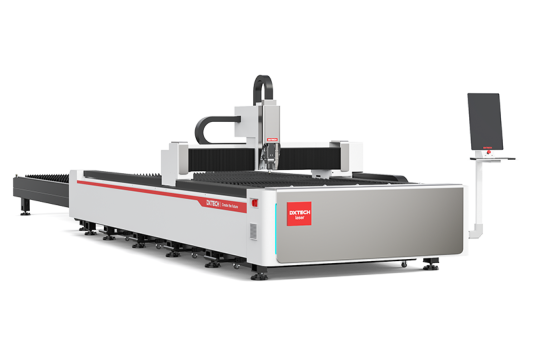

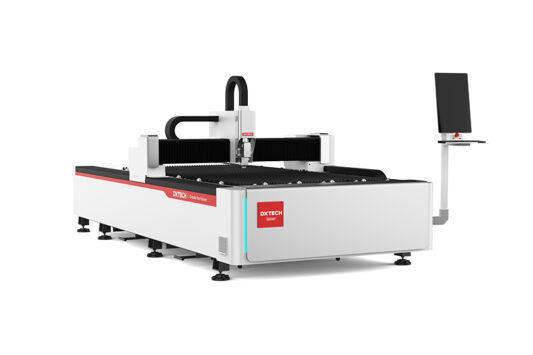

Exchange Table CNC Laser Cutting Machine for Steel Sheet Aluminum Sheet Laser Cutting for Sale in Netherlands, Czech Republic/CZ, Kosovo/XK is mainly applicable to stainless steel, carbon steel, galvanized plate, electrolytic plate, brass plate, aluminum plate, manganese steel, various alloy plates, rare metals and other materials for rapid cutting, widely used in sheet metal processing industry, stainless steel kitchenware industry, electrical cabinet industry, large-scale equipment manufacturing, ships, fitness equipment industry, automobile manufacturing and other industries.

Exchange Table CNC Laser Cutting Machine for Steel Sheet Aluminum Sheet Laser Cutting Video

Exchange Table CNC Laser Cutting Machine for Steel Sheet Aluminum Sheet Laser Cutting Advantages

1. High – Performance Transmission: Boosting Production Efficiency

The equipment adopts a gantry double rack and pinion, double servo motor transmission structure. This setup offers high inertia and large torque output, with a maximum acceleration reaching up to 1.0G. Such a powerful transmission system effectively enhances the customer’s production efficiency, enabling faster and more efficient processing.

2. Double Exchange Platform: Labor – Saving and High – Efficiency Operation

Featuring a double exchange platform, it allows for automatic loading and unloading. This not only saves labor but also significantly improves the overall working efficiency. While one platform is being processed, the other can be loaded or unloaded simultaneously, ensuring continuous operation.

3. Advanced Laser Cutting Software: Precision and Speed in One

Equipped with professional laser cutting software, it comes with graphic layout and sharp – corner smoothing processing functions. Moreover, it can realize high – speed punching and fast cutting functions. This software enables operators to easily design and execute complex cutting tasks with high precision and speed.

4. High – Precision Machining: Ensuring Stability and Accuracy

The machine is precision – machined using imported large – scale gantry machine tools and adopts a high – strength square tube welding process. As a result, the geometric accuracy of the machine is maintained within 0.03mm, providing high precision and stability. This ensures that the cutting results are consistent and meet the highest quality standards.

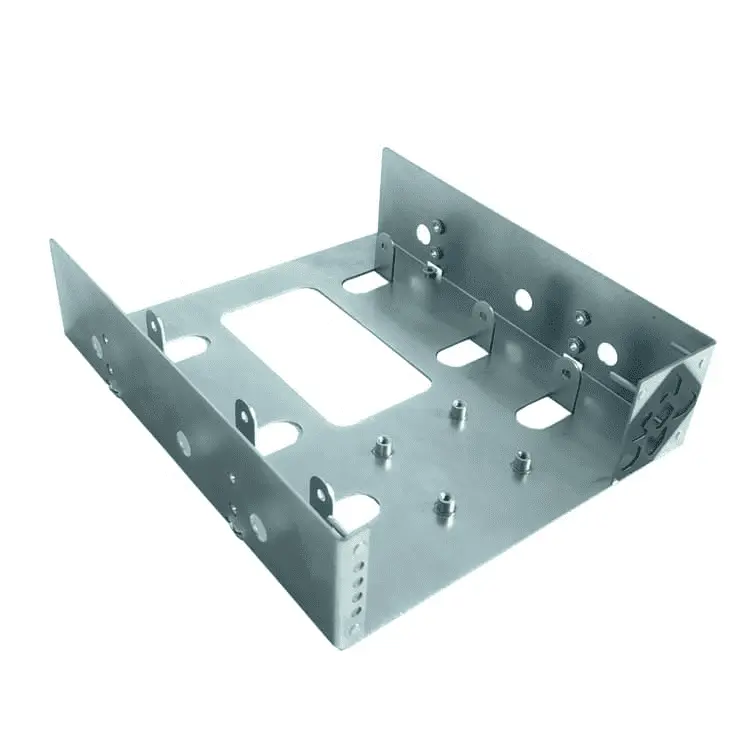

Exchange Table CNC Laser Cutting Machine for Steel Sheet Aluminum Sheet Laser Cutting samples

We provide free proofing service. Welcome to consult.

