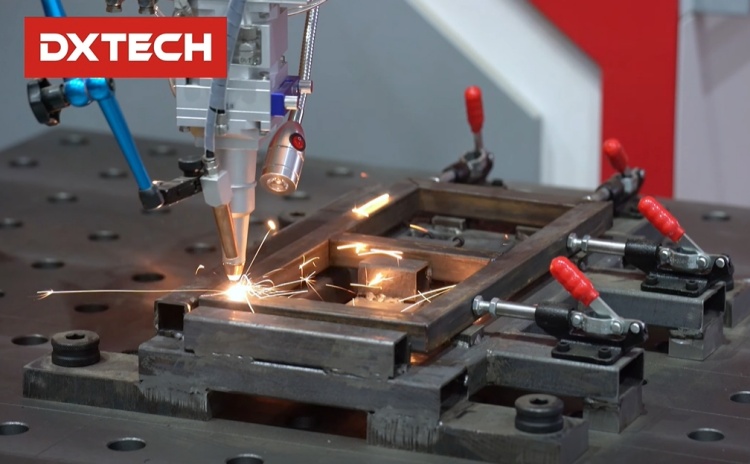

6 Axis Robotic Fiber Laser Welding Machine for Automotive Industry enable flexible welding in any direction, unrestricted by flat surfaces. Suitable for common metals like iron, stainless steel, galvanized alloys, and aluminum alloys, they allow parameter adjustment based on material and process to perform internal corner welding, external corner welding, butt welding, spot welding, fish scale welding, and other processes. Widely applied in automated welding of kitchenware, bathroom fixtures, door handles, precision parts, hardware, and other products.

