CNC Hydraulic Press Brake Applications

The cnc hydraulic press brake is widely used in the metal fabrication industry, especially in sectors like architectural metalwork, automotive manufacturing, and aerospace manufacturing. It can be used for bending and processing all kinds of metal sheets, such as stainless steel, carbon steel and other metal sheets.

CNC Hydraulic Press Brake Videos

▍CNC Hydraulic Press Brake Advantages

1. Automated Precision Control

The slide strokes (Y1, Y2) and backstop positions (X, R, Z) are fully computer – automated. The backstop, featuring ball screws and linear guides, ensures high repeatability for accurate operations.

2. Reliable Hydraulic Protection and Adjustment

A relief valve safeguards against hydraulic overload, while a pressure switch allows for effortless adjustment of system pressure, ensuring stable performance and safety.

3. Swift and Easy Mold Changing

With the quick – change clamping device for the upper mold, tool changes can be carried out easily and rapidly, minimizing downtime and enhancing productivity.

4. Exceptional Stroke – Point Accuracy

It enables control at any point within the stroke, boasting a remarkable repeatability of up to +/-0.01 and parallelism of up to 0.02, guaranteeing precision in every bend.

CNC Hydraulic Press Brake Parameters

| MODEL | 40T/2500 | 63T/3200 | 125T/2500 | 125T/3200 |

| Nominal pressure | 400KN | 630KN | 1250KN | 1250KN |

| Working table length | 2500mm | 3200mm | 2500mm | 3200mm |

| throat depth | 260mm | 260mm | 400mm | 400mm |

| Slider stroke | 120mm | 120mm | 160mm | 160mm |

| Maximum opening height between work surface and slider | 320mm | 320mm | 460mm | 500mm |

| Maximum working pressure of hydraulic system | 25 | 25 | 25 | 25 |

| Motor power | 5.5kW | 5.5kW | 7.5kW | 7.5kW |

Laser Machine Upgrade

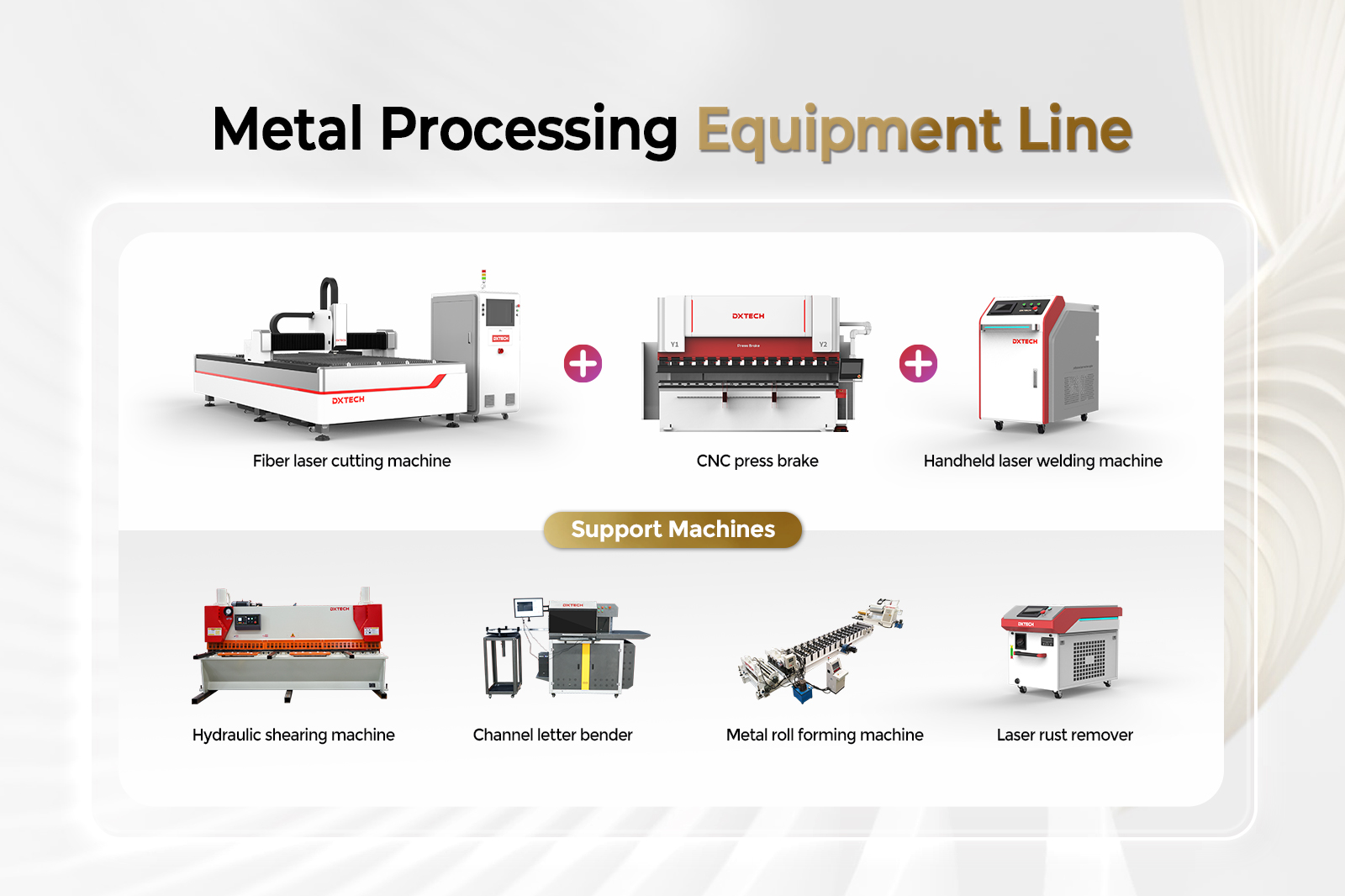

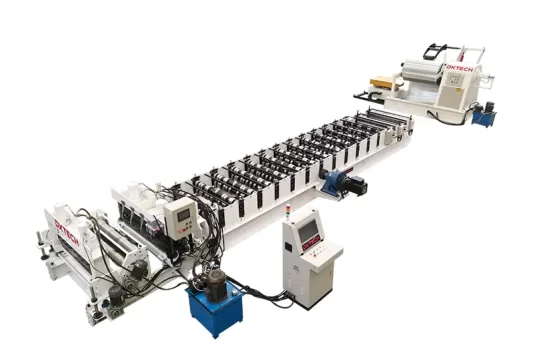

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Business in person. Currently, we have a workshop covering an area of 45,000㎡ in Jinan, and we are constructing a new factory with an area of 30,000㎡ in Taian, Shandong Province.

From the moment you receive your laser machine, our sales team and factory technicians will handle all your after-sales issues together.

We offer free online training and technical support. Additionally, we can visit your location to assist with installation, debugging, training, and usage matters.

DXTECH Quality Assurance

2 Years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Reviews

There are no reviews yet.