In the rapidly developing clean energy sector—encompassing energy storage, photovoltaics, wind power, and electric vehicles—the demand for high-precision metal processing is growing. The production of components for these new energy applications requires extremely high precision, with tolerances typically within ±0.1 mm. This is because the associated equipment features complex and sensitive characteristics. For instance, in energy storage systems, even the smallest deviation in the manufacturing process of battery components can result in performance issues.

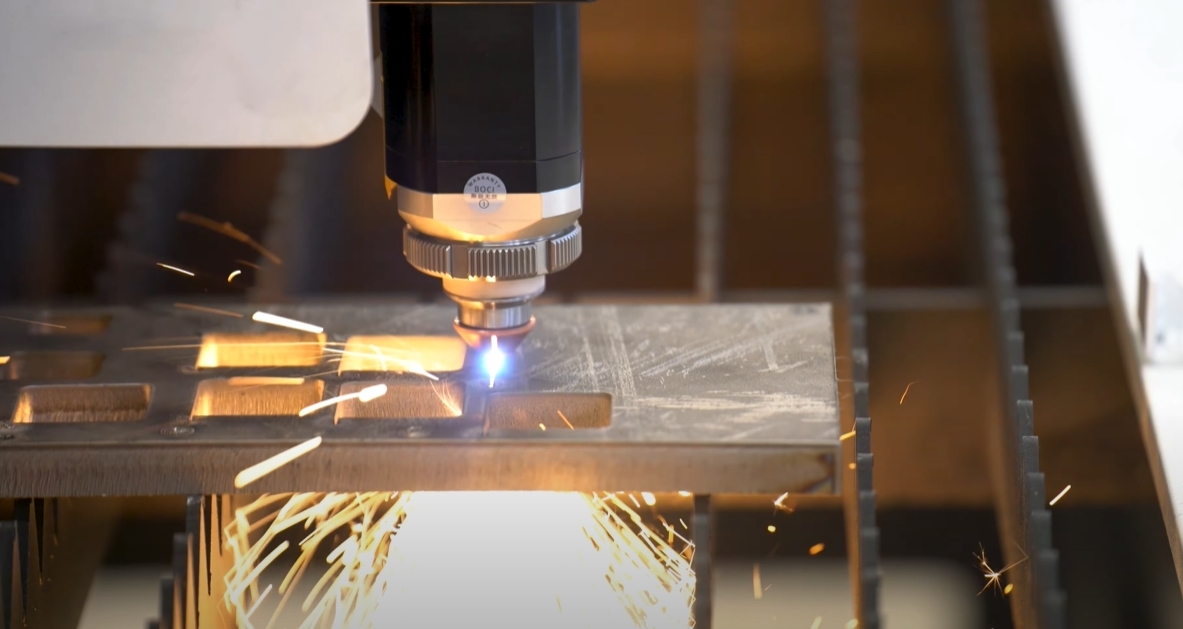

Fiber laser cutting machine for metal for metal are increasingly being used in the new energy industry. With cutting speeds of up to 100 meters per minute and cutting accuracy of ±0.02, they excel at processing complex-shaped metal parts. In short, fiber laser cutting machines have become key equipment for the large-scale production of new energy equipment, enabling manufacturers to meet market demand for high-volume, high-quality products.

Ⅰ Special Requirements for Metal Processing in the New Energy Industry

1. Material Diversity

The new energy industry utilizes a wide range of metal materials, with stainless steels like 304 and 316 being the most prevalent. 304 stainless steel, valued for its excellent corrosion resistance and formability, makes up roughly 30% of the metal used in energy storage equipment casings. For photovoltaic module frames, 316 stainless steel is preferred for its superior corrosion resistance in harsh outdoor environments, accounting for about 20% of applications.

Aluminum alloys—especially the 6061 series—are also highly popular. Thanks to their high strength-to-weight ratio, 6061 aluminum alloy is widely used in wind turbine blades and new energy vehicle components, comprising approximately 40% of wind turbine blade frame materials and 35% of new energy vehicle body structures.