6 Axis Robotic Fiber Laser Welding Machine Advantages

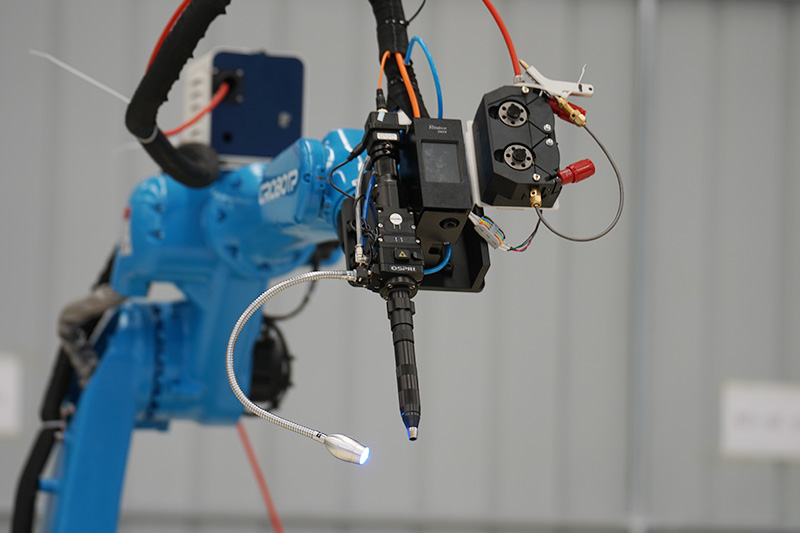

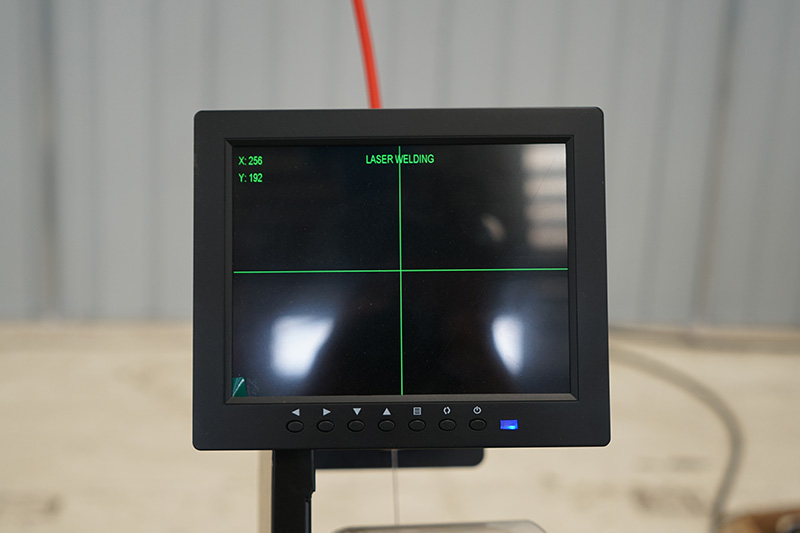

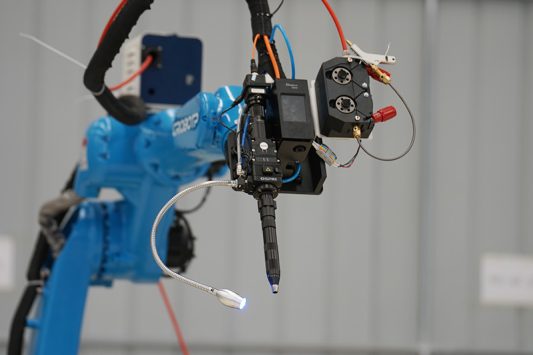

1. Advanced Oscillating Welding Head

The advanced oscillating welding head uses a unique wedge-shaped vibration technique to create wider weld seams, expanding laser welding applications and enabling processing of larger workpieces.

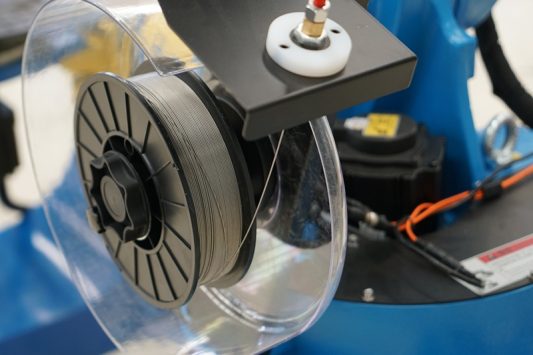

2. Continuous Robotic Welding with Precision

Robotic laser welding executes repetitive tasks 24/7 while maintaining welding precision and consistency. It requires no consumables, offering flexible manufacturing capabilities.

3. Dual/Single-Station Welding Efficiency

The robot supports dual-station or single-station welding, reducing fixture setup time and significantly boosting production efficiency.

4. Enhanced Circuit Safety System

Equipped with an independent emergency stop panel and safety relay circuit, it provides dual external emergency stop circuits for fault-safe reliability.

Components of 6 Axis Robotic Fiber Laser Welding Machine

6 Axis Robotic Arm

Designed for precision, these robotic arms enable flexible high-speed laser welding with sub-millimeter accuracy. They ensure optimal torch positioning, follow pre-programmed paths with repeatable precision, and adapt seamlessly to various welding tasks for consistent premium results.

Expert Laser Welding

Minimize deformation for aesthetic welds—no post-weld grinding required. Adjustable parameters ensure material/process compatibility, excelling in fillet (inner/outer), butt, spot, and fish scale welding. Ideal for iron, stainless steel, galvanized alloys, and aluminum.

Automated Laser Welding Systems

Compared to traditional techniques, automated laser welding systems deliver faster speeds, higher precision, and minimal material distortion—key advantages for modern manufacturing.

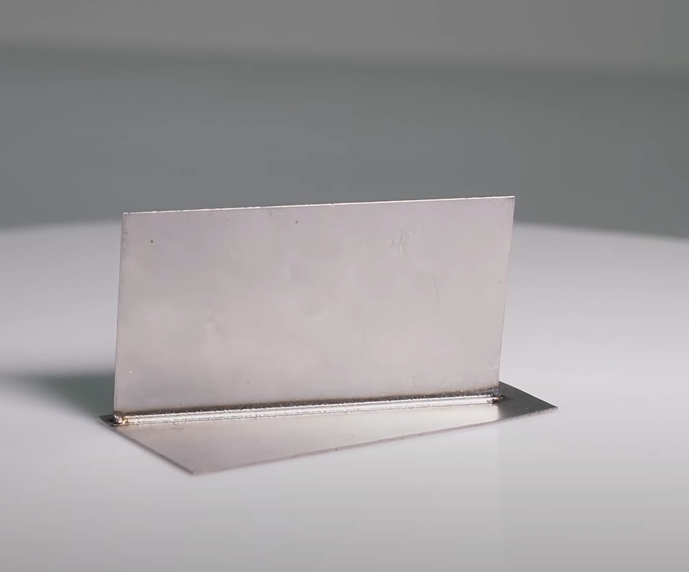

6 Axis Robotic Fiber Laser Welding Machine Samples

We provide free proofing service. Welcome to consult.

6 Axis Robotic Fiber Laser Welding Machine Specifications

| Model | RW18 6 Axis Robotic Fiber Laser Welding Machine for Automotive Industry |

| Laser power | 6000W |

| Laser source | Max |

| Laser wavelength | 1080±5nm |

| Robot | FANUC 6-axis laser welding robot |

| Laser head | WSX wobble laser welding head |

| Water chiller | Hanli |

| Voltage | 380V 50Hz 3PH |

DXTECH Services

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

DXTECH Quality Assurance

2 Years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Reviews

There are no reviews yet.