, tool changes (if needed), and secondary processing. In complex ship component manufacturing scenarios, CNC-controlled fiber laser cutting machines can collaborate with robots. A robot picks up a steel plate, precisely positions it for the laser cutting machine to perform complex cuts, and then moves the cut components to the quality inspection area. This integration enhances production flexibility, enabling quick adjustments to production batches to meet different order requirements. Compared to non-automated systems, setup time can be reduced by 30% to 50%.

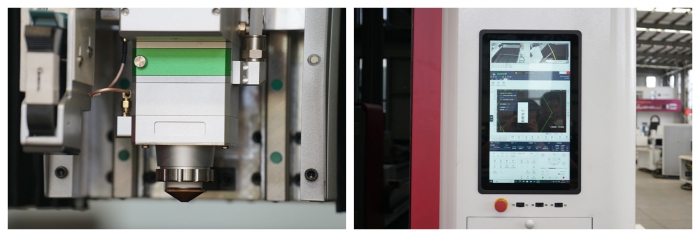

3. Smart Monitoring and Adaptive Systems

Fiber laser cutting machines are equipped with smart monitoring functions, enabling adaptive cutting and predictive layout capabilities. Sensors continuously monitor parameters such as laser power, beam quality, and material thickness. If deviations are detected, the system automatically adjusts cutting parameters. For example, if material thickness slightly varies during cutting, laser power and cutting speed can be automatically adjusted to maintain consistent cutting quality. This ensures high-quality output while reducing the need for continuous operator intervention, thereby achieving higher production efficiency.

4. Multi-Functional and Hybrid Processing

The trend toward multi-functional fiber laser cutting machines is becoming increasingly evident, such as in robotic 3D laser cutting ecosystems. The combination of a 6-axis robot and a fiber laser enables the processing of curved sheet metal. These machines not only cut but can also weld, drill, or mark on the same workpiece. In shipbuilding, a single machine can first cut the shape of a component, then weld it to other components, and finally mark it with an identification number. Hybrid processing reduces the need for multiple machines and repeated processing of workpieces, simplifying production processes and saving workshop time and space.

5. Cloud Connectivity and Data-Driven Operations

Fiber shipbuilding industry laser cutting machines will achieve cloud connectivity, supporting remote monitoring and control. Manufacturers can access data on equipment performance, production schedules, and maintenance requirements anytime, anywhere. Data analysis can further optimize cutting processes. For example, by analyzing historical cutting data, companies can identify patterns and trends to optimize cutting parameters, predict maintenance needs, and enhance overall equipment efficiency. This cloud-connected model also enables more convenient software updates and access to new features, ensuring the equipment remains at the forefront of technological innovation.

▐ Ⅵ. Shipyard Selection Guide: Matching Equipment Parameters by Vessel Type

1. Small fishing boats/port ships (≤1000 tons):

1000-3000W laser cutting machines, suitable for 6-15mm thick steel plates, with a 2000×4000mm worktable.

2. Cargo ships/engineering ships (1000-10000 tons):

4000-8000W laser cutting machines, supporting 15-30mm thick plates, equipped with automatic loading and unloading systems.

3. Large passenger ships/offshore development ships (≥10000 tons):

10000W+ laser cutting machines, compatible with 30-50mm thick high-strength steel, integrated with 3D cutting functions.

▐ Ⅶ. Conclusion

Fiber laser cutting machines address the key challenges in shipbuilding, including precision requirements, thermal deformation issues, material waste, and processing efficiency. Their six core applications, from keels to cabin components, significantly enhance the quality, efficiency, and cost-effectiveness of ship production.

As a professional manufacturer of laser cutting equipment, DXTECH offers tailored solutions for the shipbuilding industry. Our shipbuilding industry laser cutting machines, with their reliable performance, high precision, and diverse models, perfectly meet the processing needs of different types of ships. Whether for small fishing boats or large offshore vessels, DXTECH provides the ideal cutting solutions to drive the development of your shipbuilding business.