In the HVAC manufacturing industry, the demand for metal processing is growing rapidly. For example, precision is critical, with many components requiring tolerances of 0.1 millimeters or less. Additionally, complex and irregularly shaped parts often need to be processed to meet the diverse design requirements of HVAC systems.

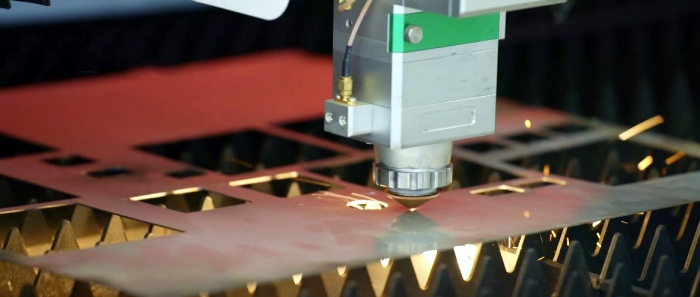

The application of fiber laser cutting machine for metal cutting is also becoming increasingly widespread. Their high-energy laser beams can precisely cut various metals without material loss, meeting the precision, speed, and flexibility required for HVAC manufacturing. This article will explore the six key applications of fiber laser cutting machines in HVAC manufacturing, with a focus on their characteristics.

Ⅰ Current Development Requirements and Pain Points in the HVAC Industry

New Metal Cutting Requirements in the HVAC Industry

1. Higher Precision Demands

As HVAC systems trend toward greater energy efficiency, ductwork precision standards have tightened. Per GB 50243, energy-saving ducts must have an air leakage rate ≤3%, requiring duct components to be cut with tolerances ≤0.05mm. Even minor deviations can cause joint gaps, reducing system efficiency.

2. Advanced Material Needs

Corrosion-resistant materials like 316 stainless steel are increasingly used—especially in harsh environments (coastal, industrial areas)—with annual consumption growing 25%. Its high reflectivity challenges traditional cutting tools, but next-gen fiber laser cutters handle such materials cleanly and precisely.

3. Small-Batch, Multi-Variety Production

Custom HVAC projects now make up a larger market share, demanding equipment that adapts quickly to varying specs. Ideal machines should enable changeovers within 5 minutes, supporting efficient production of small batches—from unique residential ducts to specialized commercial air handlers.

4. Green Manufacturing Standards

Tighter global regulations on VOC emissions (e.g., US EPA standards) are phasing out traditional oily cutting processes, which release significant VOCs. Fiber laser cutting, a dry process with zero VOC emissions, meets these eco-friendly requirements.

Three Key Limitations of Traditional Cutting in HVAC Manufacturing

1. Inadequate Precision

Traditional methods like plasma cutting, with tolerances as large as ±0.5mm, fail to meet strict ductwork standards. Poorly fitting joints from imprecise cuts cause air leakage—for example, in large commercial systems, this can boost energy consumption by up to 20% as blowers compensate for pressure loss.

2. Challenges with Complex Parts

Irregular components (e.g., custom air vents) are hard to produce efficiently with traditional cutting. Multiple steps—cutting, shaping, finishing—are required, lengthening production time and raising error risks.

3. High Material Waste

Sheet-metal shears, limited to straight-line cutting, generate up to 20% waste due to excessive clamping/positioning material. With rising raw material costs, this inefficiency significantly increases HVAC manufacturers’ production expenses.

C.Limitations of Traditional Processes in HVAC Manufacturing

1. Sheet-Metal Shearing Machines

Limited to straight-line cutting, they cannot handle complex shapes in HVAC components—such as spiral fan casings or curved duct fittings. This restricts their use for parts like blower wheels.

2. Plasma Cutting

With a 1–2mm heat-affected zone (HAZ), it often deforms thin sheets (≤1mm), such as evaporator fins. Deformed fins disrupt airflow and heat transfer, lowering HVAC system performance.

