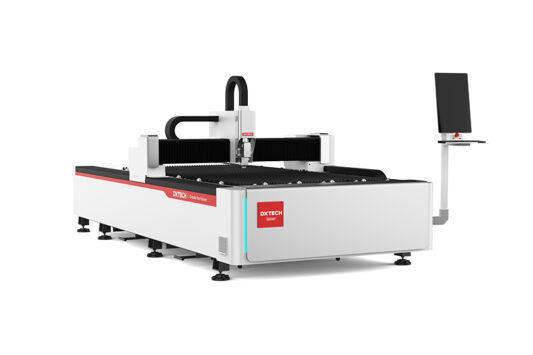

Fiber Laser Cutting Machine for Stainless Steel Laser Cutting Applications

The DXTECH 1500W CNC Laser Acrylic Letter Cutting Machine, which also serves as a Fiber Laser Cutting Machine for Stainless Steel Laser Cutting, has become a hit among small and medium – sized metal processors. This machine is a real workhorse, capable of efficiently cutting various materials such as stainless steel, carbon steel, and aluminum plates. Its cutting speed is impressively fast, and it leaves no dross behind, ensuring high – quality results. Moreover, it’s not just limited to metal cutting; it can also precisely cut acrylic letters, adding to its versatility. Thanks to its outstanding performance, it has found wide application in multiple industries. Whether it’s mechanical processing, where precision parts need to be cut, parts cutting for manufacturing, decoration projects that demand intricate designs, or the advertising industry that requires creative and accurate acrylic letter cutting, this DXTECH laser cutting machine is the go – to choice for businesses looking to enhance their productivity and output quality.

Fiber Laser Cutting Machine for Stainless Steel Laser Cutting Advantages

1. High – Quality Components for Reliable Cutting

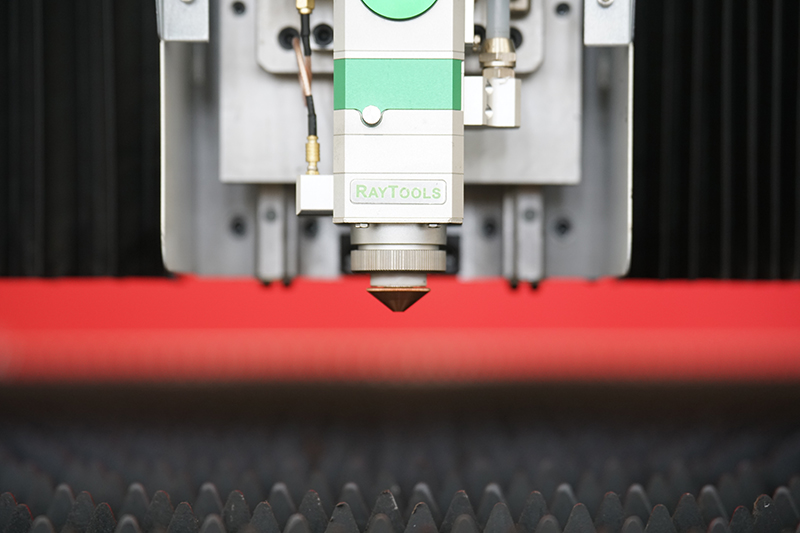

The fiber laser cutting machine is equipped with top – quality spare parts and a control system. These are vital for ensuring continuous, stable, and safe cutting. An industrial water cooler and a gas regulating valve are also part of the setup. The water cooler keeps the laser source at the right temperature to prevent overheating, while the gas regulating valve ensures accurate cutting gas supply for high – quality cuts.

1. Intelligent CNC System for Precise Control

The machine’s intelligent CNC system is easy to configure. It allows for precise control of the whole cutting process. With a wide range of adjustable parameters, it can meet the distinct needs of different materials. Parameters such as laser power, cutting speed, and cutting gas pressure can be adjusted according to the job requirements. Laser power determines energy input for melting materials, cutting speed affects efficiency and cut quality, and cutting gas pressure helps remove molten material.

1. Tubular Welded Structure: Multiple Benefits

The machine has a tubular welded structure with many advantages. It offers high rigidity, enabling it to resist external forces without much deflection. This rigidity ensures stable operation and consistent cutting results. It also has great resistance to deformation, even with long – term or heavy – duty use. Maintenance is simpler due to the structure design, and it can maintain high precision, making it suitable for various precision – cutting tasks.

