Hydraulic CNC Press Brake Metal Bending Machine Features

1. High Precision, Efficiency & Stability

Features high bending precision, rapid working speed, high efficiency, operational safety, and stable performance.

2. Robust High-Precision Welded Frame

The anti – knock frame is made of welded – steel plates. The entire frame is tempered to reduce deformation. It is processed at once by a large – scale CNC milling machine to ensure high precision.

3. International-Brand Parts & CNC System

Equipped with international – brand parts and CNC system.

4. Standardized CNC-Produced Components

Has a visual operating system, which is easy to operate, convenient, multi – functional, and practical.

5. High-Caliber Professional Assembly Team

All parts are produced at the CNC production center according to standard drawings.

Hydraulic CNC Press Brake Metal Bending Machine Videos

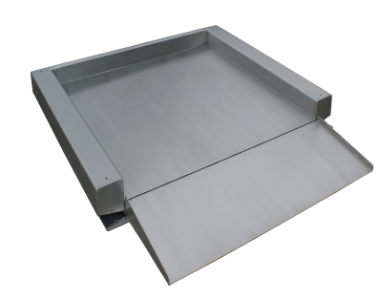

Hydraulic CNC Press Brake Metal Bending Machine Applications

The High performance Hydraulic CNC Press Brake Metal Bending Machine for Sale in Kenya represents a mechanical apparatus deployed for the precise bending and folding of metal sheets. This machine enjoys widespread utility across diverse sectors, including metal fabrication and manufacturing, construction and building industries, automotive production, and sheet metal processing. It has the remarkable ability to transform metal sheets into the desired configurations. This functionality empowers the creation of a wide array of metal products and structural components. By doing so, it effectively caters to the design specifications and processing needs of different industrial verticals, ensuring seamless integration into various manufacturing and construction workflows.

