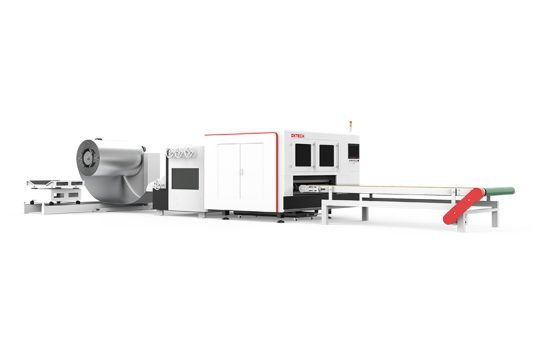

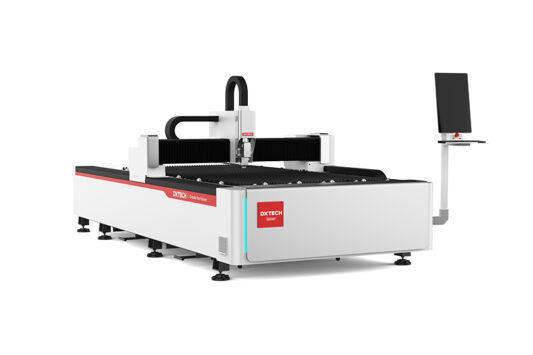

3kw 6kw Affordable Coil Feeding Steel Laser Cutting Machines for Sale in Singapore/SG are widely used in various industries. In the automotive sector, they efficiently cut metal coils into precise parts for vehicle bodies, engines, and chassis. In construction, these machines process coils into components like beams, brackets, and metal panels. The appliance manufacturing industry relies on them to cut coils into parts for refrigerators, washing machines, and other household items. Additionally, they play a crucial role in the production of electrical enclosures, metal furniture, and decorative metal products, ensuring high – precision and consistent results.

▍3kw 6kw Affordable Coil Feeding Steel Laser Cutting Machines Advantages

1. Tailored Solutions for Varied Metalworking Demands

Our automatic coil laser cutting equipment stands out with its remarkable adaptability. It’s engineered to modify cutting settings with pinpoint accuracy, accommodating coils made from diverse metals and in multiple thicknesses. Whether you need basic straight cuts, curved arcs, or elaborate designs, this machine delivers consistent results, effortlessly meeting the unique and customized requirements of every client.

2. High – Capacity Unwinding for Elevated Output

Equipped with a robust unwinding mechanism, this cutting machine revolutionizes material handling. It significantly accelerates the single feeding process, doubling the efficiency compared to standard models. With the ability to handle heavy – duty coils weighing up to 8T, 10T, or 15T, it breaks through the capacity limitations of conventional feeding systems. This allows for processing larger quantities of material in a single run, leading to a substantial increase in overall productivity.

3. Streamlined Operations with Minimal Manual Effort

The continuous coil cutting and batch processing capabilities of our laser cutter are game – changers. By reducing the need for constant human supervision and intervention, it alleviates the burden on the workforce. This not only cuts down on labor costs but also ensures that the quality of output remains high, making it a cost – effective and efficient choice for businesses.

4. Seamless, Around – the – Clock Production

Designed for non – stop operation, our laser cutting machine can work continuously for 24 hours a day. The seamless coordination between the cutting and feeding functions allows it to operate while the coil is in motion. The coil conveying system works in harmony, constantly feeding in new material and removing processed pieces. This smooth, uninterrupted workflow saves precious time and maximizes production efficiency, enabling businesses to meet tight deadlines and high – volume demands.

▍Automatic Feeding Coil Steel Laser Cutting Machine with Autofocus Videos

▍Automatic Feeding Coil Steel Laser Cutting Machine with Autofocus Specifications

| Model | DXTECH-1530FC | DXTECH-1540FC | DXTECH-2040FC |

| Working area (mm) | 1515*3030 | 1515*4040 | 2020*4040 |

| Max. acceleration | 1.5G | 1.5G | 1.5G |

| Worktable | Rolling blade | Rolling blade | Rolling blade |

| Positioning accuracy | ±0.05mm | ±0.05mm | ±0.05mm |

| Repositioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Laser power | 1kW – 3kW | 1kW – 3kW | 1kW – 3kW |

