Video

Features:

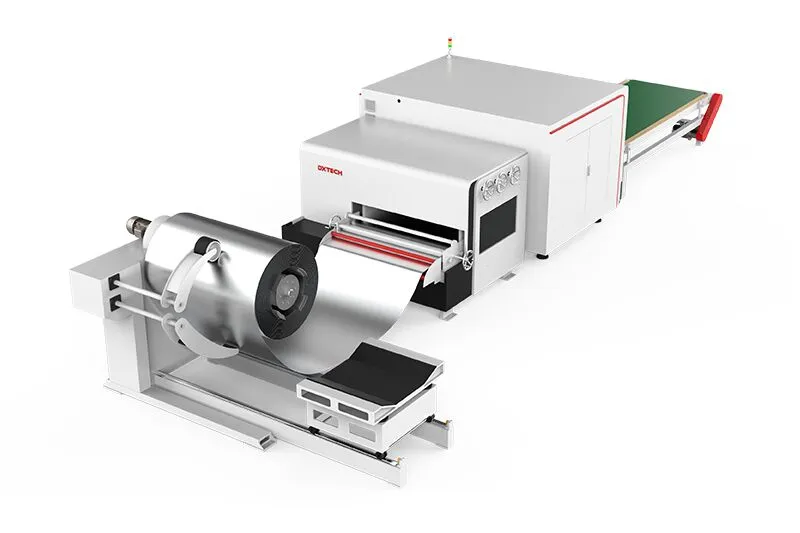

The automatic fiber laser coil cutting machine enables continuous and automated processing, achieving a 50% increase in productivity compared to traditional punching methods. Suitable for processing metal coils with a thickness range of 0.5mm to 2mm, it is widely applied across multiple core manufacturing sectors. In the automotive industry, it is used to produce body structure components, chassis parts, and engine housings; in the electrical equipment manufacturing sector, it commonly processes distribution cabinets and transformer housings. Moreover, it finds applications in the fabrication of ventilation ducts and various other industrial fields.

Advantages:

1. Heavy-Duty Feeding Capacity

Feeds up to 20 tons—6x the capacity of standard 3-ton systems—delivering 6-fold efficiency gains over conventional equipment.

2. Enhanced Stress Relief Mechanism

Post-uncoiling, the leveling machine flattens sheets to eliminate internal stress, resulting in ultra-flat surfaces for optimal cutting performance.

3. Ultra-Precision Transmission System

Features an ultra-precision drive system ensuring sheet transport accuracy within ±0.5mm for high-precision processing.

4. Fully Automated Production Cycle

Achieves end-to-end automation—from feeding, uncoiling, leveling, cutting to unloading—enabling 100% material utilization with zero waste.

5. 80% Productivity Boost

The automatic feeding system eliminates manual handling, increasing output by 80% while minimizing downtime.

DXTECH Service

DXTECH operates three major production facilities covering 75,000 m². With over 50 national patents and international certifications (ISO, FDA, UL, CE), its products are exported to 180+ countries. The company has sales networks in 20+ nations (e.g., US, Spain, Bosnia, Australia) and local offices in Bosnia, Spain, and Turkey for on-site installation, training, and support.

Founded in 2009, DXTECH has a full-value chain system spanning R&D, production, sales, and after-sales. Services include free online training and dispatch of specialists for on-site equipment installation, commissioning, and operational guidance.

Components of Automatic Fiber Laser Coil cutting machine

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

Weihong LS1500/LS3000 Laser Cutting Control System

Weihong laser cutting control system is a software for plane laser cutting. It supports AI, DXF, PLT and international standard G codes generated by Mater Cam, Type3, Wentai, etc.

Except common editing and typesetting functions, it has unique processing sequence browsing and powerful material database to load the specification directly. Besides, operators can control the system through wireless handheld box and Ethernet conveniently.

We provide free proofing service. Welcome to consult.

Reviews

There are no reviews yet.