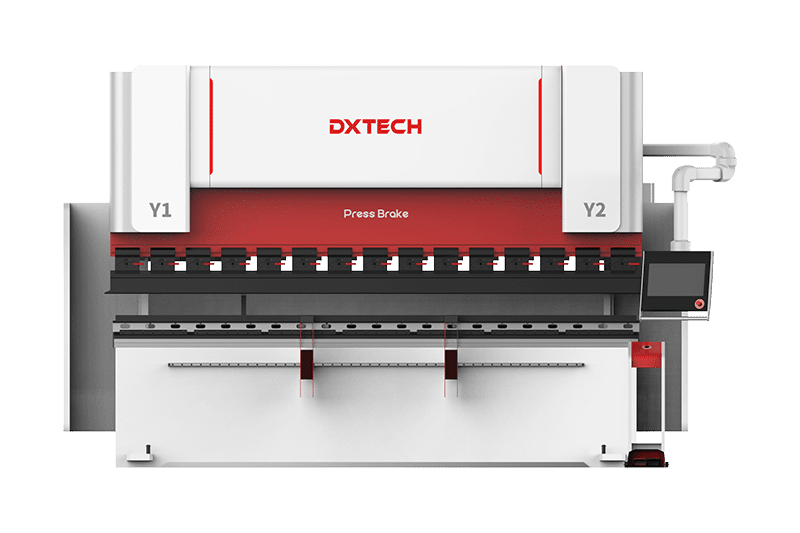

Hydraulic Press CNC Sheet Metal Bending Machine for Bending Dies Applications

The Hydraulic Press CNC Sheet Metal Bending Machine for Bending Dies finds extensive use across multiple industries. In the automotive sector, it’s crucial for crafting various body panels and structural components with high precision, ensuring a perfect fit and enhancing vehicle safety and aesthetics. The aerospace industry relies on this machine to shape lightweight yet strong metal parts for aircraft, where dimensional accuracy is non – negotiable. In the electronics field, it bends thin metal sheets to create enclosures for devices, protecting sensitive internal components. Additionally, in the furniture manufacturing industry, the machine is used to form metal frames and decorative elements, adding durability and style to furniture pieces.

Hydraulic Press CNC Sheet Metal Bending Machine for Bending Dies Videos

Features of High performance Hydraulic CNC Press Brake Metal Bending Machine for Sale in Kenya

1. Precise and Efficient Bending

The press brake machine makes use of advanced control tech. It enables high – precision bending with minimal errors. Its rapid response allows it to handle a large volume of bending tasks in a short span, significantly boosting production efficiency.

2. Reliable and Smart System

This press brake is powered by a real – time Windows embedded OS. It supports instant shutdown. The built – in PLC function streamlines circuit design, enhancing overall reliability.

3. User – Friendly Operation

Equipped with a user – friendly human – machine interface, the press brake machine is a breeze to operate. No complex professional training is needed, making it accessible to a wide range of users.

4. High – Precision Slider Performance

The slider position feedback boasts high precision, ensuring accurate and smooth operation. It offers excellent synchronization, leading to high – level bending precision and outstanding slider repositioning accuracy.

Main technical parameters

| Model | DX-PB-125T/2500 |

| Control System | DE-15 |

| No. of Axes | 4+1 (Y1, Y2, X, R+V) |

| Nominal Force | 1250kN |

| Bending Length | 2500mm |

| Distance between Columns | 2080mm |

| Throat Depth | 400mm |

| Slider Stroke | 200mm |

| Main Motor Power | 7.5kW |

| Voltage | 380V 50Hz 3PH |

| Operation Environment | Temperature -20 ~ +50℃ Humidity 20~85% |

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.