3. Flame Cutting

Flame cutting has a large heat-affected zone (3–5mm) and poor precision (tolerances of ±1mm or more). When cutting HVAC components like thin-gauge duct sections, excessive heat causes warping, while imprecise edges require extra finishing. This slows production and undermines the tight fits needed for energy-efficient systems.

III. Advantages of Fiber Laser Cutting Machines

1. Precision Control

Fiber laser cutting machines for metal cutting achieve incision perpendicularity ≤0.05mm/m, ensuring tight fits for duct flanges (minimizing air leakage) and precise evaporator fins (enhancing heat transfer via even, close arrangement).

2. Material Compatibility

Fiber laser cutting machines for metal cutting handle diverse HVAC materials: 0.3–20mm galvanized steel (ducts), 316 stainless steel (corrosion-resistant parts), and 6061 aluminum alloy (lightweight components). Single-machine versatility eliminates multiple setups, streamlining production.

3. Efficiency Improvement

With continuous cutting speeds up to 140m/min, fiber laser cutting machines for metal cutting suit HVAC mass production—e.g., over 1,000 air-conditioning sheet-metal parts daily. High speed boosts output and shortens lead times to meet tight deadlines.

4. Cost Optimization

Eliminating mold costs and pairing with automation reduces expenses, especially for small-batch custom parts (e.g., air vents), cutting production costs by up to 60% via reduced labor and no mold-making fees.

IV. Fiber Laser Cutting Machines for Metal Cutting 6 Applications in HVAC

1. Air - Conditioning Systems

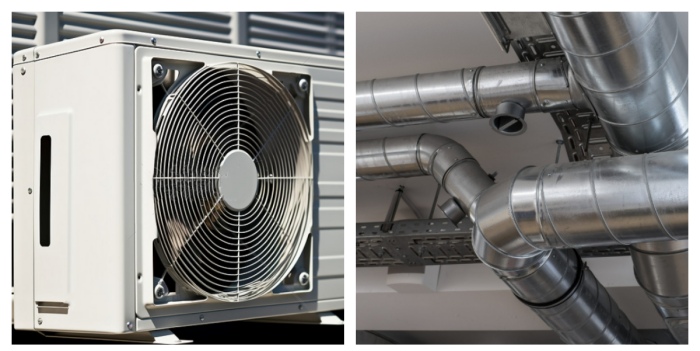

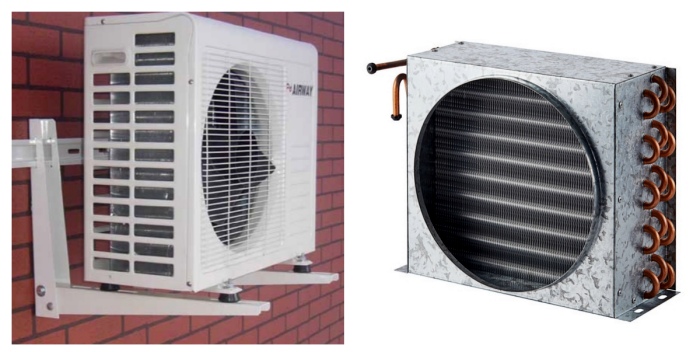

1. Air – Conditioning Units

- Fiber laser cutting machines for metal cutting are used to process metal sheets for the outer casing, which is typically made of 1 – 3mm galvanized steel. The precise cutting ensures a smooth surface and accurate dimensions, providing protection against external elements.

- The internal support frame, made of 5 – 8mm carbon steel, is also cut with high precision. The laser can create holes and notches for easy assembly.

- For the hinge of the access door, which is usually made of 2mm stainless steel, fiber laser cutting provides a clean and durable cut, ensuring smooth operation of the door over a long period.

2. Ductwork

In the production of ductwork, fiber metal laser cutting machine can handle both straight – run ducts and complex components such as elbows and reducers. The material used can be 0.8 – 2mm cold – rolled steel or aluminum sheet. For irregular – shaped ducts required for complex installation environments, the laser can follow intricate cutting paths, ensuring a perfect fit during installation.

