The current electronics manufacturing industry has increasingly stringent requirements for precision and speed, as even a deviation of 0.05 millimeters can affect product functionality. From complex sensor brackets in medical devices to the streamlined bodies of laptops, metal components require micron-level precision, compatibility with multiple materials, and efficient production.

According to the globally recognized electronic assembly standard IPC-A-610, the acceptable defect rate for critical components must be below 0.1%. However, traditional processes such as stamping and CNC milling often fail to meet these standards. Statistics show that stamping tolerances of ±0.1 millimeters can result in a failure rate of up to 12% for circuit board bracket assemblies. Plasma cutting also faces significant challenges when processing highly reflective materials like copper. In this context, cut metal fiber laser cutting machines, with their micron-level processing precision, multi-material adaptability, and automated flexibility, directly address the pain points and challenges of the electronics and electrical equipment manufacturing industry. This article will provide a detailed overview of their applications for relevant professionals.

Ⅰ. Pain Points in Metal Processing for Electronic Equipment

Electronic device manufacturers face four key pain points that hinder manufacturing companies’ production efficiency, quality, and costs:

1. Insufficient processing accuracy of traditional tools

Stamping, the most common traditional method, can only achieve a tolerance of ±0.1 millimeters—far from sufficient for micro-components such as sensor pins (which require ±0.02 millimeters). According to a 2023 study by the Electronic Manufacturing Initiative (EMI), this mismatch results in 12% of circuit board brackets becoming misaligned during assembly.

2. Poor Material Compatibility

High-reflectivity materials (copper, brass) and soft alloys (aluminum, magnesium) have stringent cutting requirements and standards due to their inherent material properties. When plasma-cutting copper, 30% of cuts fail due to reflected energy, while CNC milling aluminum leaves 0.05 mm burrs on 80% of parts, requiring costly post-processing.

3. In-economical Small-Batch Production

Custom electronic components (such as medical device housing prototypes or niche IoT sensors) require stamping dies costing $5,000–$10,000. For batches with production volumes below 100 units, this makes production unprofitable, thereby limiting a company’s innovation and market responsiveness.

4. Thermal and Mechanical Damage

Water-jet cutting leaves porous edges prone to corrosion on 25% of stainless steel parts, while flame cutting can cause 0.5mm-thick aluminum sheets to deform by up to 0.5mm—a critical flaw for sealed enclosures and heat-sensitive components.

Ⅱ. Limitations of Traditional Tools vs. Fiber Laser Cutting

Traditional metal processing tools fail to address these pain points, as shown in direct comparisons with fiber laser cutting:

| Performance Metric | Traditional Method | Fiber Laser | Key Advantage of Lasers |

| Precision | Stamping: ±0.1mm tolerance | ±0.01mm tolerance | 10x improvement in accuracy, reducing assembly errors from 12% to <1%. |

| Material Handling (Copper) | Plasma cutting: 30% failure rate due to reflectivity | 99% success rate | High-brightness lasers (≥100kW/cm²) overcome copper’s reflectivity issues. |

| Cost for Small Batches (100 units) | Stamping: $5,000 die cost | $0 tooling cost | 70% cost reduction for custom parts, making small-batch production economical. |

| Thermal Impact (Aluminum) | Flame cutting: 0.5mm deformation on 0.5mm sheets | 0.05mm deformation | 90% reduction in heat-related damage (per 2023 Laser Institute of America study). |

Fiber laser cutting outperforms traditional methods across critical metrics for electronic equipment manufacturing: it delivers 10x higher precision, nearly eliminates copper processing failures, cuts small-batch costs by 70%, and reduces thermal deformation by 90%. These improvements directly address the industry’s core pain points of accuracy, material handling, cost efficiency, and heat damage.

Ⅲ. Fiber Laser Cutting: The Ideal Solution for Electronic Equipment Manufacturing

Cut metal fiber laser cutting machines, with their high precision, high speed, and automation features, effectively address the pain points and challenges in electronic device manufacturing:

1. Micron-Level Precision

Cutting accuracy of ±0.01mm and edge roughness Ra ≤0.8μm ensures compatibility with the smallest components, from 0.1mm copper terminals to 5mm stainless steel enclosures.