Though more costly, titanium alloys are critical for applications demanding high strength, low weight, and exceptional corrosion resistance. In aerospace-related new energy components—such as parts in high-altitude wind power systems—they make up around 10% of total metal usage.

2. Process Standards

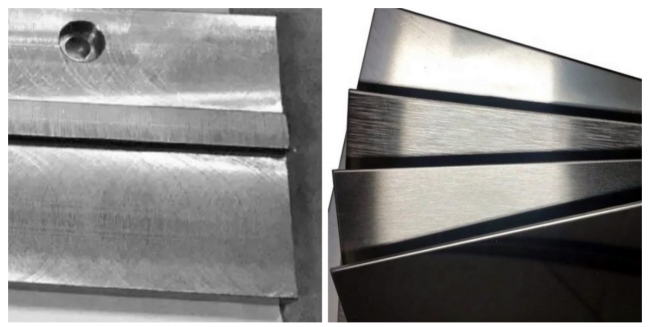

- Surface Smoothness

In energy storage batteries, surface smoothness is of utmost importance. A surface roughness (Ra) of ≤1.6μm is typically required. If the surface of the battery shell or internal components is too rough, it can cause short – circuit risks. For example, in lithium – ion batteries, rough surfaces may lead to the penetration of the separator by sharp metal protrusions, resulting in an internal short – circuit and potential safety hazards. - Structural Strength

For wind turbine towers, before welding, the cut – edge flatness requirements are extremely strict. The deviation of the cut – edge should be within ±0.2mm. This is because any significant unevenness in the cut – edge can lead to stress concentrations during the welding process, reducing the overall structural strength of the wind turbine tower. A structurally weak tower is more vulnerable to strong winds and mechanical vibrations, which can lead to tower collapse and pose a serious threat to the safety of the wind power plant and the surrounding environment.

3. Mass Production Efficiency

The new energy vehicle industry, in particular, has an extremely high demand for mass production efficiency. Many new energy vehicle manufacturers need to cut more than 5000 body components per day. This high – volume production requirement means that the metal processing equipment used must be able to operate continuously and efficiently. Any delay or inefficiency in the cutting process can bottleneck the entire vehicle production line, leading to increased costs and reduced output.

Ⅲ Advantages of Fiber Laser Cutting Machines

Three Major Pain Points in New Energy Equipment Processing

1. High Material Waste Rate

Traditional metal processing techniques often result in a high material waste rate. In some cases, especially when using methods like mechanical cutting, the waste rate can reach up to 15%. This is because these methods may require large amounts of material for clamping and positioning, and the cutting process itself may generate a significant amount of scrap due to imprecise cuts.

2. Difficulty in Processing Complex Parts

New energy equipment often contains complex – shaped components. Traditional processing methods struggle to accurately and efficiently produce these parts. For example, parts with intricate curves and small details are extremely challenging to manufacture using traditional techniques, often resulting in low – quality products or high rejection rates.

3. Inadequate Precision

Meeting the high – precision requirements of the new energy industry is a major challenge for traditional processing methods. The tolerance levels that can be achieved are often much larger than the ±0.1mm required in many new energy applications, leading to components that do not fit together properly or do not function as intended.

