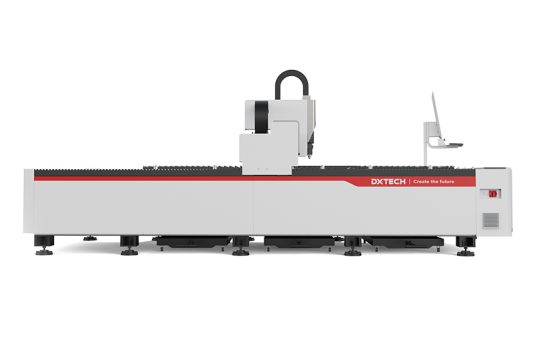

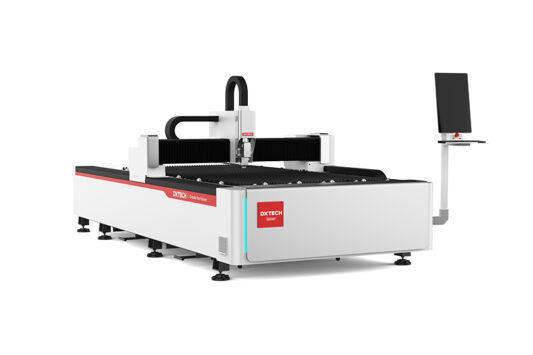

┃ Open Type Fiber Laser Cutting Machine Applications

Open-type fiber laser cutting machines are widely utilized for processing a range of metal materials such as carbon steel, alloy structural steel, stainless steel, and copper. They deliver precise, high-speed cutting and welding of thin sheets, while also handling sawing and punching tasks for medium-thick plates. These machines are extensively employed in metal fabrication, automotive production, mechanical component manufacturing, and hardware parts processing.

┃Open Type Fiber Laser Cutting Machine Advantages

✅ 1. Reinforced Gantry Framework for Superior Stability

Featuring an integrated cast aluminum crossbeam, the gantry structure boosts stability and shock resistance by 100%.

✅ 2. Smart Collision Prevention for Longevity

A 360° intelligent anti-impact system safeguards efficient operation while prolonging the machine’s service life.

✅ 3. Adaptive Laser Head for Precise Cuts

The auto-focus laser head adjusts to different metal thicknesses, guaranteeing accurate cutting results.

✅ 4. Wireless CNC Control for Effortless Operation

Paired with cutting-edge CNC software, the wireless handheld controller enables intuitive, hassle-free operation.

✅ 5. 70% Faster Carbon Steel Processing

Significantly accelerated cutting performance reduces piercing time for <20mm carbon steel by 70%.

