CNC Hydraulic Sheet Metal Press Brake Machine Applications

CNC Hydraulic Sheet Metal Press Brake Machine are vital in the following industries: the construction industry for shaping structural steel components, the automotive manufacturing industry for molding body panels, the appliance manufacturing industry for making refrigerator and washing machine components, the metal furniture manufacturing industry for bending metal frames, and the appliance enclosure manufacturing industry for making metal housings with precise angles.

CNC Hydraulic Sheet Metal Press Brake Machine Videos

▍CNC Hydraulic Sheet Metal Press Brake Machine

1. Safe and Reliable Hydraulic Performance

The hydraulic system features overload overflow protection, allowing the machine to operate continuously at rated load without leakage. This ensures stable and uninterrupted processing, safeguarding both the equipment and the workpieces.

2. Robust Construction for Precision

The machine frame is welded and then fully processed. High-quality imported seals are used in the cylinders. This combination guarantees high strength, rigidity, and precision, enabling accurate and consistent bending results.

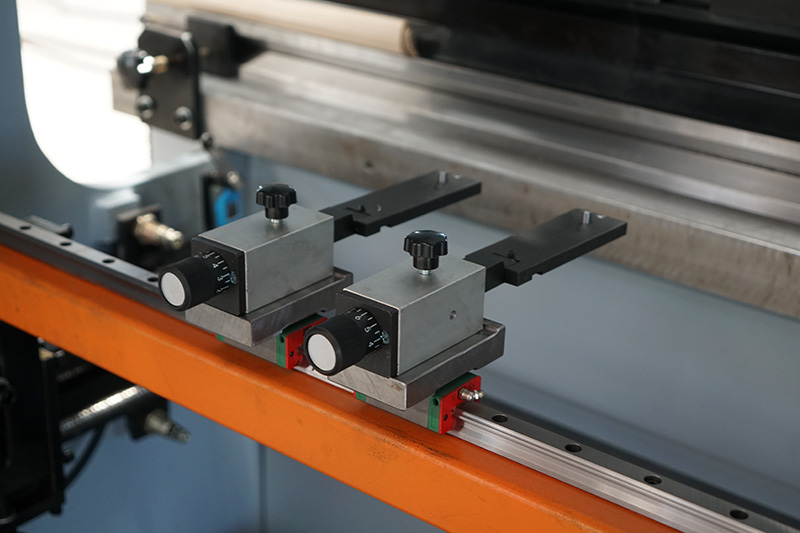

3. Swift Mold Changing

With a standard high-precision mold quick clip, mold changes are five times faster. This rapid changeover minimizes downtime, boosting overall productivity and making the machine more adaptable to different projects.

4. Enhanced Y-axis Precision

The Y-axis servo positioning function provides accurate control, significantly improving Y-axis precision. This not only ensures higher quality work but also greatly enhances work efficiency, making the bending process faster and more accurate.

CNC Hydraulic Sheet Metal Brake and Shearing Machine Technical Parameters

| MODEL | 40T/2500 | 63T/3200 | 125T/2500 | 125T/3200 |

| Nominal pressure | 400KN | 630KN | 1250KN | 1250KN |

| Working table length | 2500mm | 3200mm | 2500mm | 3200mm |

| throat depth | 260mm | 260mm | 400mm | 400mm |

| Slider stroke | 120mm | 120mm | 160mm | 160mm |

| Maximum opening height between work surface and slider | 320mm | 320mm | 460mm | 500mm |

