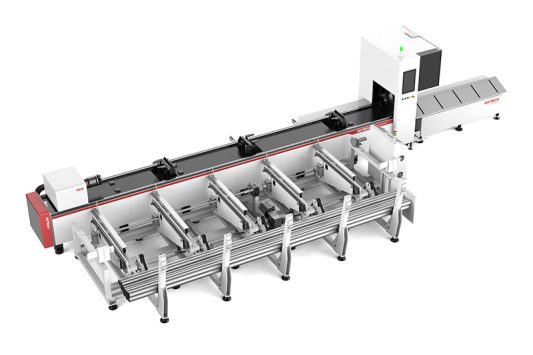

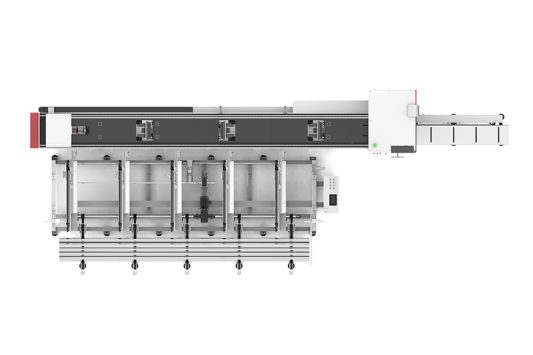

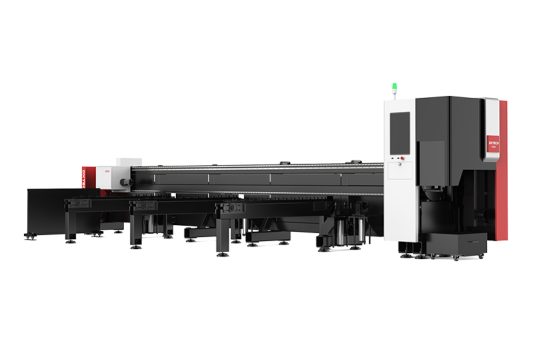

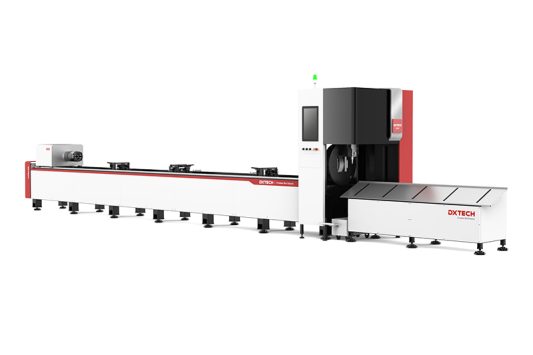

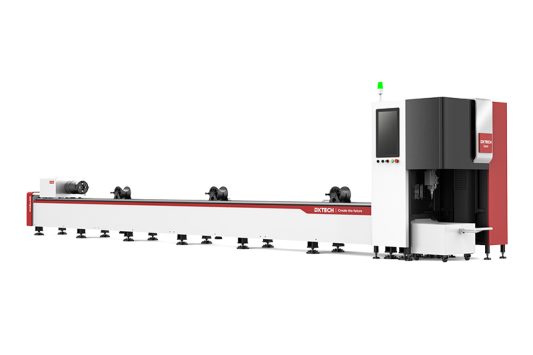

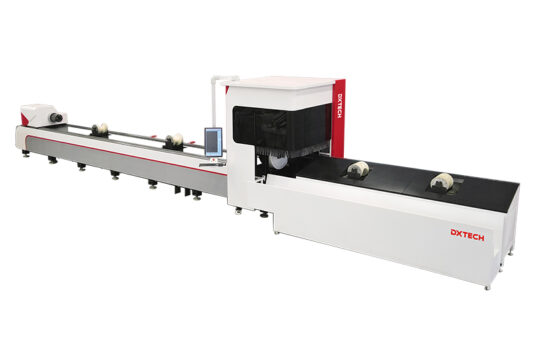

Wholesale Fiber Laser Tube Cutting Machine Applications

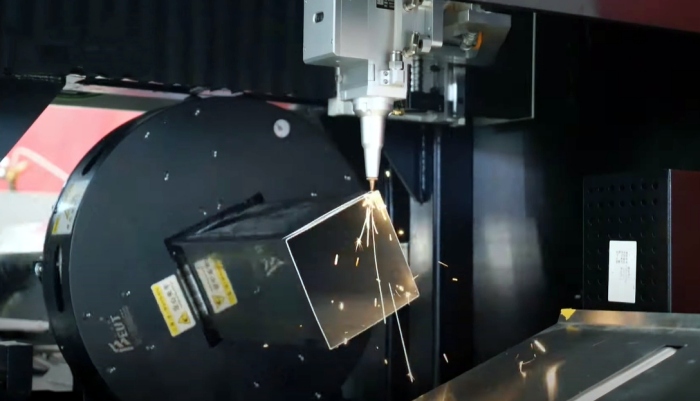

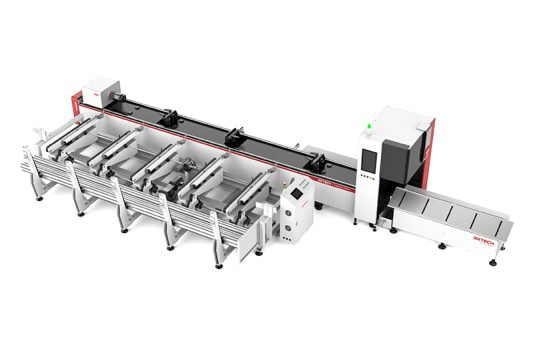

Fiber laser tube cutting machines which are wholesaled can be used to process square tubes, round tubes, elliptical tubes, irregular-shaped tubes, I-beams, channel beams, angle beams, and other metal tubular materials. Fiber laser sources can process a variety of materials, including stainless steel, carbon steel, and aluminum. The machines are widely used in industries such as advertising and decoration, exhibition stand frames, metal dining chairs, mechanical equipment, automobile manufacturing, hardware processing, sanitary ware manufacturing, elevator industry, home appliance manufacturing, storage racks, fitness equipment, steel structures, and construction machinery.

Wholesale Fiber Laser Tube Cutting Machine Specifications

| Model | TK6220/TK9220 | TK62406220/TK9240 | TK6300/TK9300 | TK6360/TK9360 |

| Max. tube length | 6.5/9.2m | 6.5/9.2m | 6.5/9.2m | 6.5/9.2m |

| Tube shape | Round/square/rectangular | Round/square/rectangular | Round/square/rectangular | Round/square/rectangular |

| Max. tube weight | 100kg 16kg/m | 200kg 30kg/m | 200kg 30kg/m | 500kg 83kg/m |

| Positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Chuck | Three pneumatic chucks | Three pneumatic chucks | Three pneumatic chucks | Three pneumatic chucks |

| Max. chuck rotating speed | 130r/min | 130r/min | 130r/min | 130r/min |

| Laser power | 1kW – 4kW | 1kW – 4kW | 1kW – 4kW | 1kW – 4kW |

