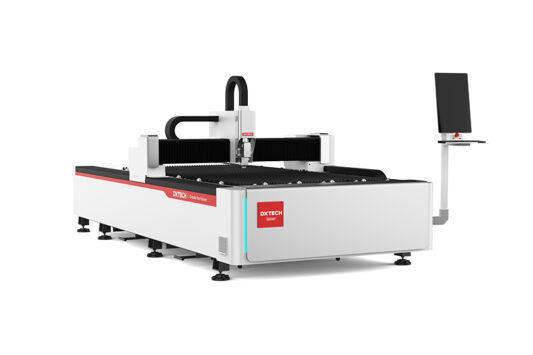

┃ Steel Laser Cutting Machine for Sheet Tube Applications

The laser cutting machine is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, aluminum-zinc plated sheet, copper, and other metal materials. It is widely used in sheet metal processing, automobile manufacturing, furniture, and home appliance industries.

┃Steel Laser Cutting Machine for Sheet Tube Advantages

1. Ultra-Fast Piercing Technology

The fully-automatic focusing laser cutting head slashes piercing time by up to 70% compared to conventional heads, enabling rapid cutting of thick plates (up to 25mm) at industry-leading speeds.

2. Pneumatic Self-Centering Chuck

Featuring dual-action symmetrical clamping, this intelligent chuck eliminates manual adjustments. It ensures precise alignment and secure holding of tubes/plates, streamlining setup for uninterrupted production.

3. Universal Cutting Compatibility

Our proprietary laser system seamlessly processes both flat sheets and complex tubular profiles. With automatic parameter adjustment, it delivers consistent precision across diverse materials and geometries.

4. Safety-Optimized Design

The semi-enclosed protective casing combines operator safety with clear process visibility. Its ergonomic design allows real-time monitoring while fully complying with CE safety standards.

┃Steel Laser Cutting Machine for Sheet Tube Specifications

| Model | DXTECH-1530SLT | DXTECH-2040SLT | DXTECH-2560SLT |

| Working area (mm) | 1515*3030 | 2020*4040 | 2525*6050 |

| Positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm | ±0.02mm |

| Max. exchange time | 25s | 30s | 40s |

| Max. acceleration | 2.0G | 2.0G | 2.0G |

| Laser power | 1kW – 3kW | 1kW – 3kW | 1kW – 3kW |

| Laser | Multiple options | Multiple options | Multiple options |

| Focusing method | Auto/manual | Auto/manual | Auto/manual |

| Machine bed | Sheet welded bed | Sheet welded bed | Tube welded bed |

| Max. running speed | 140m/min | 140m/min | 140m/min |

┃ DXTECH Services

DXTECH extends a warm invitation to both domestic and international customers to visit our factories and offices for in-person business discussions. Currently, we have a workshop spanning 45,000㎡ in Jinan and are constructing a new factory covering 30,000㎡ in Taian, Shandong Province.

From the moment you receive your laser machine, our dedicated sales team and factory technicians will handle all your after-sales concerns.

We offer complimentary online training and technical support. Additionally, we can visit your location to manage the installation, debugging, training, and usage processes.