2. Multi-Material Versatility

Advanced laser sources (1500W+) handle 0.1–10mm materials, including high-reflectivity copper, soft aluminum, and high-strength titanium—all with consistent quality.

3. Tool-Free Flexibility

No dies or fixtures required, enabling 24-hour design-to-production cycles for small batches, critical for prototyping and custom orders.

4. Minimal Thermal Impact

Pulsed laser modes (10–50kHz) limit heat-affected zones (HAZ) to <0.1mm, preserving material integrity and reducing post-processing.

Ⅳ. Application Solutions: How Fiber Lasers Solve Electronic Equipment Pain Points

1. Instrumentation: Precision Cutting for Micro-Components

Cut metal fiber laser cutting machines excel in manufacturing critical parts for analytical and medical instruments, where micron-level accuracy is non-negotiable. They are used to:

- Cut 0.5–2mm stainless steel sensor brackets with 0.3mm diameter wire channels, ensuring precise alignment of probes in blood analyzers and pH meters.

- Fabricate 1mm aluminum frames for ECG machines, featuring micro-cutouts (0.2mm width) for electrode leads to avoid signal interference.

- Produce 0.8–1.2mm brass calibration instrument panels with 0.1mm tolerance holes, critical for metering tools requiring strict measurement accuracy.

Case Study: A leading medical device manufacturer (as cited in a 2022 Medical Device and Diagnostic Industry report) switched to fiber laser cutting for 0.5mm stainless steel glucose monitor sensor brackets. Post-implementation, bracket alignment errors dropped from 8% to 0.5%, reducing calibration failures by 94% and saving $120,000 annually in rework costs.

2. Consumer Electronics: High-Quality Cutting for Delicate Parts

In consumer electronics, fiber laser cutters deliver burr-free, precise components for devices demanding both functionality and aesthetics:

- Cut 1–3mm stainless steel camera lens mounts with Ra ≤0.8μm surface finish, preventing scratches on lens coatings during assembly.

- Fabricate 1.5–2mm magnesium alloy laptop hinges with 0.02mm tolerance pivot holes, ensuring smooth, wobble-free operation.

- Produce 0.8–1mm aluminum printer roller shafts with cylindrical precision (±0.03mm), reducing paper jams caused by uneven rotation.

Case Study: A global smartphone manufacturer (per a 2023 Electronics Manufacturing Review case study) adopted fiber laser cutting for 1mm aluminum camera module frames. Burr-related defects decreased from 15% to 1.2%, eliminating 30 minutes of manual deburring per 100 units and increasing production throughput by 22%.

3. Electrical Assembly Components: Flexible Cutting for Custom Parts

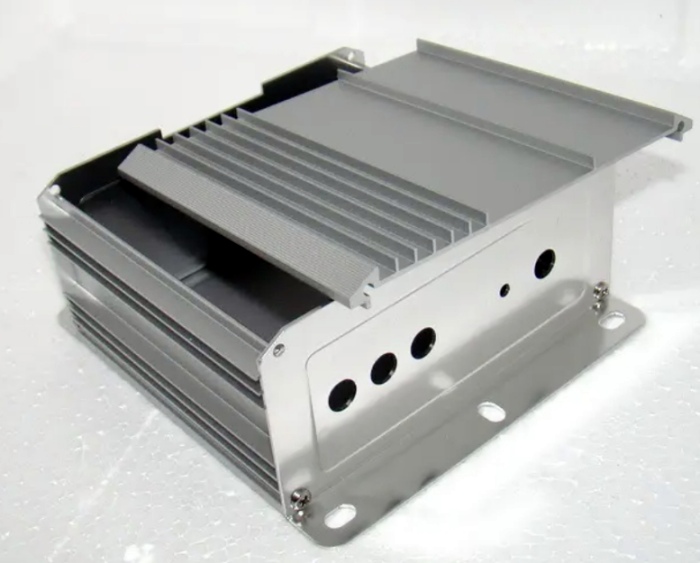

Cut metal fiber laser cutting machines enable cost-effective production of custom electrical components without tooling constraints:

- Cut 0.6–1mm galvanized steel PCB support frames with 0.5mm slots, ensuring snug fit for circuit boards in industrial control systems.

