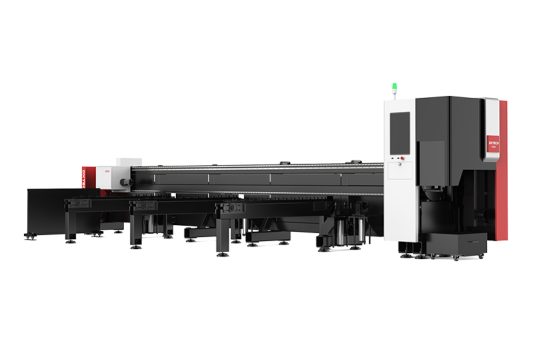

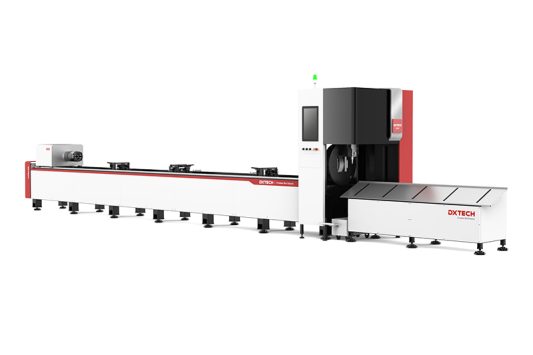

The Dual Use co2 metal laser cutting machine, available at appealing prices in Venezuela/VE and Colombia/CL, has an incredibly wide range of applications across numerous manufacturing and processing industries. In the household sector, it’s essential for crafting kitchenware with precision. For the lighting industry, it enables the creation of intricate lamp designs. In hardware cabinets and sheet metal processing, it provides high – quality cutting, enhancing product quality. In specialized fields like aerospace and automotive parts manufacturing, its precision is highly valued for fabricating components with tight tolerances. It streamlines production in appliance manufacturing for refrigerators, air conditioners, and elevators. In the hospitality industry, it’s used to make hotel metal supplies. In arts and crafts, it helps produce unique items, and in tool processing, it cuts tool materials accurately. It’s also a top choice in decorative advertising and metal external processing for creating attractive designs and high – quality metal products, making it an indispensable asset in various manufacturing and processing areas in Venezuela and Colombia.

CO2 Metal Laser Cutting Machine Video

CO2 Metal Laser Cutting Machine Advantages

1. Versatile Cutting for Cost – Efficiency

This laser cutting machine has the remarkable ability to cut both metal plates and non – metal profiles. With one machine serving multiple purposes, it eliminates the need to purchase two separate machines, saving not only the cost but also valuable space. Moreover, it significantly boosts productivity, making it a cost – effective and space – saving solution.

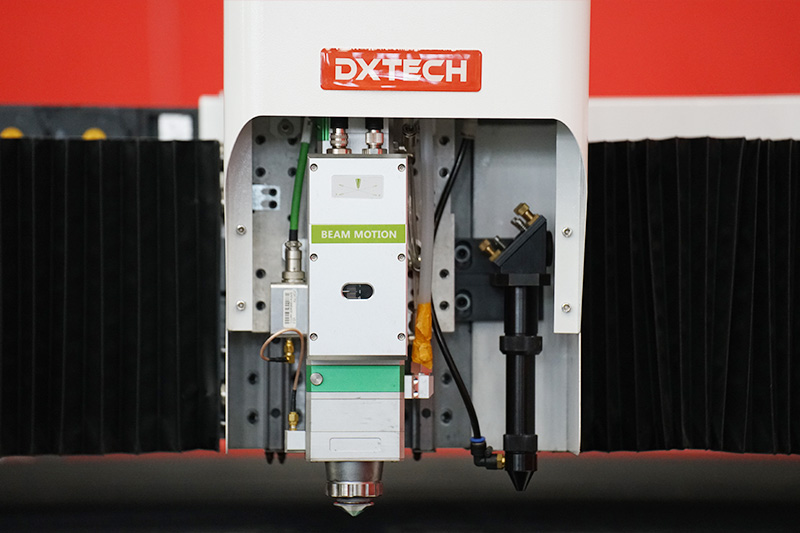

2. Automatic Adjustable Focusing for Varied Plate Thickness

Fitted with an automatic adjustable focusing mirror, this machine can precisely control the upper and lower height. This feature enables the perforation cutting of plates with different thicknesses. The adjustable range is ±10, and it offers a precision of 0.01mm, being suitable for plates with thicknesses ranging from 0 – 20mm.

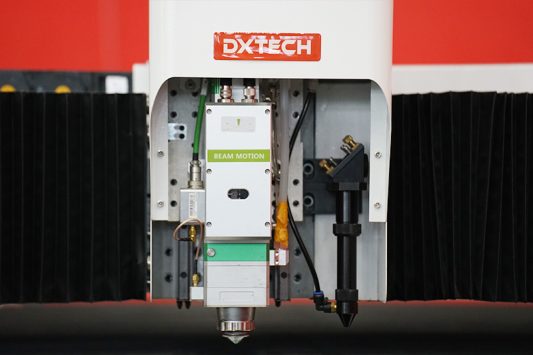

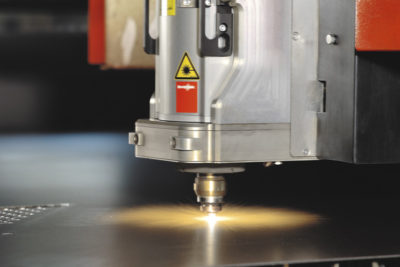

3. Superior Performance, Stability, and Precision

The machine boasts excellent performance, stability, and precision. It has been engineered to enhance stability substantially. By achieving higher speeds, it ensures high – precision and high – speed operation simultaneously, meeting the demands of various industrial applications.