Hydraulic CNC Press Brake Metal Bending Machine Specifications

| Model | 125T/3200mm | |

| CNC System | ESA S630 | |

| Nominal Force | 1250kN | |

| Table Length | 3200mm | |

| Distance Between Columns | 1560mm | |

| Throat Depth | 350mm | |

| Slider Stroke | 200mm | |

| Opening Height | 460mm | |

| Oil Pump | 16F | |

| Main Motor Power | 7.5KW | |

| Control Accuracy | ±0.01mm | |

| Number Of Control Axes | 3 Axes (Y1, Y2) | |

| Electrical Components | Schneider | |

| Ball Screw | TBI | |

| Back Gauge Guide Rail | HIWIN |

DXTECH Quality Assurance

2 Years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Customer feedback

Laser Machine Upgrade

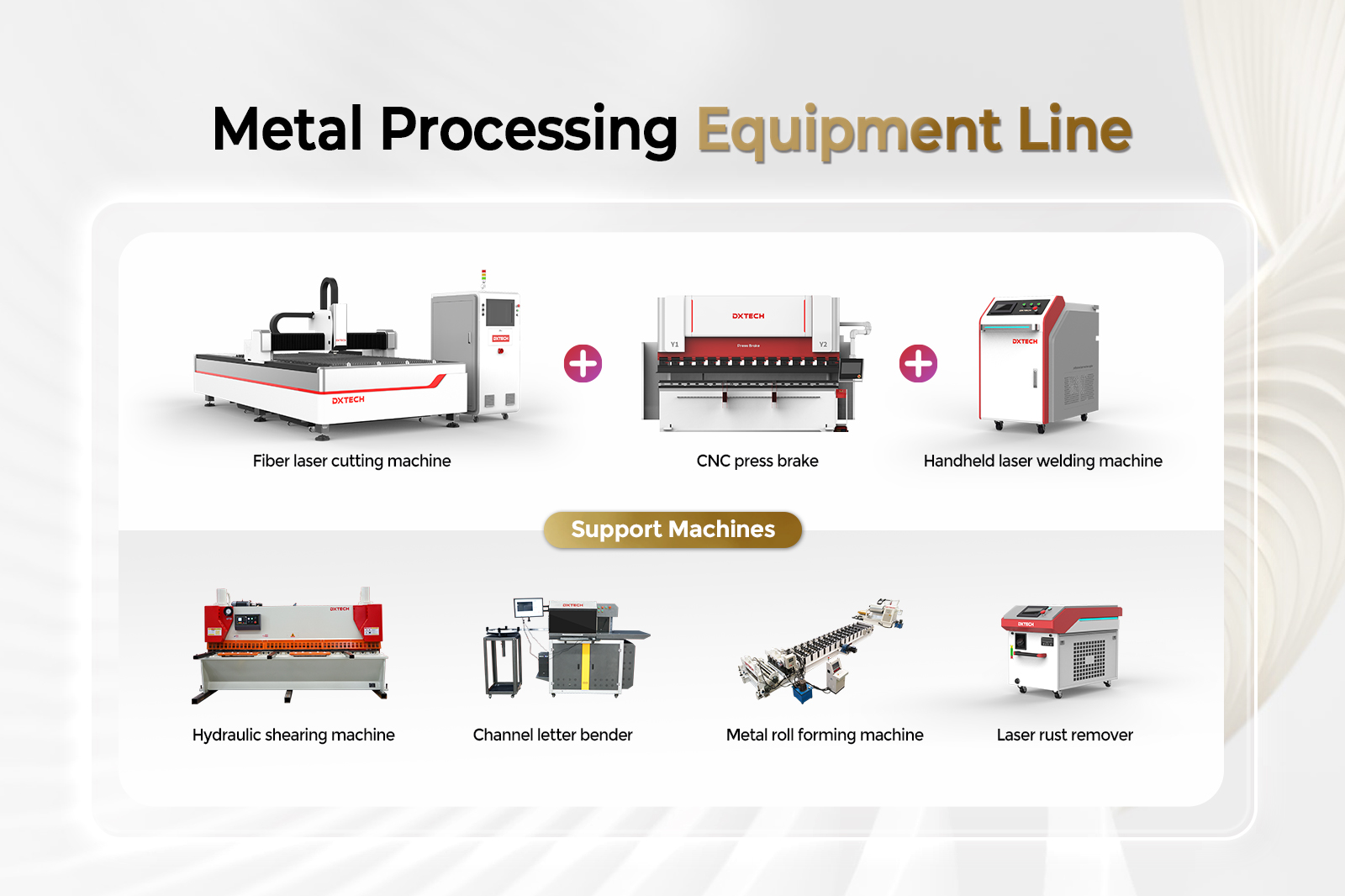

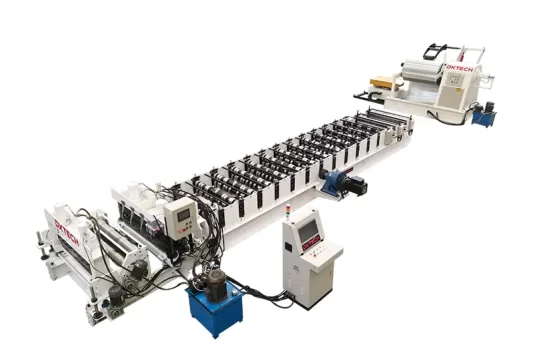

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

▐ Laser Machine FAQ

Of course. From laser configuration to automation systems, we provide tailor-made solutions to meet your specific needs.

It can cut various metals including stainless steel, carbon steel, aluminum, brass, copper, galvanized steel, and alloys.

2-year warranty for the main machine, 1-year for laser source and key components—covers manufacturing defects, excluding wear parts.

Standard models: 7-15 days; custom models: 30-45 days (varies by configuration and shipping location).

Laser source: annual check; lenses and nozzles: clean/replace every 200-300 hours; guide rails: lubricate monthly.

Reviews

There are no reviews yet.