Limitations of Traditional Processing Technologies in the New Energy Industry

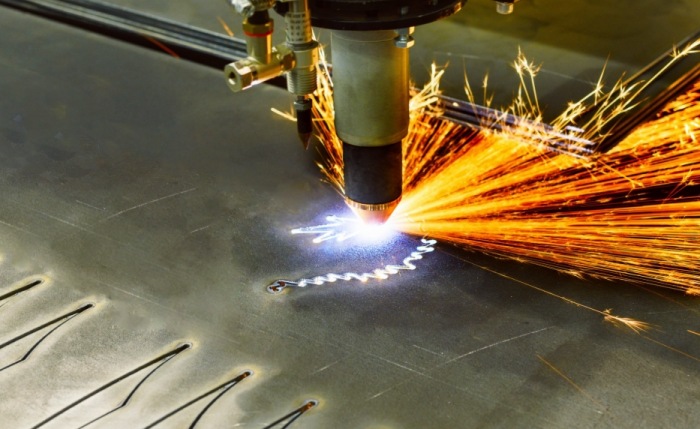

1. Plasma Cutting

Plasma cutting has a relatively low precision, with an accuracy of only ±0.5mm. In the manufacturing of battery packs, this level of precision is insufficient. For battery pack enclosures, a tight seal is required to prevent the ingress of moisture and dust, which could damage the battery cells. The large tolerance of plasma cutting makes it difficult to ensure a proper seal, increasing the risk of battery failure.

2. Water Cutting

Water cutting is a slow process, with a cutting speed of only 10 – 15m/min. In an industry where mass production is key, such as the new energy vehicle industry, this slow speed is a major drawback. It simply cannot keep up with the high – volume production requirements, leading to long production cycles and high costs.

3. Stamping Process

The mold replacement cycle for the stamping process is relatively long, typically requiring 3 to 4 weeks. In the new energy industry, due to the constant updating and replacement of product models, this relatively long cycle time has become a significant limiting factor. For example, new energy vehicle manufacturers often need to quickly adapt to new design requirements or technological advances. The relatively long mold replacement cycle of the stamping process makes it difficult to respond in a timely manner, putting them at a disadvantage in competition.

Advantages of Fiber Laser Cutting Machines

1. High Speed

Fiber laser cutting machine for metal can achieve cutting speeds of up to 140m/min. This high speed significantly reduces the production time for each part. For example, in the production of photovoltaic module frames, a fiber laser cutting machine can cut a large number of frames in a short time, greatly increasing the production efficiency of the entire production line.

2. High Precision

Fiber laser cutting machine for metal can achieve a precision within ±0.02mm, easily meeting the tight tolerance requirements of the new energy industry. In the manufacturing of energy storage battery components, this high precision ensures that the components fit together perfectly, reducing the risk of electrical malfunctions due to misalignment.

3. Suitability for Complex Metal Parts Processing

Fiber laser cutting machine for metal are highly flexible and can easily handle the processing of complex-shaped metal parts. Through advanced computer control systems, they can precisely follow complex cutting paths to produce complex components suitable for new energy equipment, such as complex-shaped heat sinks in new energy vehicle charging stations.

Ⅳ Six Scenario – Based Solutions for Fiber Laser Cutting

Fiber laser cutting machine for metal plays a critical role in processing key components across new energy sectors, addressing specific material and structural demands. Below is a detailed breakdown of their applications in core equipment manufacturing:

1. Energy Storage Equipment: Precision Cutting for Core Components

Energy storage systems (e.g., lithium-ion battery packs, electrochemical storage cabinets) rely on laser cutting for multiple critical parts:

- Battery casings: Thin-walled stainless steel (0.5–2mm) or aluminum alloy (1–3mm) casings require deformation-free cutting. Fiber laser cutter for metal (1000W, 5000Hz) achieve clean, burr-free edges with <0.1mm deformation, preventing short circuits caused by metal shavings.

- Busbars & current collectors: Copper or aluminum busbars (thickness 2–5mm) need precise slotting and perforation for electrical connectivity. Fiber laser cutting machine for metal ensures ±0.05mm accuracy, avoiding resistance irregularities.

- Storage cabinet frames: 304 stainless steel profiles (3–8mm) for cabinet skeletons are cut into complex shapes (e.g., mounting holes, ventilation slots) at speeds up to 50m/min, accelerating assembly line throughput.

2. Photovoltaic Equipment: Versatile Cutting for Solar Module Components

Photovoltaic (PV) systems depend on laser cutting for consistent performance in outdoor environments:

- Aluminum alloy brackets: PV bracket (6061 aluminum, 2–4mm thick) require multi-spec designs (length 1.2–3m) to adapt to different installation angles. Fiber laser cutting machine for metal enable rapid program switching (3 minutes per spec) without molds, supporting small-batch, high-variety production.

