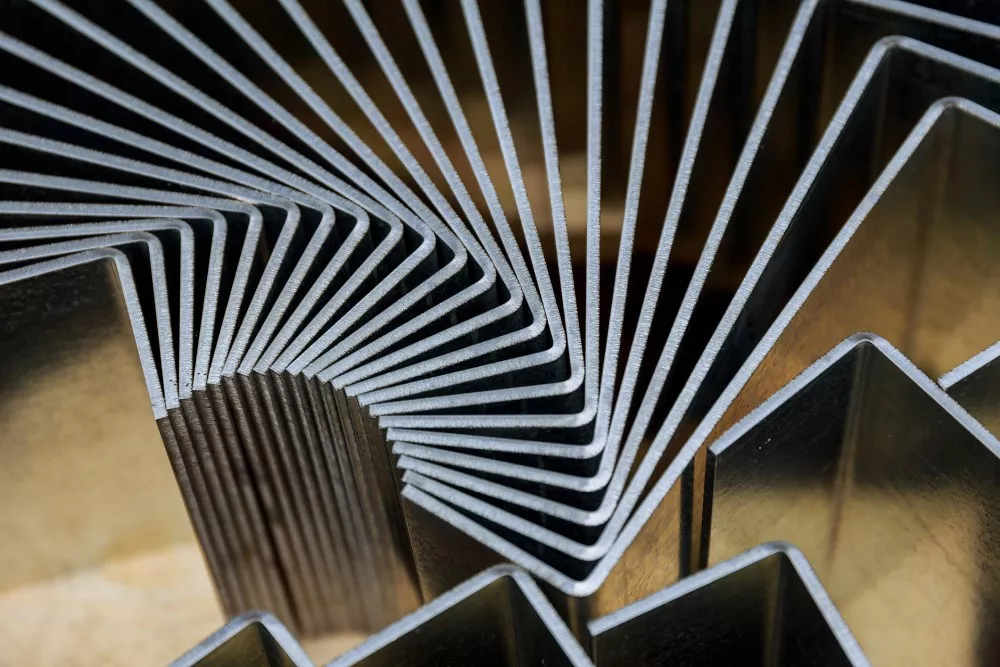

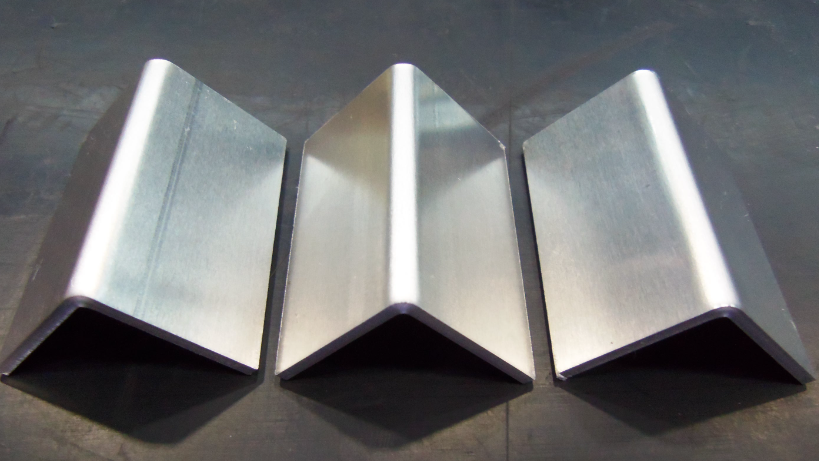

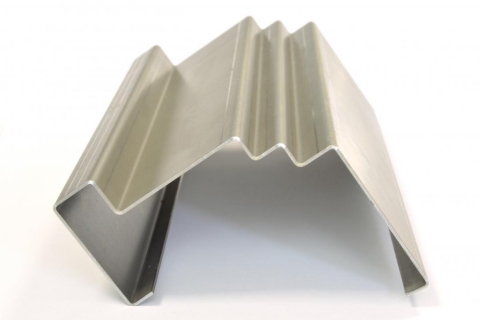

Press Brake Machine Bending Samples

Press brake machines can bend a variety of metal materials such as stainless steel, iron, copper, aluminum, titanium and carbon steel. As small as non-ferrous metals, ferrous metal sheets, automobiles and ships, electrical appliances, decoration, kitchen utensils, cabinets, elevator cabinet doors, cutting and bending processing; as large as the aerospace field, CNC shearing machines and sheet metal bending machine are playing an increasingly important role.

We provide free proofing service, welcome to consult.

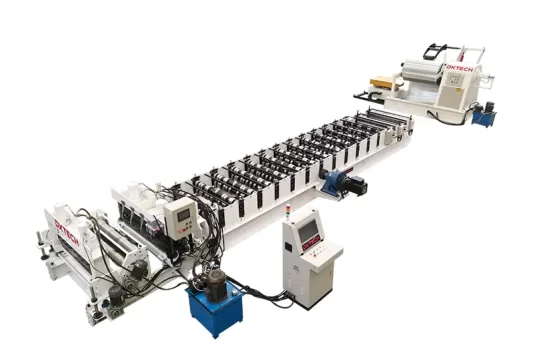

Features of High quality Electric Servo Press Brake Machine 8FT Sheet Metal Brake for Sale in United States/USA

1. Advanced Closed – loop Control Imported internationally renowned electro – hydraulic servo valves and grating rulers form a closed – loop control system. This ensures high – precision control, enhancing the overall performance and reliability of the machine.