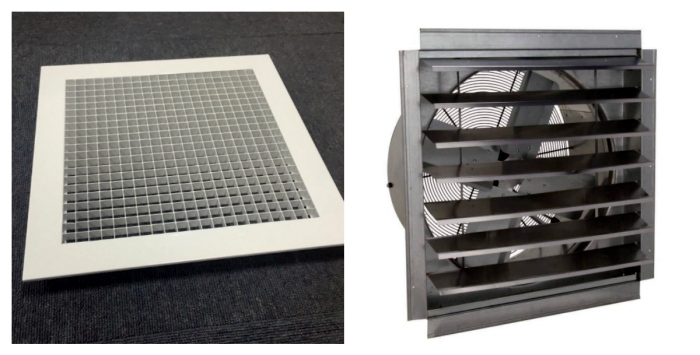

3. Air Outlets and Return Grilles

These components, made of 1mm aluminum or stainless steel, often have precise hole patterns to control the direction and speed of air flow. Fiber laser cutting can accurately create these holes, ensuring consistent air distribution in the conditioned space.

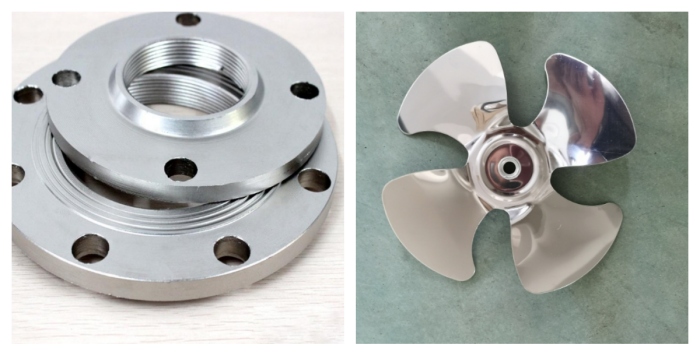

4. Compressor Components

- The installation brackets, made of 6 – 10mm carbon steel, are cut to precise shapes to securely hold the compressor. The laser – cut edges provide a better fit for bolts and other fasteners.

- The vibration – damping pads, which are 1 – 2mm rubber – coated metal sheets, are also processed using fiber laser cutting. The precise cutting ensures that the pads fit perfectly around the compressor, reducing vibration and noise.

5. Condensers and Evaporators

- For the finned tubes, which are usually made of 0.3 – 0.5mm aluminum, fiber laser cutting machine for metal cutting can create fins with precise dimensions. The high – precision cuts increase the surface area for better heat transfer.

- The headers, made of 3 – 5mm copper alloy, are cut to fit the finned tubes accurately. The laser – cut ends ensure a tight connection, minimizing refrigerant leakage.

6. Chillers and Heat Pumps

- The outer casing of chillers and heat pumps, made of 3 – 6mm stainless steel, is cut with fiber laser to provide a corrosion – resistant and durable enclosure.

- The internal baffles, made of 2 – 4mm carbon steel, are cut to control the flow of refrigerant. The precise cutting of the baffles ensures efficient heat exchange and proper refrigerant circulation.

2. Fresh Air Systems

1. Fresh Air Handling Units

- Cabinet panels, made of 1.5–3mm galvanized steel, are cut to form a sturdy enclosure. Fiber laser cutting machine for metal cutting ensures tight panel fits, preventing air leakage.

- Internal partitions (1–2mm aluminum sheet) separate filtration, heat-exchange, and fan areas. The laser creates precise cutouts for component installation.

2. Filtration Systems

Filter frames (1–2mm stainless steel, used for HEPA and activated-carbon filters) require precise slots for seal installation. Fiber laser cutting produces these slots with high accuracy, ensuring a tight seal and efficient filtration.

3. Duct Connections

Flanges (2–3mm steel) and flexible duct joints (1mm aluminum) are cut for airtight connections. Laser-cut surfaces provide better sealing than traditional methods, reducing air leakage in the fresh air system.