- Solar panel frames: 316 stainless steel frames (1.5–3mm) with precision notches for glass panel fitting. Laser cutting ensures Ra≤1.6μm surface smoothness, resisting corrosion in humid or coastal areas.

- Inverter enclosures: Cold-rolled steel (2–5mm) enclosures for inverters need cutouts for cable entry and heat dissipation. Fiber laser cutting machine for metal handle intricate patterns (e.g., hexagonal vents) with high repeatability, ensuring IP65 waterproof standards.

3. Wind Power Equipment: Thick-Plate and Large-Structure Cutting

Wind turbines (onshore/offshore) demand robust cutting for heavy-duty components:

- Tower flanges: High-strength steel (Q355ND, 20–50mm thick) flanges require precise bevel cutting (30°–45°) for welding to tower sections. 6000W fiber lasers cut 30mm steel at 1.2m/min with <0.2mm bevel tolerance, ensuring leakproof welds.

- Blade root reinforcements: Glass fiber-reinforced plastic (GFRP) composite plates (5–15mm) bonded to blade roots need laser trimming to match curvature, avoiding stress concentration during rotation.

Nacelle frames: Large-scale steel structures (10–20mm thick) for housing generators and gearboxes.Fiber laser cutting machine for metal with 8m worktables cut 6m-long beams with nested layouts, reducing material waste to <5% (vs. 15% with plasma cutting).

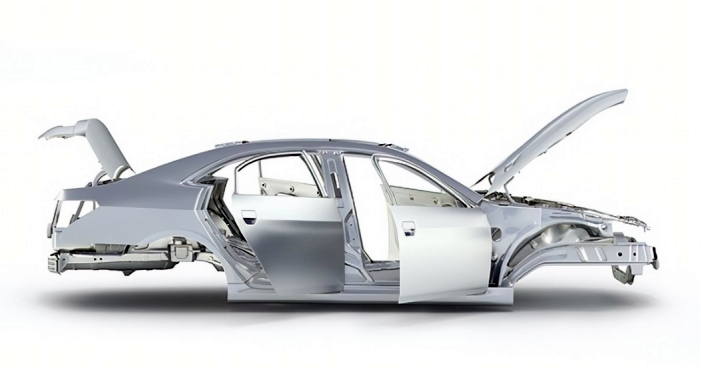

4. New Energy Vehicles: Lightweight & Strength Optimization for Automotive Parts

Electric vehicles (EVs) and hybrid models leverage laser cutting to balance efficiency and safety:

- Aluminum alloy body panels: Aluminum alloy (1–3 mm) is used for doors, hoods, and chassis components. Laser cutting technology enables complex contours (such as crash box contours) with minimal heat-affected zones (HAZ <0.1 mm). Compared to steel, it reduces weight by 15% while maintaining the same impact resistance.

- Battery pack trays: High-strength steel (HSLA, 2–4mm) or aluminum (3–6mm) trays with precision drainage holes and cell positioning slots. Laser cutting ensures tight tolerances (±0.08mm) for waterproof sealing (IP67 standard).

- Motor stators/rotors: Silicon steel sheets (0.3–0.5mm thick) for EV motors require intricate slotting (width 1–3mm) to minimize energy loss. Fiber laser cutting machine for metal cut 100 sheets/min with burr-free edges, enhancing motor efficiency by 3–5%.

5. Hydropower Equipment: Heavy-Duty Cutting for Large-Scale Components

Hydropower facilities rely on laser cutting for durability in high-pressure water environments:

- Turbine runners: Stainless steel (316L, 10–30mm thick) blades with aerodynamic curves. 12kW fiber lasers cut 20mm steel at 2m/min, achieving smooth surfaces (Ra≤3.2μm) to reduce water resistance.

- Penstock pipes: Carbon steel pipes (8–20mm thick) for water conveyance require precise beveling and flange drilling. On-site laser cutting (via mobile units) adapts to field conditions, avoiding transportation issues with pre-cut large diameters (≥2m).