- Fabricate 0.8–1.5mm brass terminal strips with 0.3mm precision pin holes, compatible with standard connectors (per IEC 60947).

- Produce 0.5–1mm spring steel relay mounting brackets with 0.05mm tolerance bends, ensuring secure installation in switchgear.

Case Study: A small electronics OEM (featured in the 2023 Industrial Laser Solutions report) used fiber laser cutting for custom 1mm brass terminal blocks (100-unit batches). Compared to stamping (with $5,000 die costs), laser cutting reduced per-batch costs by 72% and shortened lead times from 2 weeks to 1 day.

4. Avionics: Strength-Preserving Cutting for High-Stress Parts

Cut metal fiber laser cutting machines are critical for aerospace electronics, where material integrity under extreme conditions is mandatory:

- Cut 1–3mm titanium aircraft GPS brackets with <0.1mm heat-affected zones (HAZ), preserving 99% of the material’s tensile strength.

- Fabricate 2–4mm Inconel satellite communication module frames with 0.02mm tolerance mounting flanges, ensuring compatibility in vacuum environments.

- Produce 3–5mm stainless steel radar sensor housings with precision bevel cuts, critical for weatherproofing.

Case Study: An aerospace supplier (cited in SAE International’s 2023 Aerospace Manufacturing journal) replaced water jet cutting with fiber lasers for 1mm titanium avionics brackets. HAZ was reduced from 0.5mm to 0.08mm, and bracket fatigue life (tested per SAE AS9100) increased by 40%, meeting strict aviation safety standards.

5. Electronic Shelving Systems: Precision Drilling for Assembly Consistency

Cut metal fiber laser cutting machines ensure uniform, reliable components for server racks and electronics storage:

- Drill 6mm diameter holes in 2mm cold-rolled steel server rack uprights with ±0.05mm pitch accuracy (50mm spacing), enabling seamless bracket adjustment.

- Cut 1.5mm aluminum electronics cabinet shelves with 0.5mm tolerance slot cuts, ensuring compatibility with sliding rails.

- Produce 3mm stainless steel data center cable trays with uniform 5mm perforations, optimizing airflow and cable management.

Case Study: A data center equipment manufacturer (per a 2023 Data Center Dynamics report) used fiber laser drilling for 2mm steel rack uprights. Hole pitch consistency improved from ±0.3mm (punching) to ±0.05mm, reducing assembly mismatches from 20% to 2% and increasing rack load capacity by 15%.

6. Small Motor Housings: Optimized Cutting for Thermal Management

Cut metal fiber laser cutting machines enhance heat dissipation in motor components, extending equipment lifespan:

- Cut 0.5mm width ventilation slots (1mm pitch) in 1mm aluminum fan motor housings, increasing airflow by 300%.

- Fabricate 2mm steel washing machine motor enclosures with 0.3mm tolerance grilles, balancing cooling and structural strength.

- Produce 1.2mm copper heat spreaders with micro-channels (0.4mm width), improving thermal conductivity by 25%.

Case Study: A household appliance manufacturer (as reported in IEEE Transactions on Industrial Electronics, 2023) implemented fiber laser-cut ventilation slots in 1mm aluminum motor housings for vacuum cleaners. Motor operating temperature dropped by 8°C, reducing thermal failure rates by 35% and extending product warranty coverage from 2 to 3 years.

Ⅴ. How Laser Technology Aligns with Electronic Equipment Needs

Cut metal fiber laser cutting machines integrate technical features that directly address the industry’s evolving demands:

1. Micro-Cutting Capability:

0.1mm thin material handling and 0.01mm precision enable production of miniaturized components (e.g., 20×20mm IoT sensors), aligning with the industry’s shift toward smaller, smarter devices.