Fiber Laser Cutting Machine for Stainless Steel Laser Cutting Specifications

| Model | 1530 AFL |

| Working area (mm) | 1550×3050 |

| Table bearing capacity | 600KG |

| Max. linkage speed | 60m/min |

| Max. linkage acceleration | 0.8G |

| Positioning accuracy | 0.03mm |

| Repositioning accuracy | 0.02mm |

| Machine bed | Tube welded |

| Beam | Aluminum |

| Laser | Reci 1000W, 2000W |

| Laser head | Raytools |

| Focusing method | Manual |

DXTECH Services

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

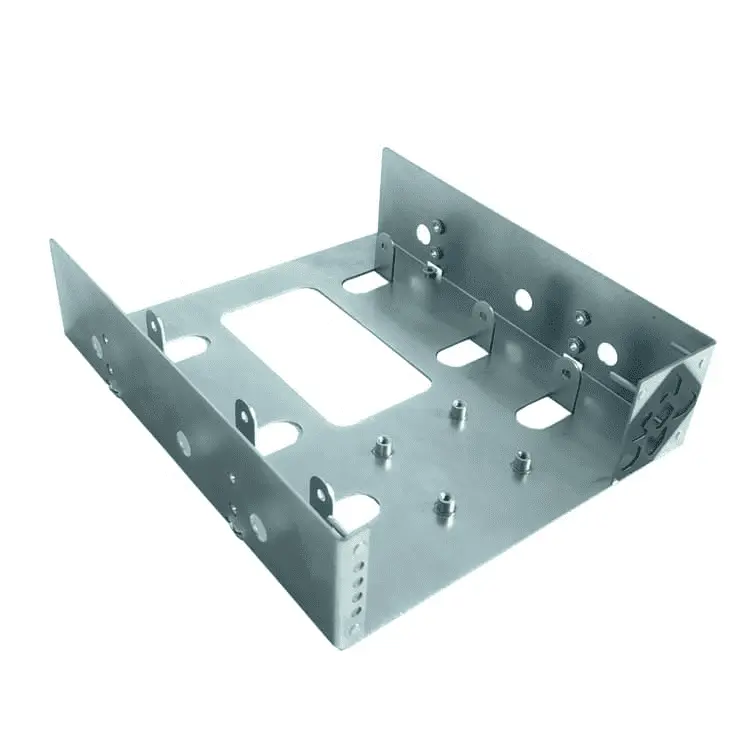

Fiber Laser Cutting Machine for Stainless Steel Laser Cutting samples

We provide free proofing service. Welcome to consult.

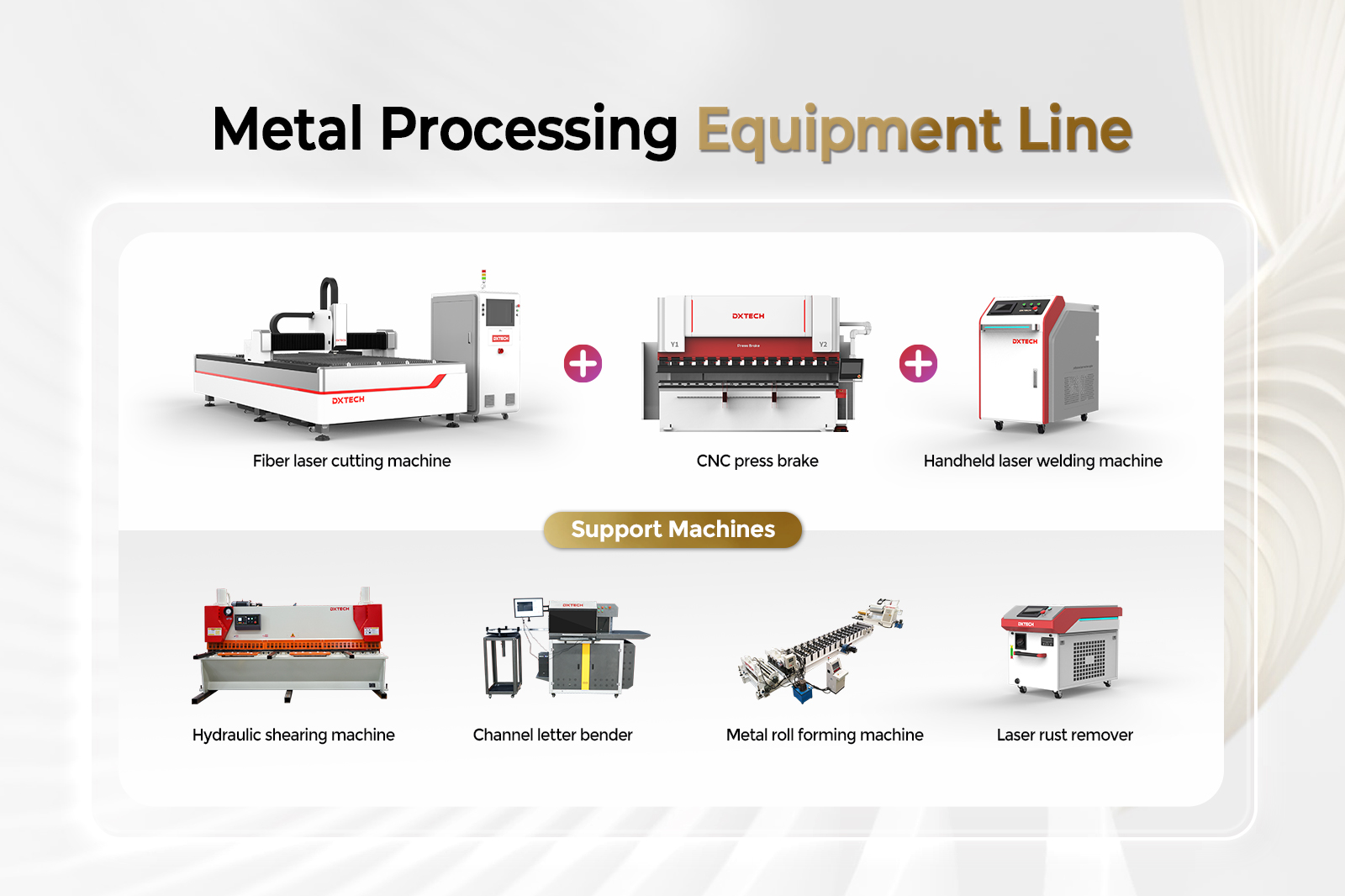

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.