| Laser | Multiple options | Multiple options | Multiple options | Multiple options |

| Clamping range | Φ20-Φ220mm □20 – □150mm |

Φ20-Φ240mm □20 – □150mm |

Φ20-Φ240mm □20 – □150mm |

Φ20-Φ360mm □20 – □150mm |

Wholesale Fiber Laser Tube Cutting Machine Advantages

1. Multi-functional integrated processing

Integrated punching, cutting, bevel cutting, and arc cutting functions reduce process turnover and directly improve production efficiency.

2. Fully Automatic Labor-Saving Operation

Supports fully automatic loading and unloading, allowing a single operator to manage multiple machines simultaneously, significantly reducing labor costs.

3. Efficient Dust Removal and Clean Operation

Equipped with dust covers, chucks, and built-in exhaust systems to achieve efficient dust removal and maintain a clean working environment.

4. Durable and Stable Machine Body

Features a high-strength cage-welded bed structure with strong deformation resistance, ensuring a machine tool lifespan of over 10 years.

DXTECH Service

Business in person. Currently, we have a workshop covering an area of 45,000㎡ in Jinan, and we are constructing a new factory with an area of 30,000㎡ in Taian, Shandong Province.

From the moment you receive your laser machine, our sales team and factory technicians will handle all your after-sales issues together.

We offer free online training and technical support. Additionally, we can visit your location to assist with installation, debugging, training, and usage matters.

Components of Wholesale Fiber Laser Tube Cutting Machine

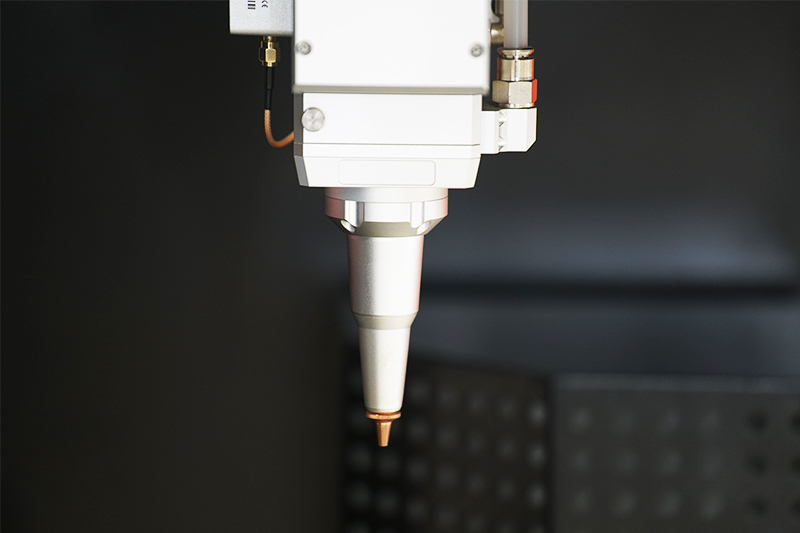

Intelligent focusing laser head

1. Stray Light Minimization with Special Aperture :

A 35 – mm aperture effectively reduces stray – light interference.

