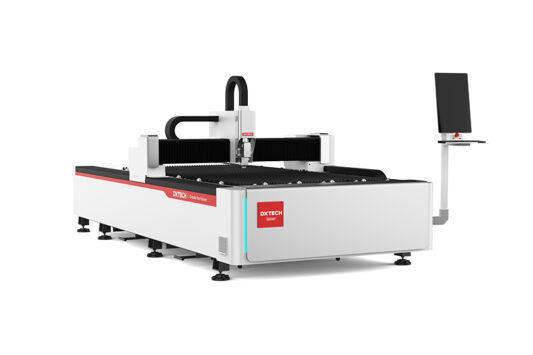

FL- 3kw laser cutting machine is a commonly used economical fiber laser cutting machine for metal mainly suitable for the advertising industry. The control cabinet of the machine is placed inside the machine, which saves space and is suitable for many small and medium-sized enterprises.

3kw Laser Cutting Machine Advantages

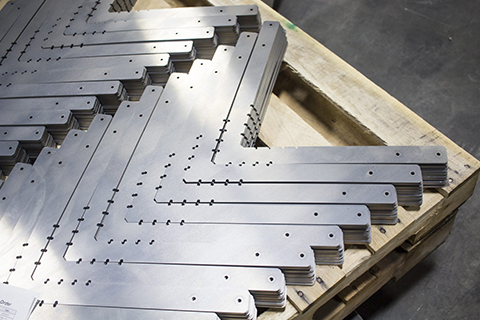

1. High-rigidity Welding Machine Bed

The 3kw laser cutting machine bed is processed with a stress relief annealing method, which ensures its strong strength, and is not easy to deform. The max load of platform is 1000KG, stable and reliable in a variety of working scenarios.

2. Optimized Exhausting System

The new generation introduces German technology and the air outlet is designed to be large in front while small in the back, which ensures consistent ventilation effects and significantly improves the performance of the ventilation system.

3. Assembled Delivery

Well-designed and can be put directly into the container without disassembling any parts. Upon being powered on, it runs immediately. This design significantly shortens the customer’s installation and debugging time and greatly facilitates the customer’s use experience.

4. All-round Smart Automatic Lubrication

Compared to the cutters equipped with 8 point lubrication system. It improves the service life of the equipment by up to 20%.

5. Material Collecting Trolley

The DXTECH trolley has an innovative design and adopts German corrugated technology, improving load-bearing and deformation resistance and significantly extending service life.

3kw Laser Cutting Machine Parameters

| Model | DX-1530FL(1-3KW) | DX-1530FL(6KW) |

| Machine size | 4616*2231*1950 | 4616*2231*1950 |

| Total weight of equipment | 1.6T | 2T |

| Processing area | 1550×3050 | 1550×3050 |

| Table load | 1000kg | 1000kg |

| Maximum linear speed | 60m/min | 100m/min |

| Maximum linkage speed | 85m/min | 140m/min |

| Maximum linear acceleration | 0.8G | 1G |

| Maximum linkage acceleration | 1.1G | 1.4G |

| Positioning accuracy | ±0.03 | ±0.03 |

| Repeat positioning accuracy | ±0.02 | ±0.02 |

| Focusing method | Auto | Auto |

DXTECH Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

DXTECH Quality Assurance

2 Years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Customer feedback

Components of Fiber Laser Cutting machine

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

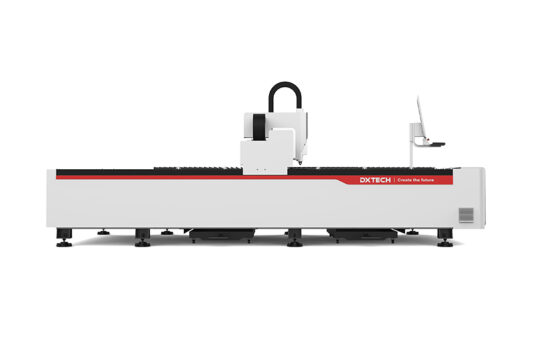

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

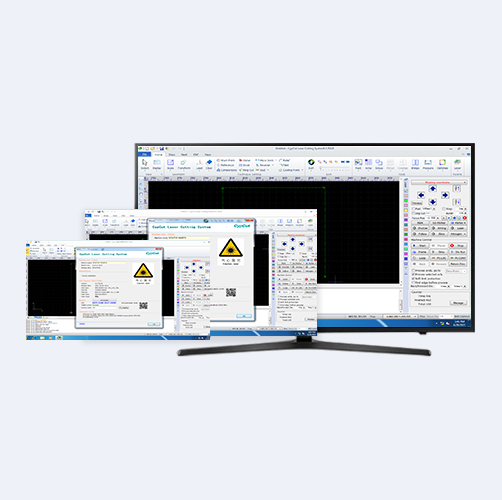

Weihong LS1500/LS3000 Laser Cutting Control System

Weihong laser cutting control system is a software for plane laser cutting. It supports AI, DXF, PLT and international standard G codes generated by Mater Cam, Type3, Wentai, etc.

Except common editing and typesetting functions, it has unique processing sequence browsing and powerful material database to load the specification directly. Besides, operators can control the system through wireless handheld box and Ethernet conveniently.

▐ Laser Machine FAQ

Of course. From laser configuration to automation systems, we provide tailor-made solutions to meet your specific needs.

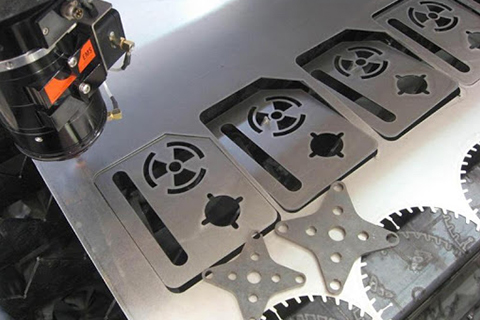

It can cut various metals including stainless steel, carbon steel, aluminum, brass, copper, galvanized steel, and alloys.

2-year warranty for the main machine, 1-year for laser source and key components—covers manufacturing defects, excluding wear parts.

Standard models: 7-15 days; custom models: 30-45 days (varies by configuration and shipping location).

Laser source: annual check; lenses and nozzles: clean/replace every 200-300 hours; guide rails: lubricate monthly.

Reviews

There are no reviews yet.