- Gate structures: Structural steel (Q355B, 15–50mm) for sluice gates, cut into grid patterns or lifting lugs. Laser cutting ensures uniform stress distribution, critical for withstanding water pressure up to 10MPa.

6. Hydrogen Energy Equipment: Clean Cutting for High-Purity Systems

Hydrogen storage and transportation systems demand contamination-free cutting to prevent explosions or corrosion:

- Hydrogen tank shells: 316L stainless steel (5–10mm thick) for high-pressure tanks (35–70MPa). Laser cutting produces oxide-free edges (no secondary grinding) that meet ISO 13400 cleanliness standards, avoiding hydrogen embrittlement.

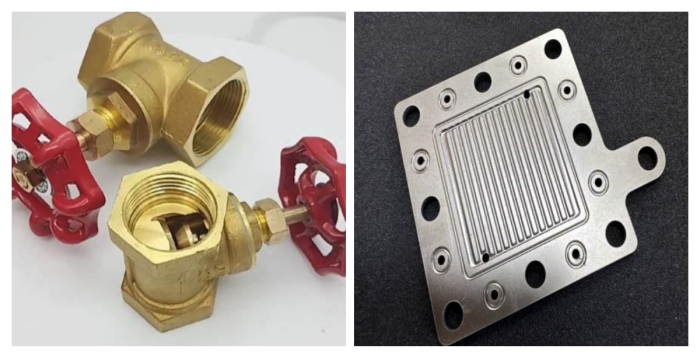

- Pipelines & valves: Copper-nickel alloy (Cu-Ni 90/10, 2–8mm) pipes and valve bodies require leakproof weld prep. Laser cutting creates precise groove angles (e.g., 60° V-grooves) with <0.1mm deviation, ensuring hermetic sealing.

- Electrolyzer plates: Titanium alloy (Gr.2, 1–3mm) plates with micro-perforations (0.5–2mm diameter) for water electrolysis. Fiber laser cutting machine for metal drill 10,000+ holes per minute with ±0.02mm accuracy, optimizing hydrogen production efficiency.

Each application leverages fiber laser cutting’s strengths—speed, precision, and flexibility—to address the unique challenges of new energy equipment manufacturing, from thin-walled casings to heavy-duty structural components.

Ⅴ Selection Guide: How to Match Fiber Laser Cutting Machines for the New Energy Industry

1. Power Selection Formula

Power recommendation:

Thin plates (<3 mm): 1000-3000 W

Medium-thick plates (3-10 mm): 6000-12000 W

2. Additional Functions

- Automatic Loading and Unloading System

Given the high – volume production requirements of the new energy industry, an automatic loading and unloading system is highly recommended. This system can work continuously for 24 hours, greatly improving production efficiency. It can automatically load raw materials onto the cutting table and unload the finished parts, reducing the need for manual labor and minimizing the risk of human – error – induced production delays. - Dust Removal Device

In many new energy manufacturing environments, especially in clean rooms where the production of high – precision components such as energy storage batteries and hydrogen energy equipment takes place, a dust removal device is essential. A high – quality dust removal device can effectively remove the dust and debris generated during the laser cutting process, maintaining the cleanliness of the production environment and ensuring the quality of the products.

Ⅵ Conclusion

Fiber laser cutting machine for metal has become an increasingly important metal processing tool in the new energy industry. Its exceptional ability to meet the industry’s demands for high precision, high speed, and complex part processing has significantly driven the development of new energy equipment manufacturing. By enabling more efficient production, higher-quality products, and innovative design solutions, fiber laser cutters for metal are contributing to the growth of the new energy industry.

If you are in the new energy industry and seeking the most suitable fiber laser cutting solution for your production needs, consider DXTECH. With over 14 years of expertise in laser equipment manufacturing, DXTECH has designed and manufactured a variety of laser cutting machine series tailored to different industries. Our expert team is ready to provide personalized recommendations and industry-leading laser cutting solutions. Please feel free to contact us for more information.