2. High – Speed and Precise Autofocus Feature

Autofocus reaches 10m/min without manual input, with ±50 – micron repeatability.

TubePro tube cutting software

- This is a professional tube cutting system that ensures cutting accuracy by automatically centering and compensating for eccentricity in metal pipes.

- Common edge cutting helps minimize residual material, effectively reducing production costs.

- The corner cutting process ensures that corners are not burnt, maintaining high-quality sections.

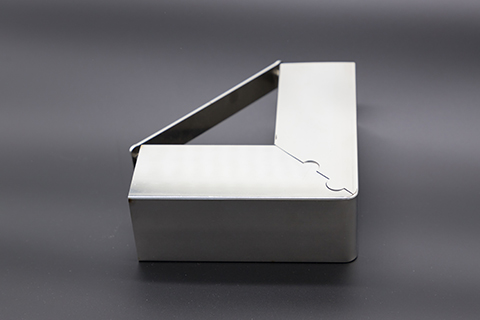

Wholesale Fiber Laser Tube Cutting Machine Samples

We offer a free proofing service. Feel free to reach out for more information.

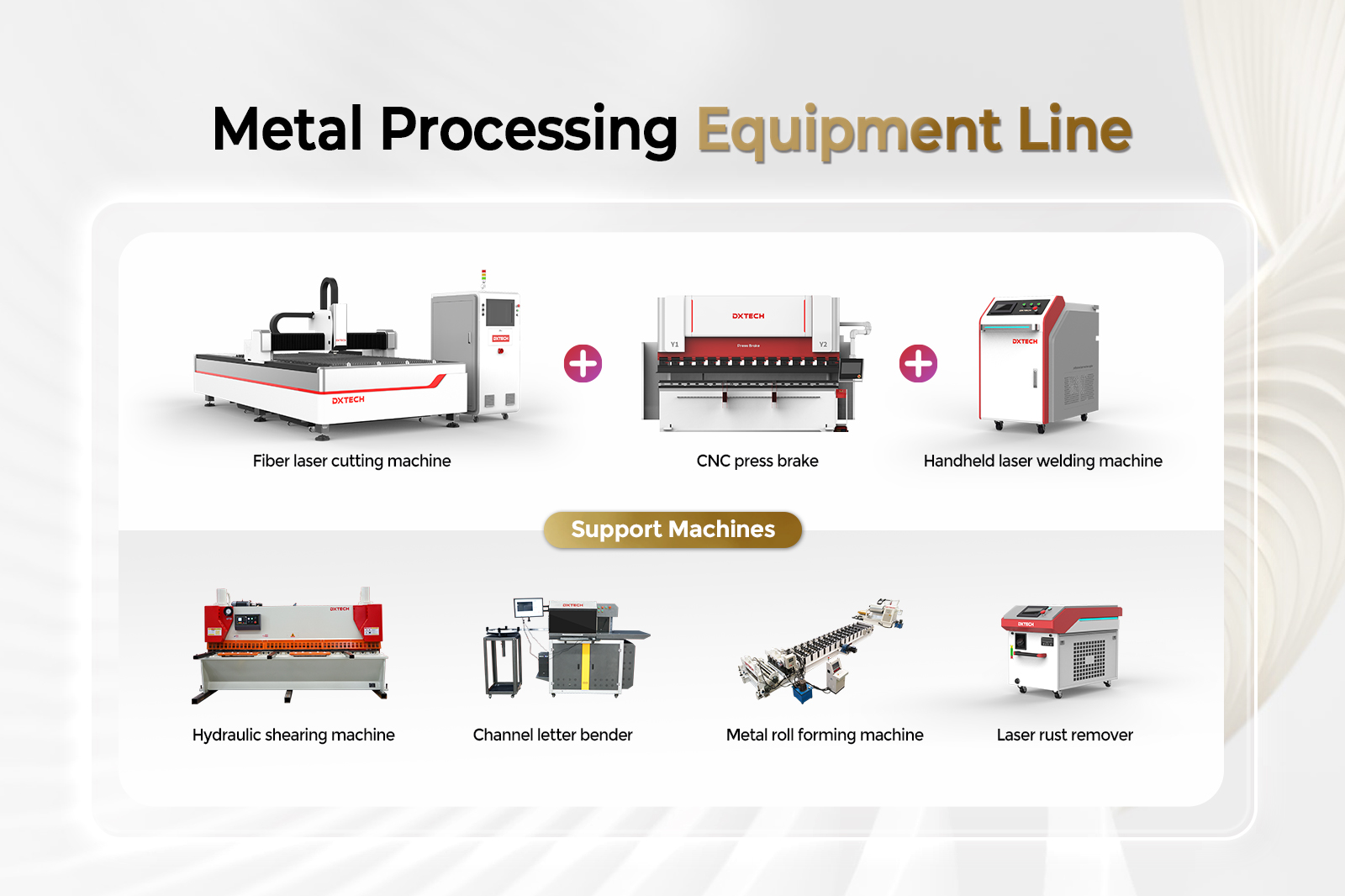

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.