| Coil sheet thickness | 0.5-3mm | 0.5-3mm | 0.5-3mm |

| Machine bed | Plate welded bed | Plate welded bed | Plate welded bed |

| Laser | Multiple options | Multiple options | Multiple options |

| Focusing method | Auto/manual | Auto/manual | Auto/manual |

| X/Y-axis max. linkage speed | 140m/min | 140m/min | 140m/min |

| Leveling speed | ≤20m/min | ≤20m/min | ≤20m/min |

| Coil weight | ≤15t | ≤15t | ≤15t |

▍DXTECH Services

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

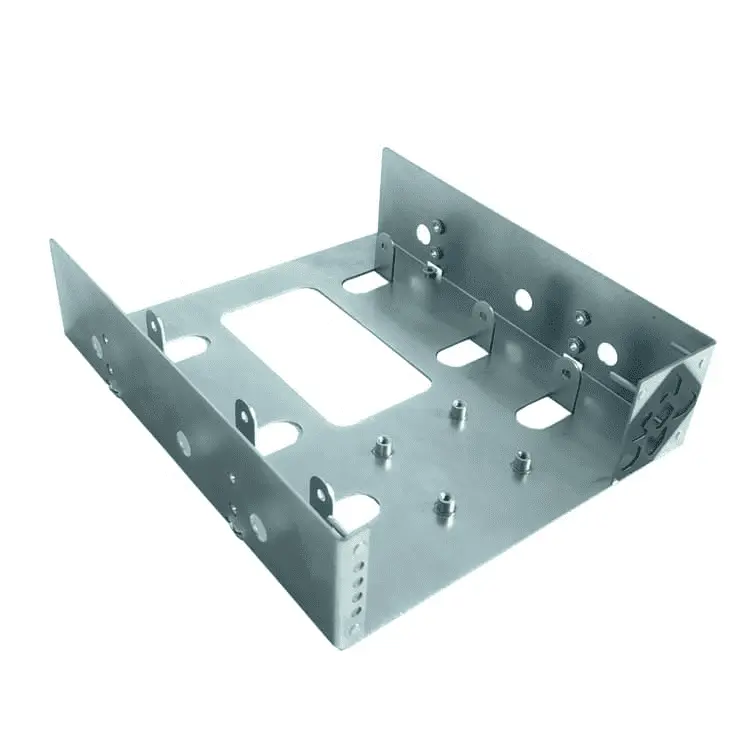

▍Automatic Feeding Coil Steel Laser Cutting Machine with Autofocus Samples

We provide free proofing service. Welcome to consult.

▍Customer Reviews

Laser Machine Upgrade

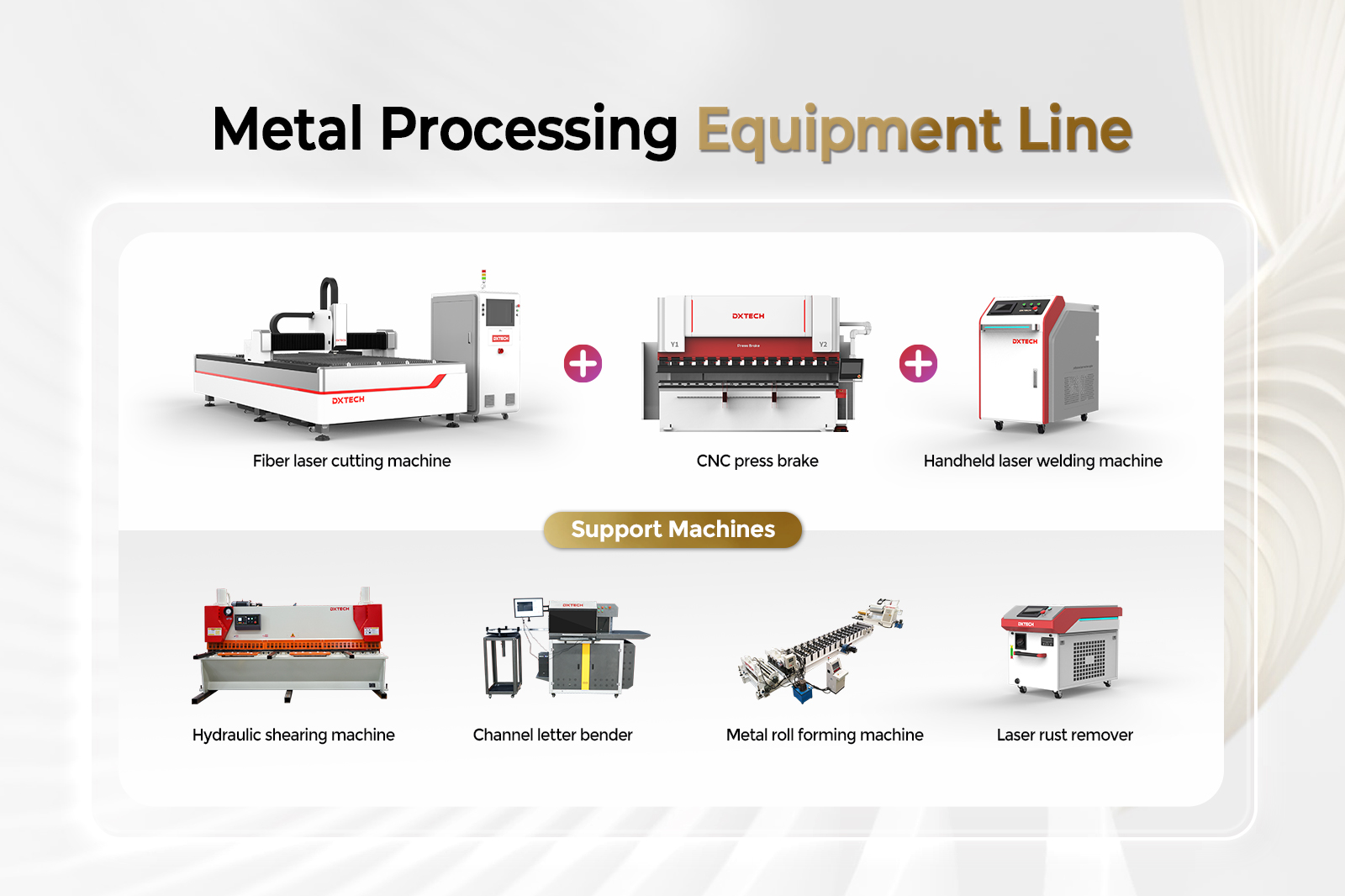

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.