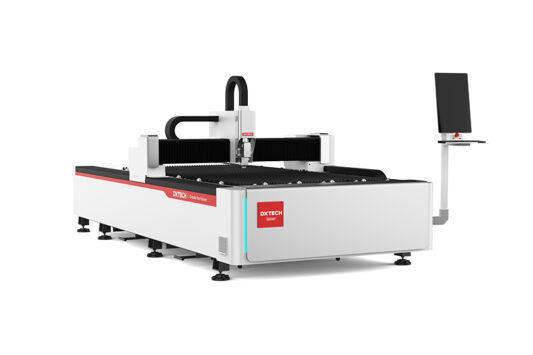

┃ 10mm Metal Laser Cutting Machine Applications

10mm metal laser cutting machine can be used for cutting and processing metal materials thicker than 10 mm, such as stainless steel, carbon steel, aluminum, and iron. The 10mm metal steel laser cutting machines are widely used in sheet metal processing, automobile manufacturing, construction machinery, mechanical manufacturing, elevators, home appliances, tool processing, advertising and decoration, metal processing, kitchenware processing, and various other manufacturing and processing industries.

┃10mm Metal Laser Cutting Machine Advantages

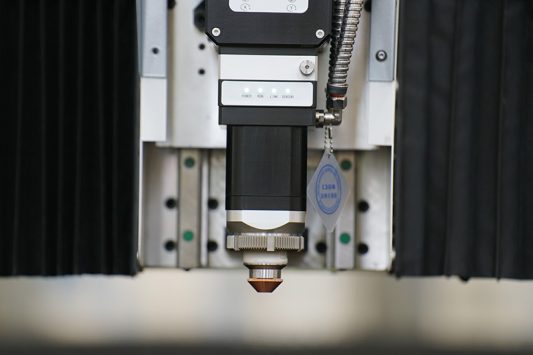

1. Auto-Adjusting Laser Head

Automatically adapts to varying metal thicknesses, with 360° intelligent collision protection for efficient, long-lasting cutting.

2. Smart Cutting System

Dynamic adjustments boost speed by over 60% vs. traditional systems, with simpler calibration.

3. Wireless Handheld Controller

Seamlessly integrates with the latest CNC software and hardware—user-friendly and highly responsive.

4. 11-Point Quick Lubrication

Doubles lubrication efficiency compared to 8-point systems, enabling more precise cutting.

┃10mm Metal Laser Cutting Machine Specifications

| Model | 1530FP | 1560FP | 2560FP |

| Working area | 1515*3030 | 1515*6050 | 2520*6050 |

| Worktable bearing capacity | 800kg | 1300kg | 2200kg |

| Positioning Accuracy | ±0.03mm | ||

| Repositioning accuracy | ±0.02mm | ||

| Max. exchange time | 25s | 35s | 40s |

| Max. acceleration | 1.2G | ||

| Laser power | 12kw | ||

| Laser | Multiple options | ||

| Machine bed | Sheet welded bed | ||

| Max Running Speed | 140m/min | ||

┃ 10mm Metal Laser Cutting Machine Samples

We provide free proofing service. Welcome to consult.

┃ DXTECH Services

DXTECH extends a warm invitation to both domestic and international customers to visit our factories and offices for in-person business discussions. Currently, we have a workshop spanning 45,000㎡ in Jinan and are constructing a new factory covering 30,000㎡ in Taian, Shandong Province.

From the moment you receive your laser machine, our dedicated sales team and factory technicians will handle all your after-sales concerns.

We offer complimentary online training and technical support. Additionally, we can visit your location to manage the installation, debugging, training, and usage processes.

Laser Machine Upgrade

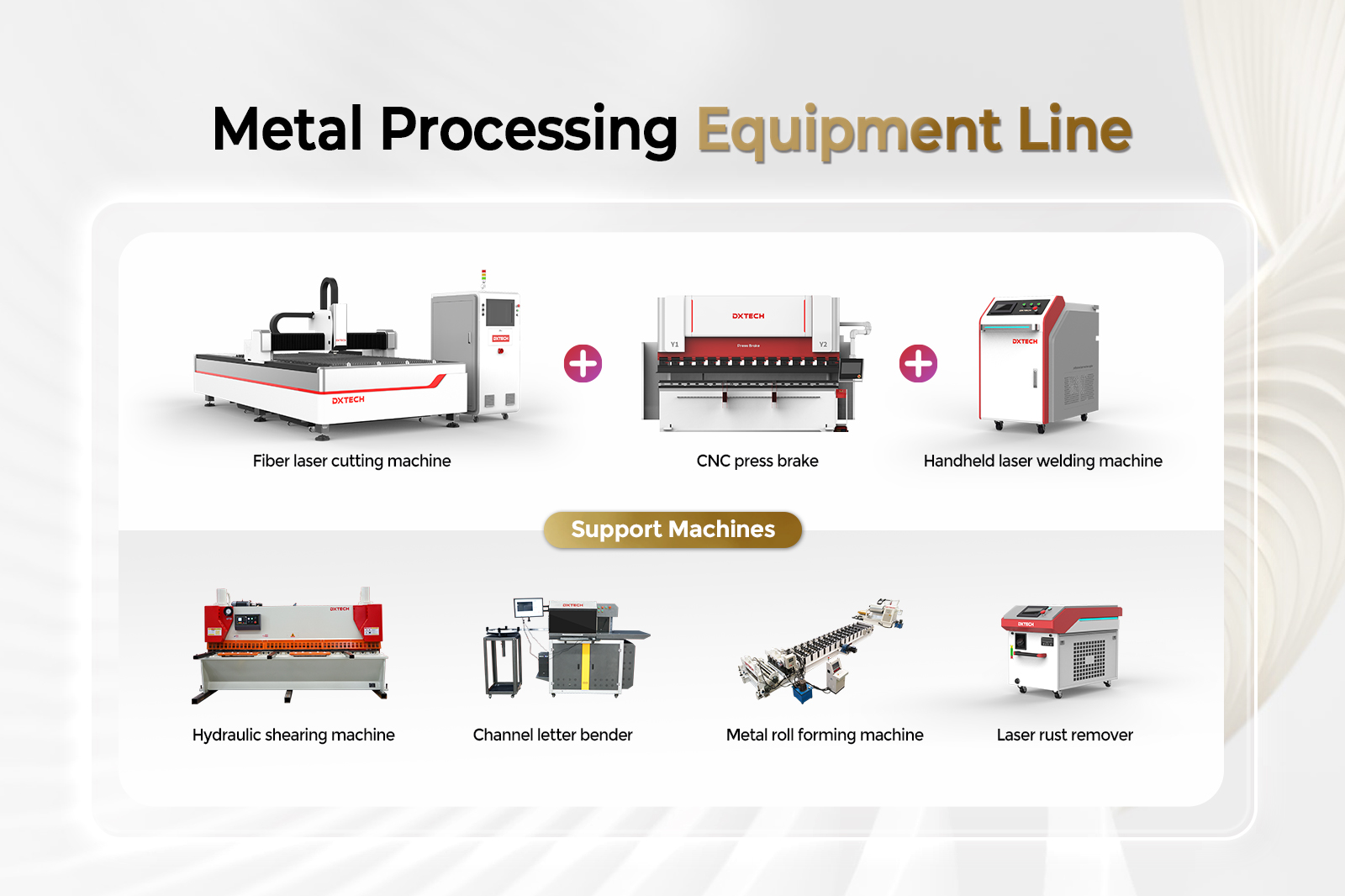

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.