FPT 6000W Plate and Pipe Metal Laser Cutting Machine for Sale in Kenya

Recently, customers from Kenya visited DXTECH and ordered a FPT 6000W plate and pipe metal laser cutting machine with exchange platform. During this visit, the Kenyan customers were impressed by the excellent functions of our equipment and highly praised the professionalism and full-service of DXTECH staff. This recognition directly led to the successful cooperation between the two parties. DXTECH is proud to be a leader in laser technology and metal processing solutions in China, and we will do our best to meet the needs of our customers.

Customer Background and Needs

This customer from Kenya is engaged in the mechanical processing and manufacturing industry, providing tailor-made services for metal projects and structures. The customer currently uses metal sheet cutting equipment such as shearing machines and plasma cutting machines. In order to further improve production efficiency, the customer found DXTECH to seek possibilities.

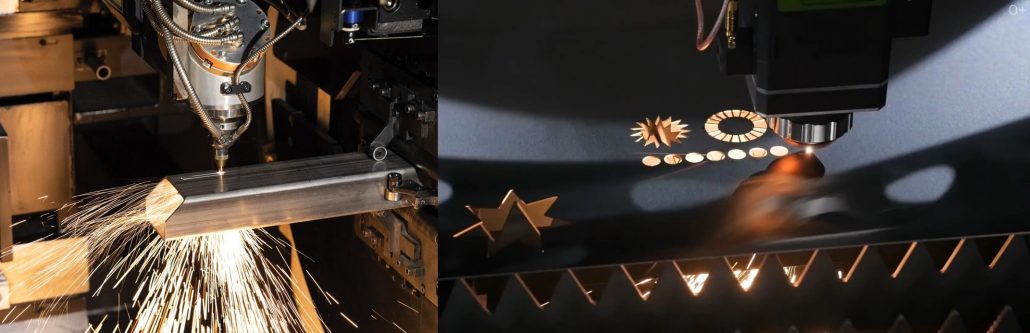

The purpose of their visit was to understand the advantages of fiber laser cutting machines and find possibilities to improve productivity. Accompanied by our sales and technical personnel, the customer visited the FPT 6000W plate and pipe metal laser cutting machine with exchange platform. Our team also provided customers with practical training on operating fiber laser machines.

Advantages of fiber laser cutting over plasma cutting machines

FPT 6000W Plate and Pipe Metal Laser Cutting Machine for Sale in Kenya

1. Precision and quality

The laser beam of fiber laser cutting is super high energy and concentrated, so the cutting accuracy is very high, even reaching micron-level errors. This is especially important when cutting complex shapes and processing ultra-fine parts. The smooth edges of laser cutting can save the trouble of subsequent grinding.

2. Adaptability to various materials and flexibility

Laser cutting is suitable for a variety of materials, such as metals (such as stainless steel, copper, aluminum alloys), plastics, wood and glass. As long as the power and cutting speed are adjusted, the laser cutting machine can easily handle materials of different thicknesses without changing tools at all, which is convenient and flexible.

3. Processing efficiency

Laser cutting is famous for its fast speed. It uses high-energy lasers to melt or evaporate materials instantly, and can handle complex cutting tasks in a short time, which is particularly suitable for large-scale production. On automated production lines, laser cutting machines can also achieve unmanned processing.

4. Production costs and savings

The initial investment of laser cutting equipment is a bit high, but the operating costs are relatively low. Because laser cutting does not require contact with the material, the tool wear is particularly small, and the cost of maintenance and tool replacement is also reduced. The high precision and high efficiency of laser cutting can also reduce material waste and production costs.

5. Environmental protection and safety

The laser cutting process does not produce a lot of waste gas, waste residue or dust, and has little impact on the environment. Compared with traditional cutting methods, laser cutting is less noisy and more environmentally friendly. In addition, laser cutting machines generally have safety measures to ensure safe operation.

Learn about DXTECH and conduct on-site inspection

DXTECH’s technical manager personally received the Kenyan customer and visited the factory’s metal processing equipment production line, including fiber laser cutting machines, bending machines, welding machines and other cutting-edge equipment. Among them, the FPT 6000W plate and pipe metal laser cutting machine with exchange platform that the customer was interested in was especially introduced. This dual-purpose laser cutting machine is designed for round and square metal pipe cutting and plate cutting. One machine has two uses, saving customers’ procurement costs and factory space. It uses a sturdy steel bed, a rack drive system, and a professional pipeline laser cutting CNC system to ensure that the CNC fiber laser cutting machine has good cutting accuracy and efficiency. And it is equipped with a switching table, which greatly improves the processing efficiency to meet customer needs.

We also provided sample cutting services to the Kenyan customer, and after witnessing the high performance of the DXTECH fiber laser machine, this customer from Kenya is now seriously considering upgrading their plasma cutting machine to take advantage of these advantages.

Finally, the dxtech sales manager gave detailed answers to every equipment-related question raised by the customer. At the same time, we also explained in detail the delivery process of the machine and the series of excellent after-sales services that will be enjoyed after the purchase, from equipment installation and commissioning to operation training, and then to subsequent technical support and maintenance.

Highly praised by the customer

FPT 6000W Plate and Pipe Metal Laser Cutting Machine for Sale in Kenya

After the factory tour, sales manager Allen interviewed the customer about his feelings about this trip to DXTECH. The customer highly praised the high performance of DXTECH machines and our customer service level. The customer said that the fiber laser cutting machine is more perfect than he imagined, the cutting speed and accuracy are better than the plasma cutting machine, and the operation is very simple, with many similarities with plasma cutting, and it is quick to learn.

DXTECH welcomes customers from all over the world to visit its state-of-the-art production facilities and explore its comprehensive metal manufacturing equipment and services. Whether you are looking for advanced laser cutting systems, high-precision press brakes, or versatile welding solutions, DXTECH is committed to helping you achieve new levels of efficiency and success in your metalworking operations.