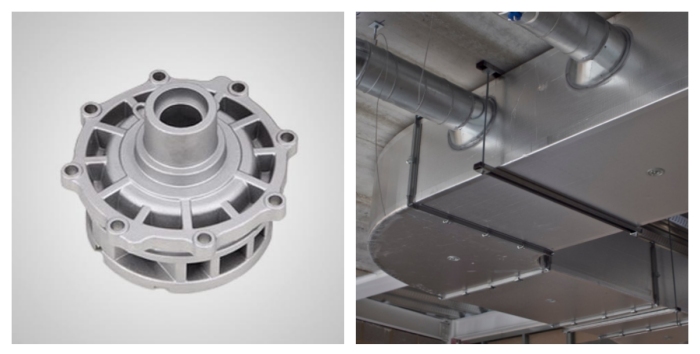

4. Fans and Blowers

- Impellers (3–5mm steel) are cut to precise shapes for balanced operation. Laser-cut edges reduce air turbulence, boosting fan efficiency.

- Motor-mounting plates (4–6mm carbon steel) are cut to fit motors accurately. Precise holes and cutouts on the plates enable easy installation and secure motor fastening.

3. Exhaust Systems

1. Exhaust Fans

- The fan housing, made of 2–4mm galvanized steel, is cut into a streamlined shape for high-airflow performance. Fiber laser cutting machine for metal cutting can create complex housing shapes, optimizing air intake and exhaust.

- Blade components, made of 3–5mm aluminum alloy, are cut with high precision. Laser-cut blades ensure smooth rotation and efficient air movement.

2. Exhaust Ducts

Ducts (1–3mm steel) and their fittings—including fire dampers with 2.5mm carbon steel blades—are cut to meet safety regulations. Fiber laser cutting machine for metal cutting creates necessary openings and connections while preserving the integrity of fire-damper blades.

3. Ventilation Grilles

These grilles, made of 1–2mm stainless steel, serve both decorative and functional roles. Fiber laser cutting machine for metal cutting can produce customized hole patterns to reduce noise while enabling proper air circulation, and they can be cut to fit various wall and ceiling installations.

4. Industrial Exhaust Hoods

For large-scale industrial exhaust hoods, the metal shell (3–6mm carbon steel) and reinforcing ribs (5–8mm steel) are cut using fiber laser technology. Precise cutting ensures the hood’s structural integrity—critical for handling high-volume exhaust in industrial settings.

4. Air Purification Systems

1. Air Purifier Housings

The housing (1–2mm stainless steel) and front panel with control-panel cutouts (0.8–1.5mm aluminum) are cut to form an aesthetically pleasing, functional enclosure. Fiber metal laser cutting machine creates precise cutouts for installing control buttons and displays.

2. Filter Cartridge Housings

These housings—cylindrical or rectangular, made of 1.5–3mm steel—hold UV-C lamps and electrostatic precipitators. Fiber metal laser cutting machine produces necessary slots and holes for component installation, ensuring proper alignment and function.

3. Air Distribution Plates

Perforated diffusers (1mm aluminum) evenly distribute purified air in clean rooms or medical facilities. Fiber laser cutting machine for metal cutting creates uniform holes on the plates, ensuring consistent air distribution.

4. Fan Components

Low-noise fan blades (2–4mm composite metal) and motor brackets (3–5mm steel) are cut for quiet operation. Precise cutting of the blades reduces air turbulence, while motor brackets are cut to fit motors securely.

5. Heating Systems

1. Radiators and Heaters

For radiators, finned panels (0.5–1mm steel) are cut to increase surface area for better heat dissipation. Water inlet and outlet ports (2–3mm brass) are also cut to fit the system. Fiber laser cutting machine for metal cutting ensures accurate dimensions for both panels and ports, enhancing overall radiator performance.