| Maximum working pressure of hydraulic system | 25 | 25 | 25 | 25 |

| Motor power | 5.5kW | 5.5kW | 7.5kW | 7.5kW |

Laser Machine Upgrade

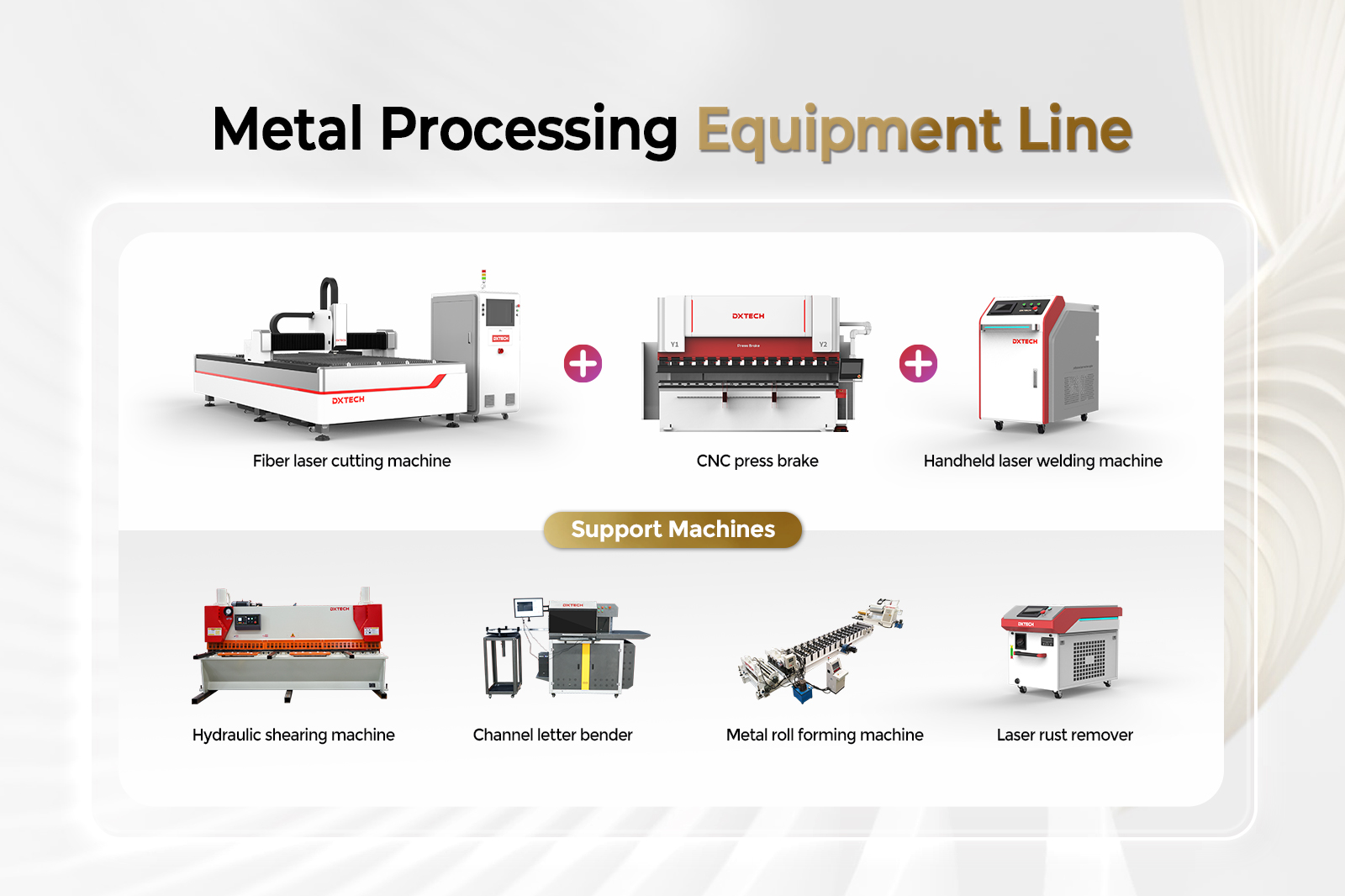

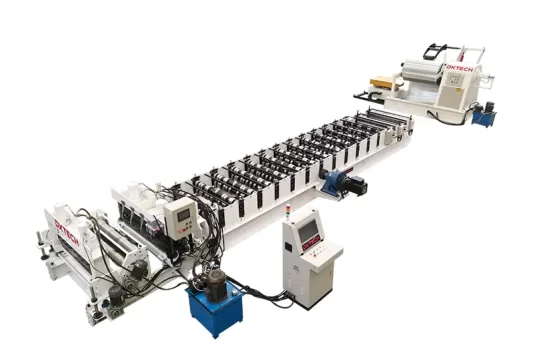

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Business in person. Currently, we have a workshop covering an area of 45,000㎡ in Jinan, and we are constructing a new factory with an area of 30,000㎡ in Taian, Shandong Province.

From the moment you receive your laser machine, our sales team and factory technicians will handle all your after-sales issues together.

We offer free online training and technical support. Additionally, we can visit your location to assist with installation, debugging, training, and usage matters.

Reviews

There are no reviews yet.