Recently, we were honored to receive video feedback from a client in Bosnia and Herzegovina, in which the client highly praised the DXTECH 1530SPT fully enclosed sheet and tube metal fiber laser cutting machine they purchased, stating that the equipment greatly assisted them in exploring new markets. For this, the client especially expressed their sincerest gratitude to us.

CLIENT BACKGROUND

DXTECH 1530SPT fully enclosed sheet and tube metal fiber laser machine in Bosnia and Herzegovina

DXTECH 1530SPT fully enclosed sheet and tube metal fiber laser machine in Bosnia and Herzegovina

This Bosnian and Herzegovinian client is an expert in metal manufacturing and can assist clients with customized metal manufacturing projects, including stainless steel, mild steel, and aluminum fabrication. There is a particularly urgent need to cut metal plates and tubes. Based on a thorough understanding of the client’s needs and European environmental standards, our sales team carefully recommended the 1530SPT fully enclosed sheet and tube metal fiber laser cutting machine, meeting the client’s production and processing requirements for stainless steel, carbon steel, and other metallic materials.

After in-depth communication and a detailed understanding of the client’s production needs, the DXTECH sales team established a close cooperative relationship with the client. We not only provided comprehensive explanations through one-on-one customized presentations, dissecting the core elements of the 1530SPT fully enclosed sheet and tube metal fiber laser cutting machine such as its structural design, working principle, cutting efficiency, and maintenance, but also innovatively utilized advanced remote video technology to demonstrate in real-time the machine’s cutting performance in actual operation. This initiative greatly enhanced the client’s confidence in the equipment’s performance and provided strong support for their final decision.

HIGH PRAISE FROM THE CLIENT

In the feedback video, the client gave extremely high praise to the 1530SPT fully enclosed sheet and tube metal fiber laser cutting machine. He mentioned that the equipment recommended by the sales team perfectly fits their daily production needs in terms of worktable size and output power, exhibiting unexpected efficiency and precision in both plate and tube cutting operations. Especially when cutting metallic materials with complex shapes and sizes, the cutting accuracy and speed left the client deeply impressed. He specifically emphasized the machine’s protective hood design, which not only effectively ensures the safety of operators but also realizes real-time remote monitoring of the processing process through an integrated monitoring system, greatly enhancing the convenience and transparency of production management.

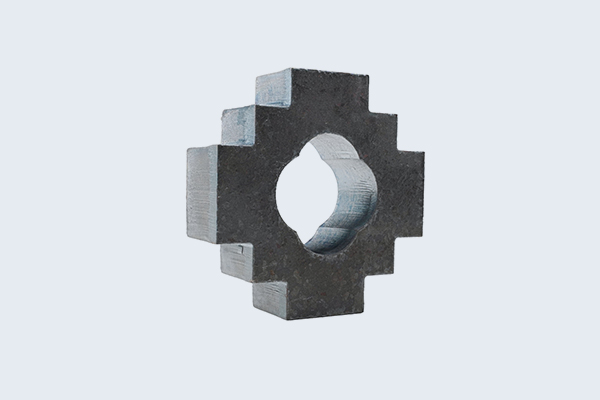

In the video, the client proudly showcased the finished metal plates and tubes processed by the 1530SPT. These finished products ranged from common metal plates, round tubes, and square tubes, to complex shaped tubes, with such fine cutting quality that almost no subsequent grinding was required, directly meeting the client’s stringent requirements for high-quality finished products. The client stated that the cutting capabilities of this machine not only meet their current production needs but also provide strong technical support for their future expansion into new businesses and markets.

It is worth mentioning that the client repeatedly mentioned the professionalism and service spirit of the DXTECH sales team in the video. He expressed that throughout the purchase and installation process, the sales team maintained a high level of patience and enthusiasm, providing comprehensive technical support and after-sales service. Whether it was equipment selection, installation, and commissioning, or later use guidance and maintenance, the sales team demonstrated extremely high professional competence and a sense of responsibility, winning widespread praise from the client and their team.

ADVANTAGES OF DXTECH 1530SPT FULLY ENCLOSED STAINLESS STEEL AND CARBON STEEL LASER CUTTING MACHINE

As an all-in-one plate and profile cutting machine, the 1530SPT fully enclosed laser cutting machine can easily meet the cutting requirements of various metal profiles such as square tubes, round tubes, U-shaped steel, and angle steel. Equipped with a 1000w-6000w laser, the machine can flexibly adjust the laser power according to different materials and thicknesses, achieving high-speed and efficient cutting, which is highly favored by the metal processing industry.

1. Fully Enclosed Protective Cover

The external part of the machine adopts a fully enclosed design, effectively protecting users and the machine from laser and metal swarf hazards, while reducing noise and dust pollution. The internal dual-camera setup allows users to monitor the machine’s working status and processing effects through the display screen at any time.

2. Dual-Function Capability

The equipment integrates plate and profile cutting into one unit, enabling the cutting of various metal profiles such as round tubes, square tubes, flat bars, square steels, and U-shaped steels without the need to change equipment or accessories. This significantly saves acquisition costs and space and improves productivity.

3. Dual Workbench Design

Adopting an independently developed interchangeable high and low workbench, it achieves rapid changeovers with a changeover time of less than 15 seconds. This significantly shortens loading and unloading times, reduces costs, and enhances work efficiency.

4. Integrated Mobile Electrical Cabinet

Electrical components and the laser source are integrated into an external mobile electrical cabinet, facilitating user maintenance and repairs. Additionally, a waterproof powder extension design is adopted to effectively extend the service life of electrical components.

5. Efficient Cutting

Using a gear and rack drive system, the dual-drive structure ensures rigidity and precision, shortening feeding time. Equipped with a 1000-6000W laser, the machine can flexibly adjust the laser power according to different materials and thicknesses, achieving high-speed and efficient cutting.

sheet tube laser cutting machine sample

Sheet tube laser cutting machines are capable of cutting a wide variety of metal materials such as stainless steel, aluminum, brass, copper, titanium, carbon steel, and various alloys. Not only can it process metal sheets, but it can also process round metal tubes, square metal tubes, etc. The thickness of the material that can be cut depends on the power of the laser and other machine specifications, but generally speaking, the material range that can be cut by the plate and tube laser cutting machine is 0.5-25mm.

We provide free proofing service, welcome to consult.

DXTECH Quality Assurance

2 Years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Customer feedback

The fact that the DXTECH 1530SPT fully enclosed sheet and tube metal fiber laser cutting machine has won such high praise in the Bosnian and Herzegovinian market is the result of our team’s collective efforts. In the future, we will continue to strive in research and development, providing more efficient, environmentally friendly, and intelligent metal processing solutions for clients worldwide!