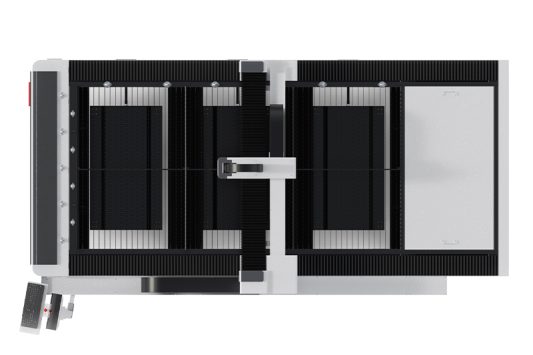

┃Open Type Fiber Laser Cutting Machine Specifications

| Model | 1530FP | 2060FP | 2560FP |

| Working area | 1515*3030 | 6000mm×2000 | 2520*6050 |

| Worktable bearing capacity | 800kg | 1800kg | 2200kg |

| Positioning Accuracy | ±0.03mm | ||

| Repositioning accuracy | ±0.02mm | ||

| Max. acceleration | 1.2G | ||

| Laser power | 1-6kw | ||

| Laser | Multiple options | ||

| Machine bed | Sheet welded bed | ||

| Max Running Speed | 140m/min | ||

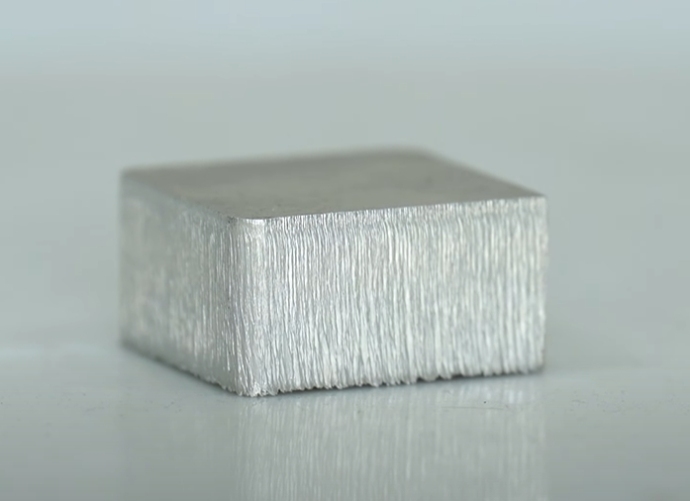

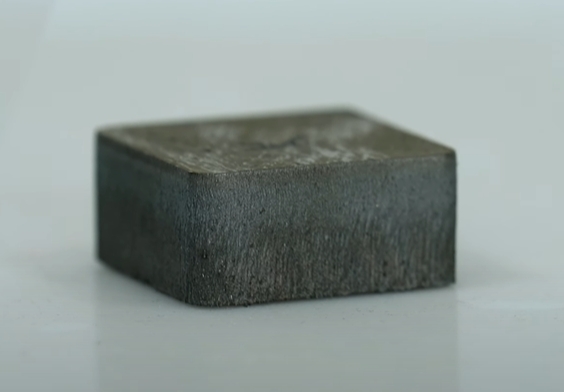

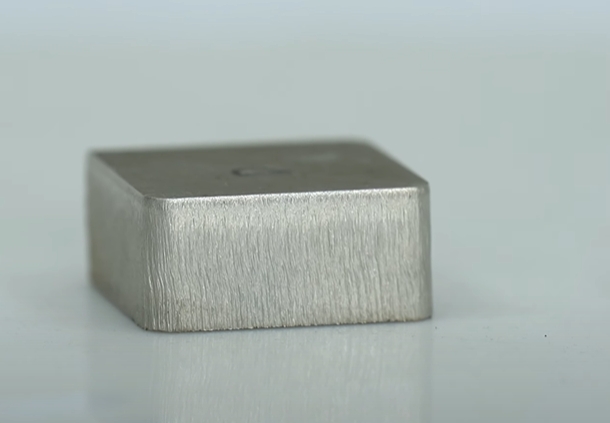

┃ Open Type Fiber Laser Cutting Machine Samples

We provide free proofing service. Welcome to consult.

┃ DXTECH Services

DXTECH operates three major production facilities covering 75,000 m². With over 50 national patents and international certifications (ISO, FDA, UL, CE), its products are exported to 180+ countries. The company has sales networks in 20+ nations (e.g., US, Spain, Bosnia, Australia) and local offices in Bosnia, Spain, and Turkey for on-site installation, training, and support.

Founded in 2009, DXTECH has a full-value chain system spanning R&D, production, sales, and after-sales. Services include free online training and dispatch of specialists for on-site equipment installation, commissioning, and operational guidance.

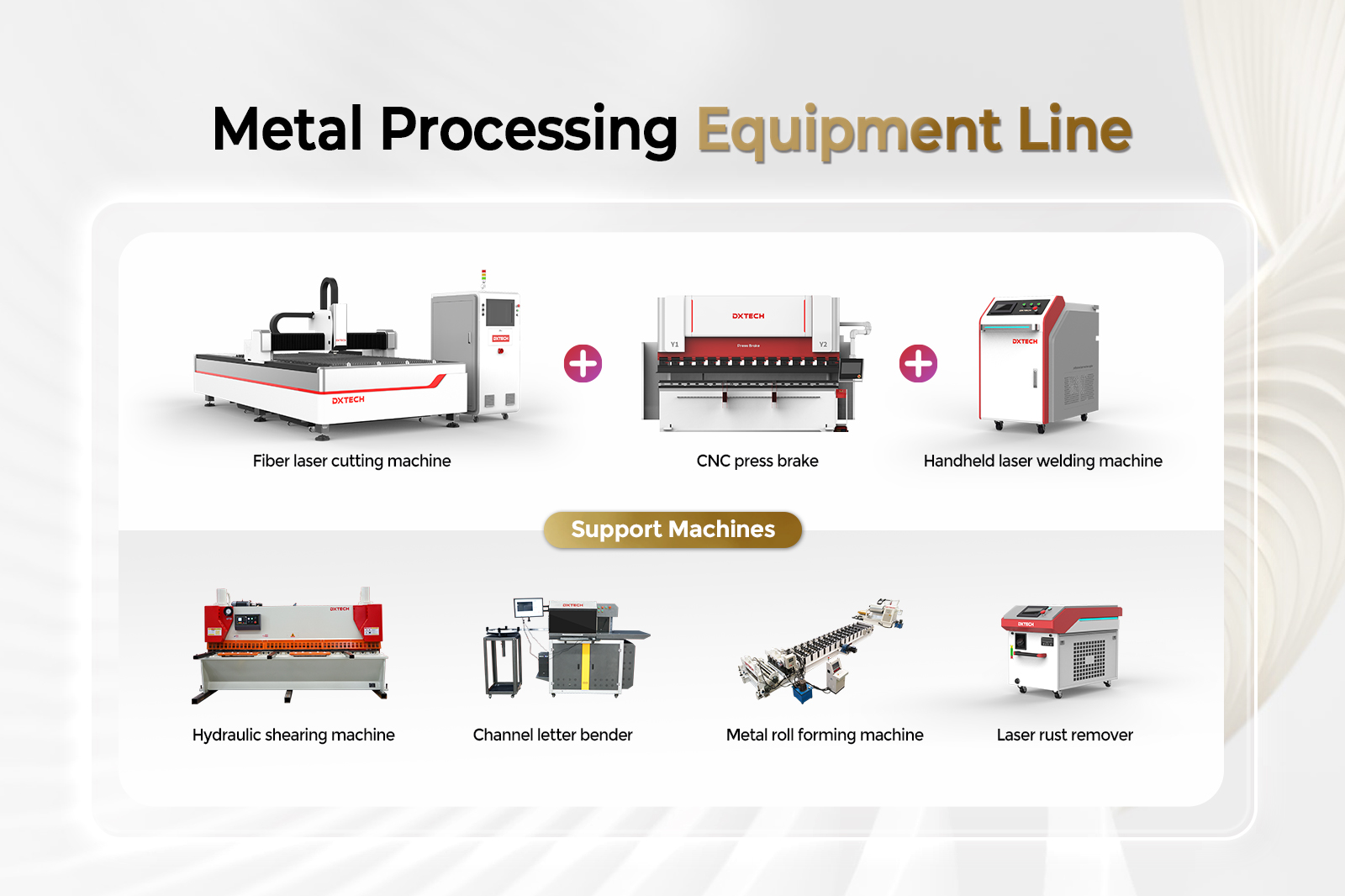

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.