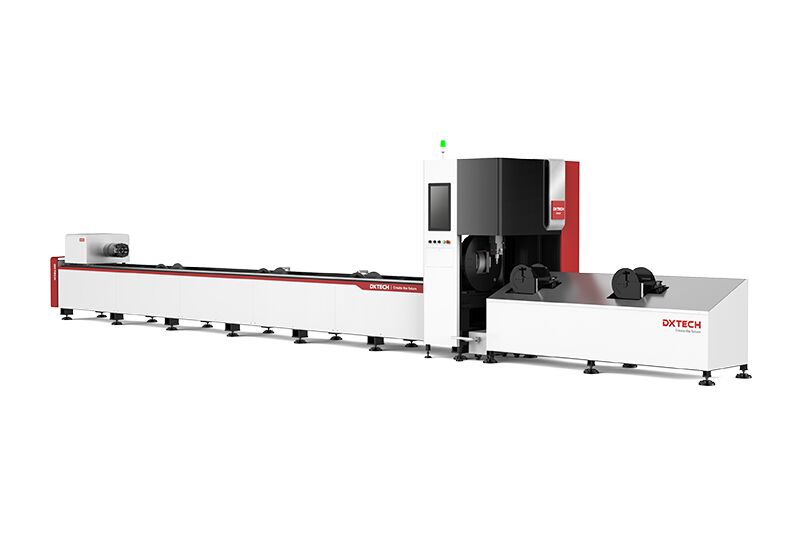

The High Capacity Square Tube Laser Cutting Machine for Carbon Stainless Steel Pipe Cutting can process various types of metal tubes, including round, square, and shaped tubes. It handles metal tubes with high precision and efficiency, capable of tasks such as cutting holes, chamfering, grooving, vertical cutting, and more. This machine is widely used in applications like automobile exhaust pipes, water pipes, oil pipes, fitness equipment, medical beds, bicycle racks, electric bicycle racks, baby carriages, kitchen storage racks, kitchen utensils, and more.

Video

Square Tube Laser Cutting Machine Advantages

-

One-Piece Welded Bed Design: Ensures high strength and rigidity, capable of withstanding large loads and impacts.

-

Precision Pneumatic Chuck: Stable and reliable with a one-key automatic unclamping structure, it can clamp various types of pipes, including square, round, oval, rectangular, channel steel, angle steel, and I-beam.

-

Advanced Fiber Laser Cutting Technology: Outputs a high-energy density laser beam for narrow slits and high-precision cutting.

-

Configured with Three Sets of Followers: Supports the pipe structure and automatically adjusts cutting speed, processing thickness, angle, and other parameters according to different conditions, achieving fine and high-precision cutting, especially suitable for large quantities of pipe processing.

-

Equipped with Intelligent CNC Control System: Featuring tube nesting software TubesT, it enables automatic layout cutting, common edge cutting, and efficient drop material handling, enhancing processing efficiency and saving time and material.

-

Optional Automatic Loading Device: Reduces labor intensity, allowing for easy, safe, and convenient whole pipe loading operations, effectively saving labor costs.

DXTECH Service

Business in person. Currently, we have a workshop covering an area of 45,000㎡ in Jinan, and we are constructing a new factory with an area of 30,000㎡ in Taian, Shandong Province.

From the moment you receive your laser machine, our sales team and factory technicians will handle all your after-sales issues together.

We offer free online training and technical support. Additionally, we can visit your location to assist with installation, debugging, training, and usage matters.

Components of Square Tube Laser Cutting Machine

Intelligent focusing laser head

-

Chasing Aperture: Utilizing a 35 mm aperture to effectively minimize the interference of stray light.

-

Autofocus: Achieves a focusing speed of up to 10m/min without manual intervention, with a repeatability accuracy of approximately 50 microns.

TubePro tube cutting software

-

This is a professional tube cutting system that ensures cutting accuracy by automatically centering and compensating for eccentricity in metal pipes.

-

Common edge cutting helps minimize residual material, effectively reducing production costs.

-

The corner cutting process ensures that corners are not burnt, maintaining high-quality sections.

Feedback from Customers All Over The World

We offer a free proofing service. Feel free to reach out for more information.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.