Exchange Table CNC Laser Cutting Machine for Steel Sheet Aluminum Sheet Laser Cutting Specifiction

| Model | 1530EL | 1560EL | 2560EL |

| Working area | 1515*3030 | 1515*6050 | 2520*6050 |

| Worktable bearing capacity | 800kg | 1300kg | 2200kg |

| Positioning Accuracy | ±0.03mm | ||

| Repositioning accuracy | ±0.02mm | ||

| Max. exchange time | 25s | 35s | 40s |

| Max. acceleration | 1.2G | ||

| Laser power | 1-6kw | ||

| Laser | Multiple options | ||

| Machine bed | Sheet welded bed | ||

| Max Running Speed | 140m/min | ||

DXTECH Quality Assurance

2 Years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Customer feedback

DXTECH Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

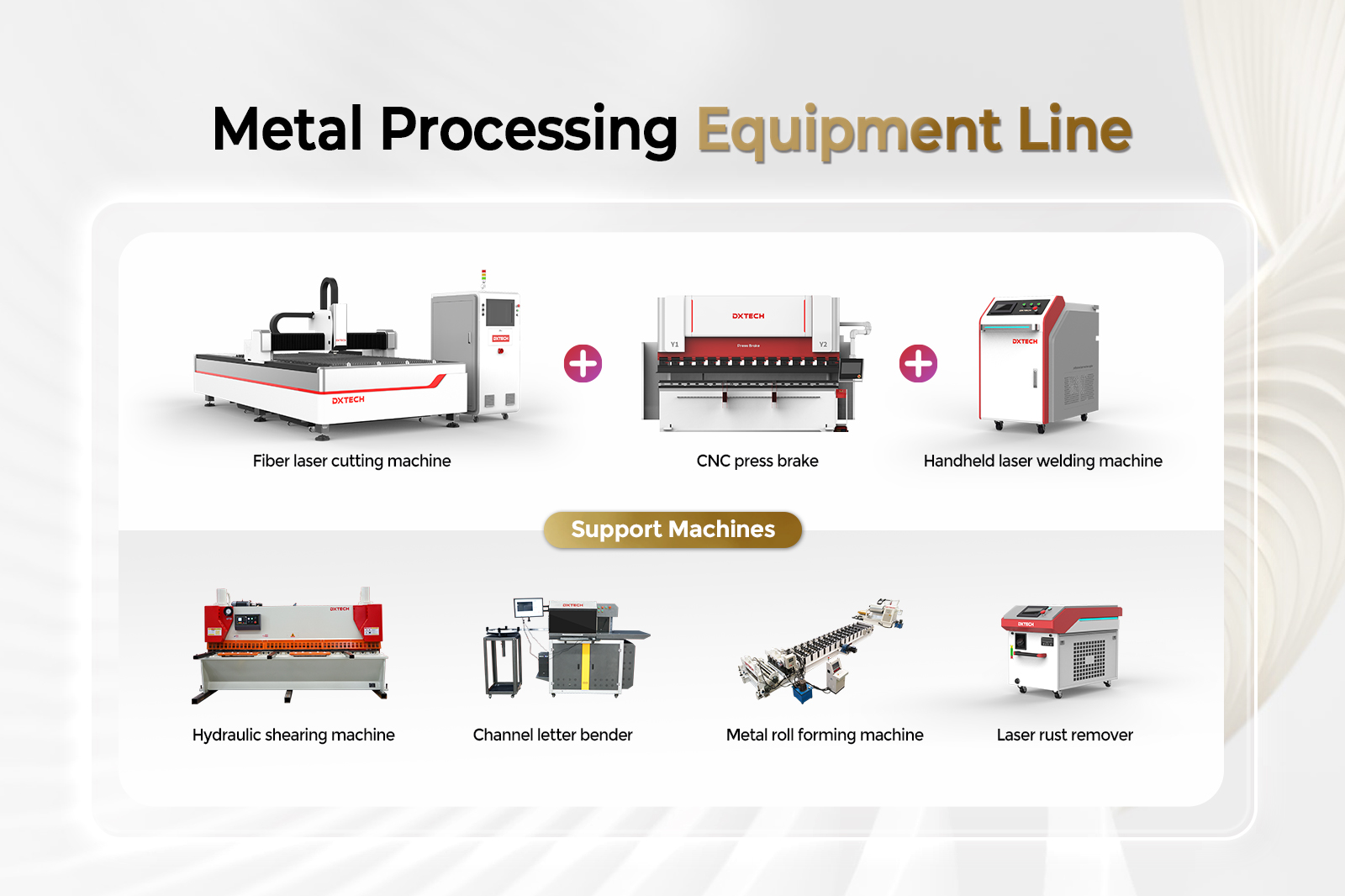

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.