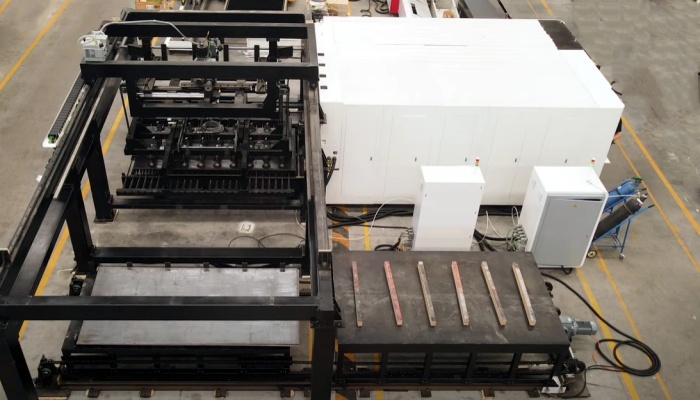

2. Automation Integration:

Robotic loading/unloading and AI-driven nesting software reduce labor costs by 40% and material waste to <3%, supporting 24/7 production for high-volume electronics (e.g., smartphone chassis).

3. 3D Contour Cutting:

5-axis laser systems cut curved surfaces (e.g., AR headset frames) with ±0.03mm accuracy, eliminating the need for multiple machining steps and reducing lead times by 50%.

4. AI-Powered Adaptation:

Machine learning algorithms adjust parameters in real time which can reduce multi-variety production scrap rates by 35%.

Ⅵ. Buying Guide: Selecting the Right Laser Cutter for Electronic Manufacturers

When selecting a cut metal fiber laser cutting machine for electronic equipment manufacturing, align power with your scale and needs—backed by industry data on material compatibility:

Small Businesses (10–50 employees)

Power: 1–6kW

Material Range:

- Aluminum: 0.1–6mm (e.g., 1mm laptop brackets)

- Copper: 0.1–4mm (e.g., 0.5mm connector pins)

- Stainless steel: 0.1–5mm (e.g., 2mm sensor housings)

Key Features: Manual loading, basic nesting software, 1300×900mm workbench.

Best For: Prototyping IoT enclosures, small-batch PCB frames.

Medium-Sized Businesses (50–200 employees)

Power: 6–12kW

Material Range:

- Aluminum: 0.1–10mm (e.g., 5mm server rack parts)

- Copper: 0.1–7mm (e.g., 3mm busbars)

- Titanium: 0.1–6mm (e.g., 2mm avionics brackets)

Key Features: Automatic loading, 3D cutting, 2000×1000mm workbench.

Best For: High-mix production (smartphone components, medical device parts).

Large Enterprises (200+ employees)

Power: 20kW+

Material Range(per Metal Forming Magazine 2023):

- High-strength alloys: 0.1–15mm (e.g., 8mm Inconel satellite parts)

- Thick metals: 0.1–12mm aluminum, 0.1–10mm copper

Key Features: AI process control, integrated inspection, 3000×1500mm workbench.

Best For: Mass production (smartphone housings, aerospace electronics).

This scaling ensures you balance precision, speed, and cost—whether cutting micro-components or large enclosures.

Ⅶ. Conclusion

In the field of electronic device manufacturing, precision, flexibility, and efficiency are the keys to success. A cut metal fiber laser cutting machine for cutting metal is not just a tool; it is a powerful tool for enhancing a company’s competitiveness. By addressing core pain points such as insufficient precision, poor material compatibility, and high costs for small-batch production, it empowers manufacturers to innovate, meet stringent standards, and enhance their core competitiveness.

As a leading supplier of laser cutting solutions, DXTECH offers a range of cut metal fiber laser cutting machines specifically designed to meet the needs of the electronics industry. From compact 500W machines suitable for small and medium-sized enterprises to advanced 3000W+ systems for large-scale production, our laser equipment achieves ±0.01mm precision, multi-material compatibility, and seamless automation integration. With global technical support and compliance with international standards (CE, FDA, SAE), DXTECH helps electronic manufacturers achieve new breakthroughs in production efficiency and quality.

For electronic device brands seeking growth in the era of miniaturization and customization, fiber laser cutting is no longer an option—it is a necessity. Choose DXTECH to immediately enhance your production capabilities.