Whether it is a laser novice or a professional manufacturer who has been in the CNC laser industry for many years, how to choose a suitable laser cutting machine for his current business development still troubles them. Indeed, it is not easy to choose a reliable metal fiber laser cutting machine with various functions, stable performance, and economical price. Therefore, in order to solve this demand of customers, DXTECH Laser sorted out the following selection suggestions. We hope it can give you who reading in front of the screen a little help.

Must meet your main processing needs

Find out whether the fiber laser cutting machine meets your specific cutting requirements. Make sure you want to cut metal sheets or metal tubes. Because there are three main categories of fiber laser cutters for sale: metal sheet laser cutting machines, metal tube laser cutting machines, and metal sheet & tube laser machines. Then notice what kind of materials you will process? How big is the format that can be completed? And how thick is the processed sheet that can be cut? In short, the equipment selection is affected by various aspects. The final decision should be made according to the different needs of the enterprise’s own processing requirements. The fiber laser cutter for metal can properly meet the company’s own processing needs and is the best choice.

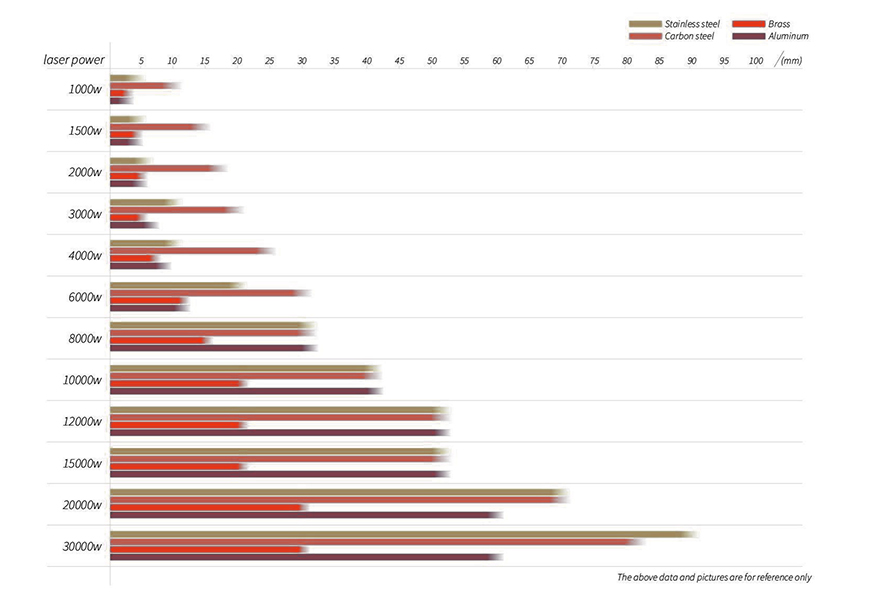

Suitable fiber laser power

When buying a metal fiber laser cutter, it is not that the higher the power, the better the working effect. Instead, we should choose the fiber laser power that is suitable for the metal type and diameter processed by our factory. Take the DXTECH Laser metal sheet laser cutting machine series as an example. It is divided into three types: 3KW-12KW high power, 15KW-20KW higher power, and 30KW ultra-high power. If you usually process stainless steel sheets within 2MM, a 1000W laser cutting machine is enough. But if you work on a 6-8MM stainless steel plate, choosing a 3000W laser cutting machine is cost-effective.

Having stable performance

Some manufacturers pay too much attention to the fiber laser cutting machine price, but ignore the configurations of the fiber laser equipment. The core configuration of the laser cutting machine mainly includes laser cutting head, laser generator, motor, control system, lens, and so on. These configurations determine the quality and performance of the fiber laser cutter machine, as well as the fiber laser cutter price. A laser processing equipment with stable performance is the basis for completing customer orders with quality and quantity. DXTECH fiber laser cutting machine has fast cutting speed, high processing efficiency, and good cutting effect. It can realize high-quality, high-precision, and high-efficiency cutting of three-dimensional workpieces without secondary processing. And it is especially suitable for edge trimming and hole cutting of automobile panels.

Reliable laser CNC supplier

Generally speaking, famous brands and large companies have complete R&D teams, professional technical support, and after-sales service system. Therefore, on the basis of purchasing products that meet the needs and have stable performance, manufacturers should try their best to choose suppliers with famous brands, high reputations, and high market share. In order to better improve customer experience, DXTECH Laser has established a complete market service system. Our sales & service network covers the global, which can quickly respond to various needs of customers all over the world. While the technical level and cutting efficiency are comparable to foreign leading laser equipment, our price is only about 70% of it. Plus, we offer shorter lead times and lower service costs.

For more laser industry knowledge, please visit https://dxtech.com/.