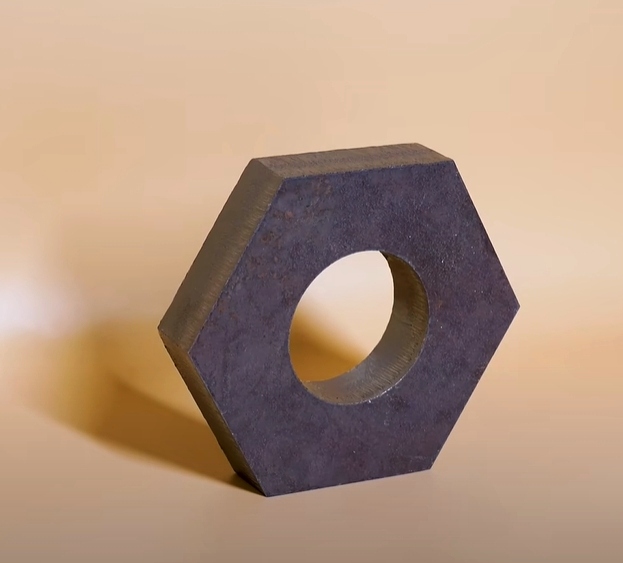

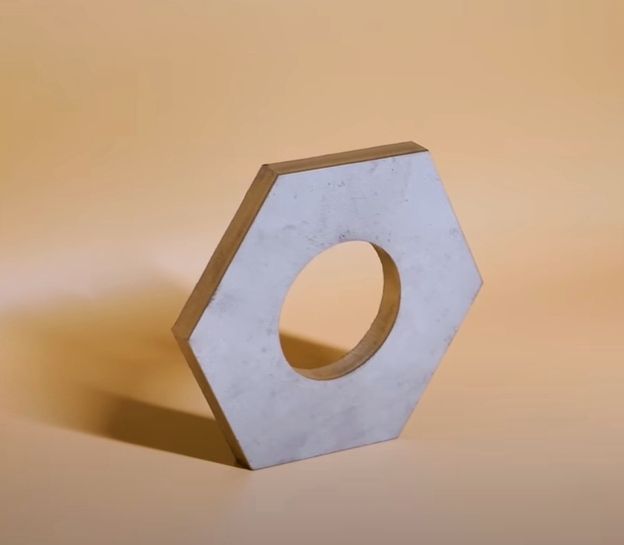

┃ Steel Laser Cutting Machine for Sheet Tube Samples

We provide free proofing service. Welcome to consult.

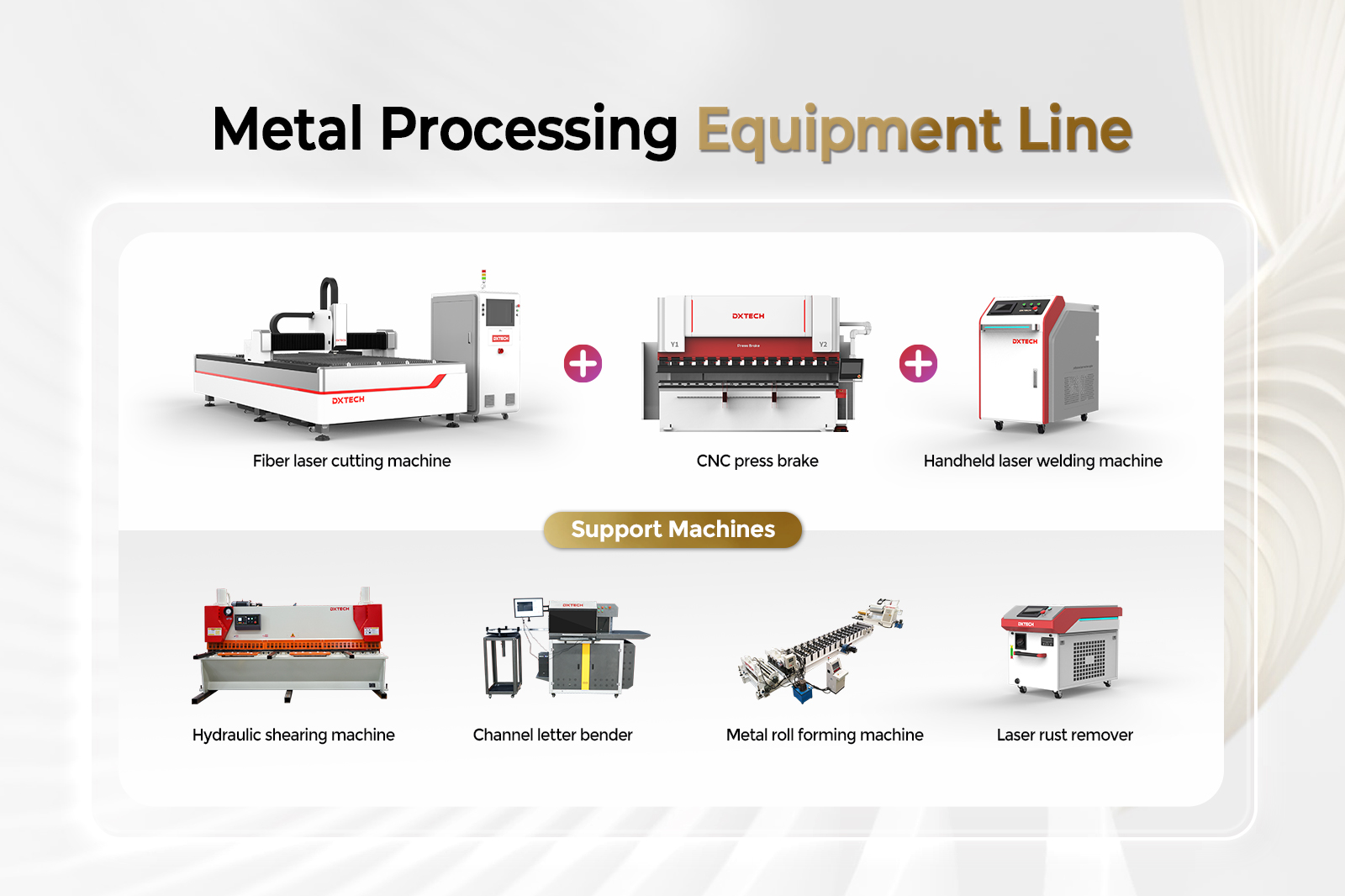

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

Reviews

There are no reviews yet.