Today I will introduce to you the advantages of a high-power Fiber laser cutting machine compared to plasma.

Before 2015, there were long-term thickness limitations in the application of laser cutting. Traditionally, it is believed that flame cutting can cut the widest range of plate thicknesses. The speed advantage is obvious above 50mm, and it is suitable for processing thick and extra-thick plates with low precision requirements. Plasma cutting has obvious speed advantages in the 30-50mm range and is not suitable for processing. Especially thin plates (<2mm); laser cutting mostly uses kilowatt-class lasers, and the speed and accuracy advantages are obvious below 10mm.

However, with the upgrade of Fiber laser cutting machine technology, the current laser power has exceeded 100KW, and the ultimate cutting thickness has exceeded 500mm (carbon steel), and it has begun to develop towards thick plates and extra-thick plates.

As the power of fiber laser cutting machines increases, the cutting thickness and efficiency of the equipment increase at the same time, opening up the alternative to plasma cutting.

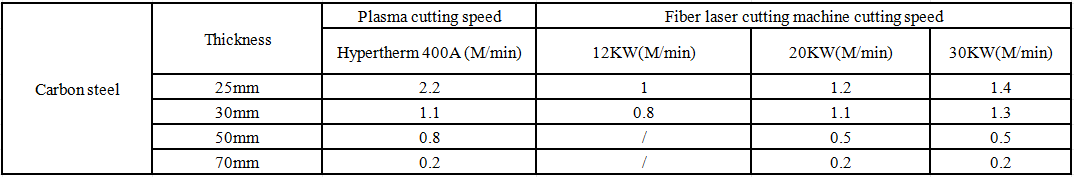

The 20KW laser cutting machine breaks through the optimal cutting thickness of carbon steel and stainless steel to 70mm respectively. Considering that steel plates are generally divided into thin plates (<4mm), medium plates (4-20mm), and thick plates (20-60mm) according to thickness , extra-thick plates (>60mm), Now high power fiber laser cutting machine can complete the cutting of medium-thin plates and most thick plates. The application scenarios of laser cutting equipment continue to extend to the field of medium-thick plates, reaching the thickness range of plasma cutting.

In addition to increasing the upper limit of the thickness of the cutting material, laser cutting has narrower slits and higher flatness than plasma cutting, and the cutting quality has been improved. On the other hand, high-power lasers have also continuously improved cutting efficiency. For example, when cutting 50mm carbon steel, the efficiency of a 30KW laser cutting machine can be increased by 88% compared to a 20KW cutting machine. High-power laser equipment has begun to replace plasma, and will accelerate the replacement of the plasma cutting market.

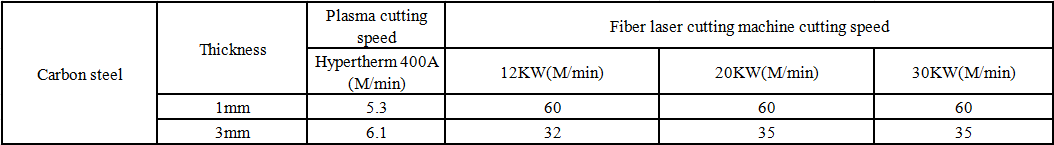

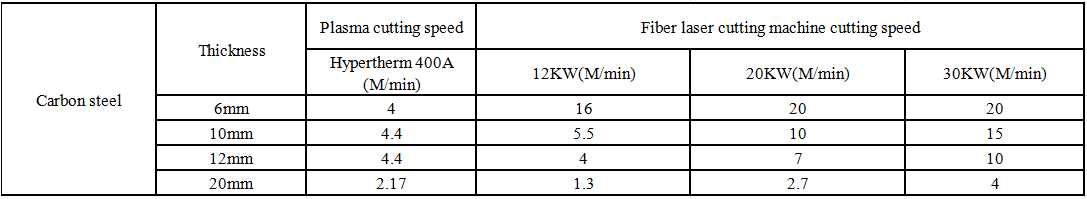

I can give you some data here for reference.

1)For thin plates (1-4mm),the cutting speed of fiber laser cutting machine is several times that of plasma. Its advantages are unquestionable.

In addition, because the Fiber laser cutting machine generates less heat when cutting thin plates. The board will not be thermally denatured or overcut. Therefore, the cutting accuracy is much higher than that of plasma.

2) In the cutting of medium plates (4-20mm), the cutting speed of the high-power Fiber laser cutting machine is also very obvious. Basically fiber cutting machines are 2-4 times more powerful than plasma.

In addition, another point is that high-power fiber cutting machines can use compressed air or (O2 + compressed air) to directly cut medium plates with a thickness of 1-20mm. So the operating cost is only electricity. Compared with plasma cutting per unit length, Fiber laser cutting machine has lower cutting cost, which will give customers a cost advantage in the same market.

3)When it comes to cutting thick plates (20-60mm) and extra-thick plates (>60mm), Plasma and fiber cutting speeds are basically the same(compared to 20KW/30KW).

However, the cutting gap of the optical fiber cutting machine is smaller, the precision is higher, and the surface is smoother.This is the cutting effect of fiber cutting machine cutting 50mm Carbon steel. You can refer to it.

DXTECH has been committed to the production and sales of laser equipment for 13 years. If you would like information about high-power fiber laser cutting machines, please contact us.