In modern manufacturing, the finish of a product is one of the important criteria for measuring its quality. Especially in the field of metal processing, the finish not only affects the aesthetics of the product but is also directly related to its service life and performance. Therefore, how to ensure the smoothness of metal processing products has become the focus of the manufacturing industry. As a high-precision and high-efficiency processing equipment, metal laser cutting machine has significant advantages in this regard. This article takes the DXTECH metal laser cutting machine as an example to discuss how to use the metal laser cutting machine to ensure the smoothness of the product.

Advantages of DXTECH metal laser cutting machine

DXTECH metal laser cutting machines are widely popular in the field of metal processing due to their advanced technology and excellent performance. Its advantages are mainly reflected in the following aspects:

1. High precision: DXTECH metal laser cutting machine adopts advanced laser technology and a high-precision control system, which can achieve micron-level cutting accuracy and ensure the dimensional accuracy and shape accuracy of processed products.

2. High efficiency: Laser cutting has the characteristics of fast speed and high efficiency. DXTECH metal laser cutting machine takes this advantage to the extreme, greatly improving production efficiency and reducing production costs.

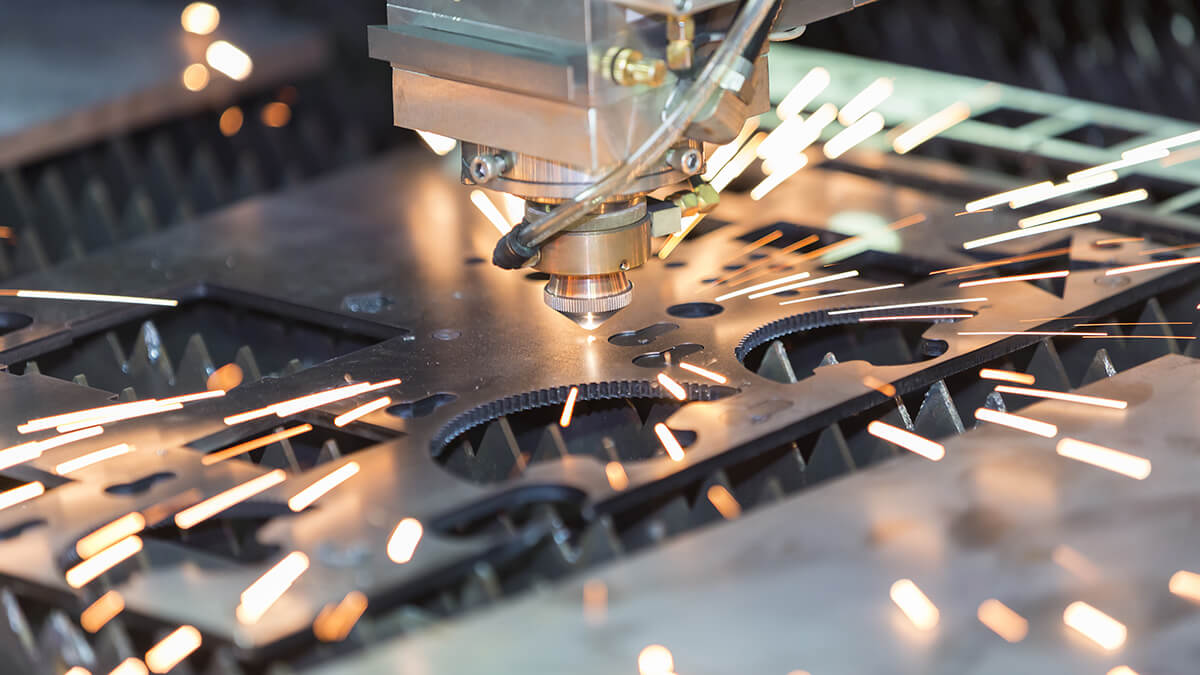

3. High smoothness: Laser cutting has the characteristics of small thermal impact and small thermal deformation. By optimizing cutting parameters and cutting gas selection, the DXTECH metal laser cutting machine can achieve high smoothness of the cutting surface, no burrs, and no slag hanging.

How to use the DXTECH metal laser cutting machine to ensure product smoothness?

1. Select the appropriate cutting gas:

In the metal laser cutting process, the choice of cutting gas has an important impact on the smoothness of the cutting surface. DXTECH metal laser cutting machine supports a variety of cutting gas choices. Users should choose the appropriate cutting gas according to the material type and processing requirements to improve the smoothness of the cutting surface.

2.Optimize cutting parameters:

The settings of cutting parameters also have a great impact on the smoothness of the cutting surface. Users should reasonably set cutting parameters, such as power, speed, frequency, etc., based on material thickness, hardness, and other characteristics, combined with the performance characteristics of DXTECH metal laser cutting machines, to achieve the best cutting effect.

3. Regular maintenance and upkeep:

Equipment maintenance and upkeep are equally important to ensure the smoothness of the cutting surface. Users should regularly maintain and maintain the DXTECH metal laser cutting machine, such as cleaning the cutting head, checking the wear of the guide rails, etc., to ensure that the equipment is in optimal working condition.

4. Reasonably adjust the tension of the working area:

During the cutting process, the tension in the working area also has a certain impact on the smoothness of the cutting surface. Users should reasonably adjust components such as the guide wheel and power supply block according to material characteristics and processing requirements to ensure constant tension in the working area to improve the smoothness of the cutting surface.

To sum up, the DXTECH metal laser cutting machine has broad application prospects in the field of metal processing with its advantages of high precision, high efficiency, and high finish. During use, users can further improve the finish of the product and meet higher quality requirements by selecting appropriate cutting gases, optimizing cutting parameters, regular maintenance and maintenance, and reasonably adjusting the tension of the working area.

If you are interested in the DXTECH metal laser cutting machine, please contact us!