2. Precise Slide Operation The slider has high – precision position feedback, enabling accurate and stable operation. It features excellent synchronization performance, ensuring high bending accuracy and high slider repeat positioning accuracy.

3. Flexible Rear Gauge Mechanism The rear stop mechanism can be configured with multiple rear stop axes according to customer needs. This provides more complete functions, allowing for greater flexibility in material positioning.

4. Integrated Hydraulic System The hydraulic system adopts an integrated control system. This reduces pipeline installation, effectively addresses oil leakage issues, and ensures the stable operation of the machine tool. Additionally, it gives the machine a more scientific and aesthetically pleasing appearance.

5. Automatic Deflection Compensation The hydraulic deflection automatic compensation mechanism eliminates the impact of slider deformation on workpiece quality. The numerical control system automatically adjusts the compensation amount, ensuring convenient and accurate operation.

Application of Electric Servo Press Brake Machine

Main technical parameters

| Model | DX-PB-125T/2500 |

| Control System | DE-15 |

| No. of Axes | 4+1 (Y1, Y2, X, R+V) |

| Nominal Force | 1250kN |

| Bending Length | 2500mm |

| Distance between Columns | 2080mm |

| Throat Depth | 400mm |

| Slider Stroke | 200mm |

| Main Motor Power | 7.5kW |

| Voltage | 380V 50Hz 3PH |

| Operation Environment | Temperature -20 ~ +50℃ Humidity 20~85% |

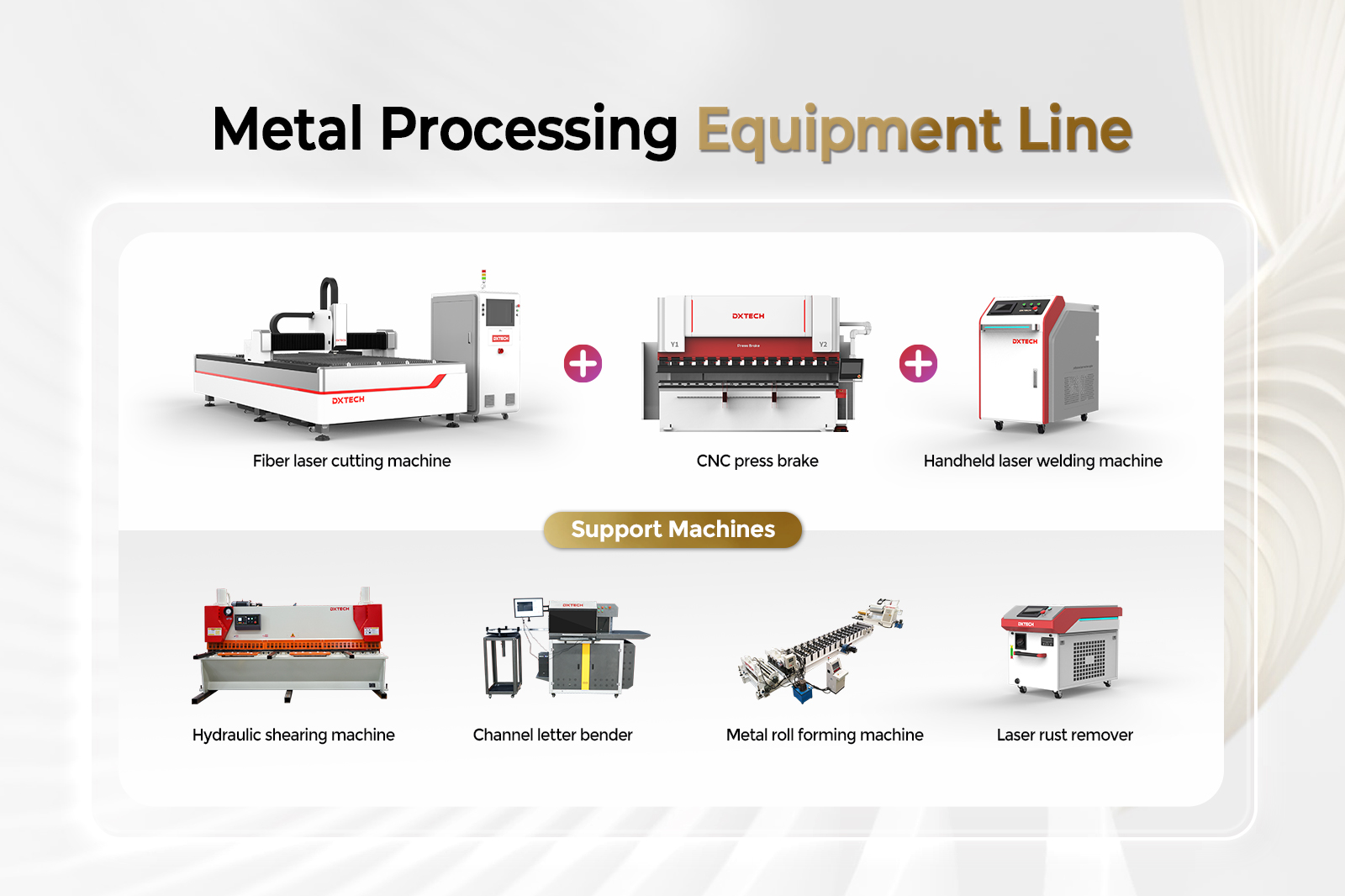

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.