2. Boiler Components

The boiler shell (3–6mm heat-resistant steel) and internal heat exchanger (4–8mm stainless steel) are cut to precise specifications. Laser-cut surfaces ensure proper fit and efficient heat transfer in the boiler system.

3. Pipes and Valves

Flange plates (6–10mm carbon steel) and valve bodies (5–8mm cast iron) are cut for hot-water or steam distribution. Fiber laser cutting machine for metal cutting creates accurate holes and connections, ensuring leak-free operation.

4. Heat Pumps

Refrigerant-line brackets (2–4mm aluminum) and coil-support grilles (1–2mm steel) are cut for heat pump outdoor units. Precise cutting ensures refrigerant lines are properly supported and coils are securely held, improving heat pump efficiency.

6. Air - Conditioning and Refrigeration Systems

1. Chillers

The evaporator housing (5–10mm stainless steel) and tube sheet (8–12mm carbon steel) are cut for large-scale refrigeration systems. Fiber laser cutting machine for metal cutting handles these thick materials precisely, ensuring the integrity of chiller components.

2. Fan-Coil Units

Indoor-unit housing panels (1–2mm galvanized steel) and coil-mounting brackets (3–5mm steel) are cut to fit fan-coil components. Laser-cut parts enable easy installation and proper component alignment.

3. Cooling Towers

The structural frame (6–10mm steel) and packing-support grilles (3–5mm PVC-coated steel) are cut to support the cooling tower’s heat-dissipation function. Fiber laser cutting machine for metal cutting produces strong, durable frames and grilles, capable of withstanding harsh outdoor conditions.

4. Refrigerant Lines

Copper-pipe brackets (1–2mm steel) and insulation clamps (0.8–1mm aluminum) are cut for neat, organized installation. Precise cutting ensures refrigerant lines are properly supported and insulated.

5. Thermostatic Valves

Valve bodies (3–5mm brass) and actuator-mounting plates (2–4mm steel) are cut for temperature control. Fiber laser cutting machine for metal cutting creates accurate holes and surfaces for actuator installation, ensuring precise temperature regulation.

V. Selection Considerations for HVAC Manufacturers

Power Adaptation

1. For thin-walled parts (≤3mm) (e.g., ventilation ducts, air outlets):

Opt for 1000–3000W models. A 2000W laser balances cutting speed and energy efficiency, ideal for high-volume production of thin galvanized steel or aluminum components.

2. For thick parts (5–10mm) (e.g., boiler shells, fan supports):

Choose 6000W+ lasers to ensure one-pass cutting of thick carbon steel or 316 stainless steel, maintaining precision and reducing rework.

Key Optional Configurations

1. Duct-specific software

Automatically unfolds circular/rectangular duct designs and optimizes nesting, boosting material utilization by 15% vs. manual programming.

2. Scratch-resistant worktable

Protects galvanized steel coatings from damage, eliminating rework for corrosion resistance in humid environments.

3. Automatic loading/unloading

Enables 24/7 operation for high-output facilities (1000+ daily parts), cutting labor costs by 30% and minimizing downtime.

4. Power failure recovery

Resumes cutting from breakpoints, preventing waste of expensive materials (e.g., 316 stainless steel) and avoiding rework on precision parts like evaporator fins.

VI. Conclusion

Fiber laser cutting machine for metal cutting have become indispensable equipment in the HVAC manufacturing industry, meeting the sector’s evolving demands for precision, flexibility, and sustainability. From energy-efficient ductwork to corrosion-resistant 316 stainless steel components, their ability to process a wide range of materials and complex shapes—combined with speed and cost advantages—makes them central to modern HVAC production.

Whether producing custom air outlets, large duct systems, or high-precision evaporator components, fiber laser cutting delivers consistent quality and efficiency. As a 14-year manufacturer of fiber metal cutting equipment, DXTECH has designed multiple cutting solutions tailored to the HVAC industry.

If you are interested, contact our technical team for a free customized cutting solution assessment tailored to your specific HVAC components, optimizing your HVAC production line.