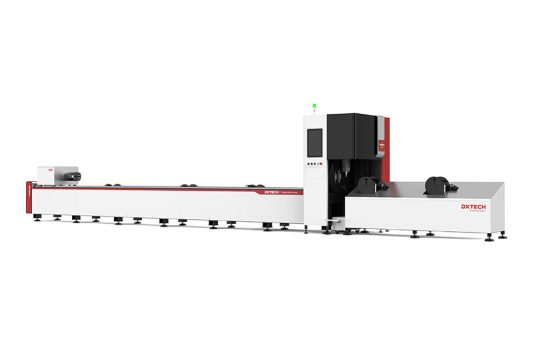

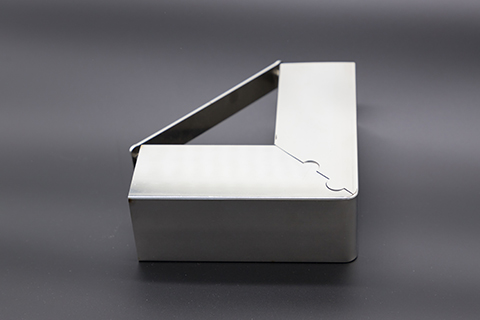

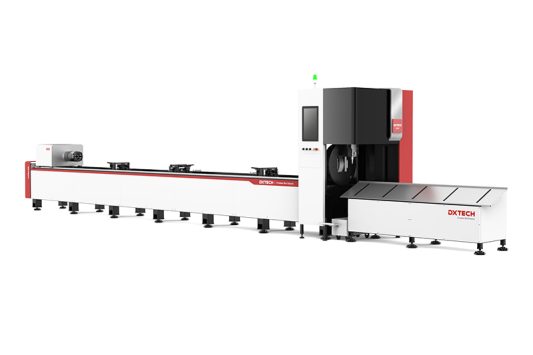

Suitable for a wide range of metal sheets and pipes, this Top 1500w Tube Laser Cutting Machine Factories CNC Laser Pipe Cutting Machine Manufacturers for Metal Tube Cutting is primarily applied to stainless steel, carbon steel, galvanized sheets, electrolytic plates, brass plates, aluminum plates, manganese steel, various alloy plates, and other materials, enabling rapid cutting of metals. It finds applications in diverse industries including sheet metal fabrication, automobile manufacturing, electrical cabinets, elevators and escalators, kitchen appliances, and metal doors and windows.

Video

Square Tube Laser Cutting Machine Advantages

-

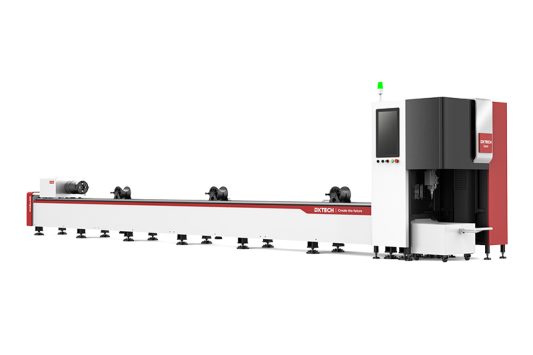

High-Rigidity Bed for Long-Term Stability

The machine is built with a high-rigidity bed, utilizing a unique high-temperature numerical control furnace annealing process. This ensures the long-term stability of the machine tool.

-

Superior Fiber Laser Quality

It comes equipped with an imported original packaged fiber laser that offers excellent beam quality and stable performance. The non-reflective lenses eliminate the need for optical path adjustments, making it virtually maintenance-free with a lifespan exceeding 100,000 hours.

-

High Electro-Optical Conversion Efficiency

The fiber laser boasts a high electro-optical conversion efficiency, reaching up to 30%. This significantly reduces power consumption during operation, resulting in extremely low operating costs.

-

Low Operating Costs and Fast ROI

With its high cutting speed, the machine ensures minimal operating costs and offers a rapid return on investment.

-

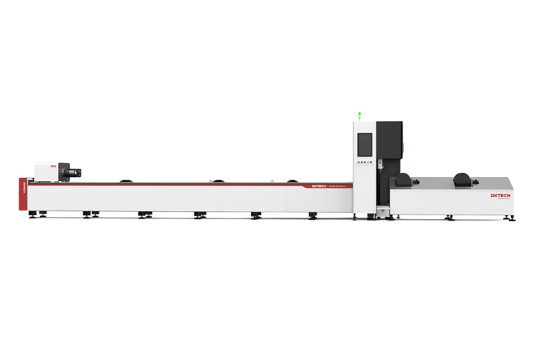

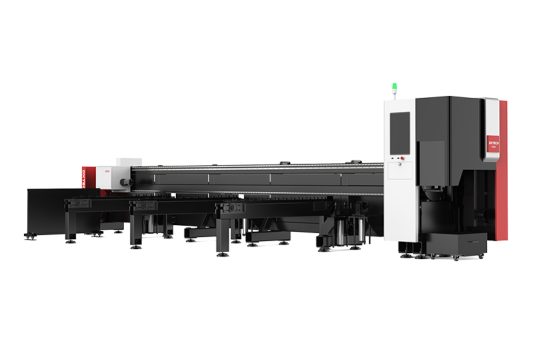

Advanced Material Handling

The machine features automatic screening of materials, powder handling, and an automatic turnover mechanism. These capabilities effectively prevent pipe sagging and enhance mechanical performance.

DXTECH Service

Business in person. Currently, we have a workshop covering an area of 45,000㎡ in Jinan, and we are constructing a new factory with an area of 30,000㎡ in Taian, Shandong Province.

From the moment you receive your laser machine, our sales team and factory technicians will handle all your after-sales issues together.

We offer free online training and technical support. Additionally, we can visit your location to assist with installation, debugging, training, and usage matters.

Components of Square Tube Laser Cutting Machine

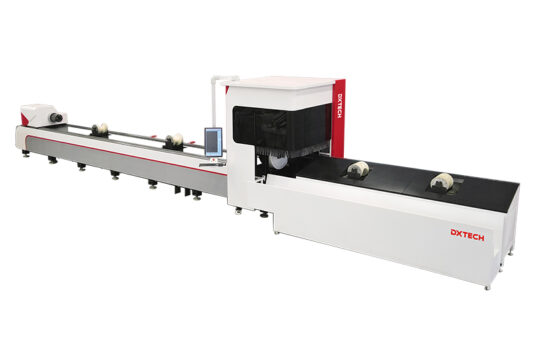

Intelligent focusing laser head

- Chasing Aperture: Utilizing a 35 mm aperture to effectively minimize the interference of stray light.

- Autofocus: Achieves a focusing speed of up to 10m/min without manual intervention, with a repeatability accuracy of approximately 50 microns.

TubePro tube cutting software

- This is a professional tube cutting system that ensures cutting accuracy by automatically centering and compensating for eccentricity in metal pipes.

- Common edge cutting helps minimize residual material, effectively reducing production costs.

- The corner cutting process ensures that corners are not burnt, maintaining high-quality sections.

Feedback from Customers All Over The World

We offer a free proofing service. Feel free to reach out for more information.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.