4. Intelligent and User – Friendly CNC System

The intelligent CNC cutting system is extremely user – friendly. It is easy to learn and operate, and convenient for debugging. Packed with a wide range of cutting functions, these can be activated with just one key. This allows users to quickly get started and convert their skills into productivity in no time.

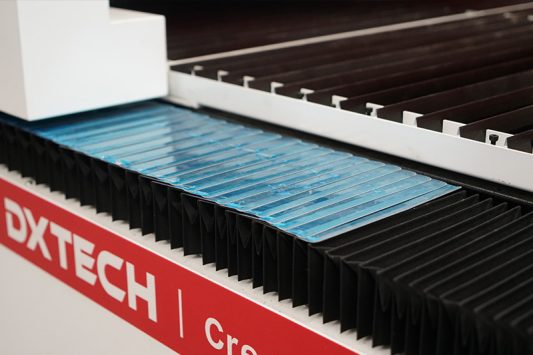

5. High – Quality Welding Bed with Longevity

Featuring a high – quality welding bed, the machine can achieve a positioning accuracy of up to 0.02mm. With a working life of over 10 years, it offers long – term reliability and durability for continuous use in industrial settings.

CO2 Metal Laser Cutting Machine Parameters

| Model | DXTECH-1325CF | DXTECH-1530CF |

| Working area | 1313*2525mm | 1515*3030mm |

| Positioning accuracy | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm |

| Max. acceleration | 1.5G | 1.5G |

| Fiber Laser power | 1kW – 2kW | 1kW – 2kW |

| Co2 Laser power | 75w-300w | 75w-300w |

| Laser | Multiple options | Multiple options |

| Focusing method | Auto/manual | Auto/manual |

| Max. running speed | 140m/min | 140m/min |

DXTECH Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

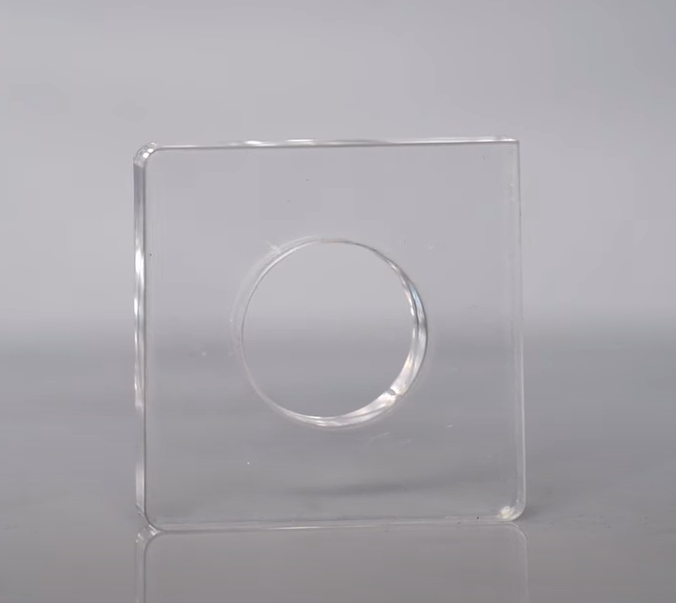

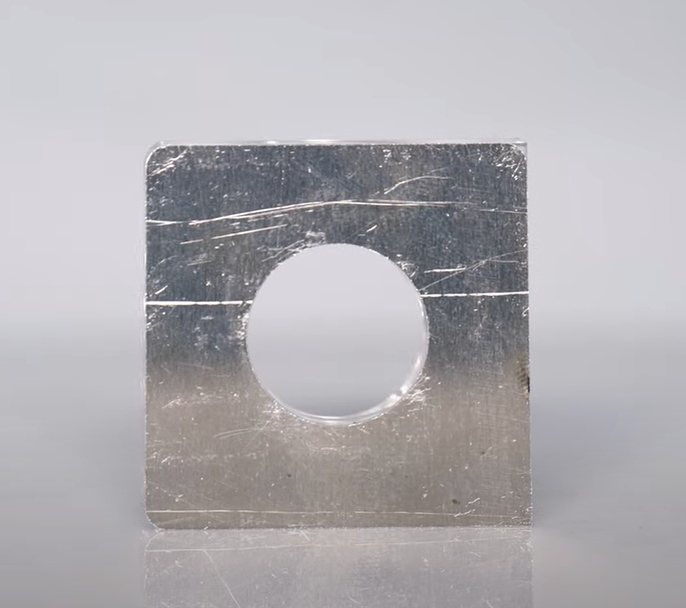

CO2 Metal Laser Cutting Machine Samples

We provide free proofing service. Welcome to consult.

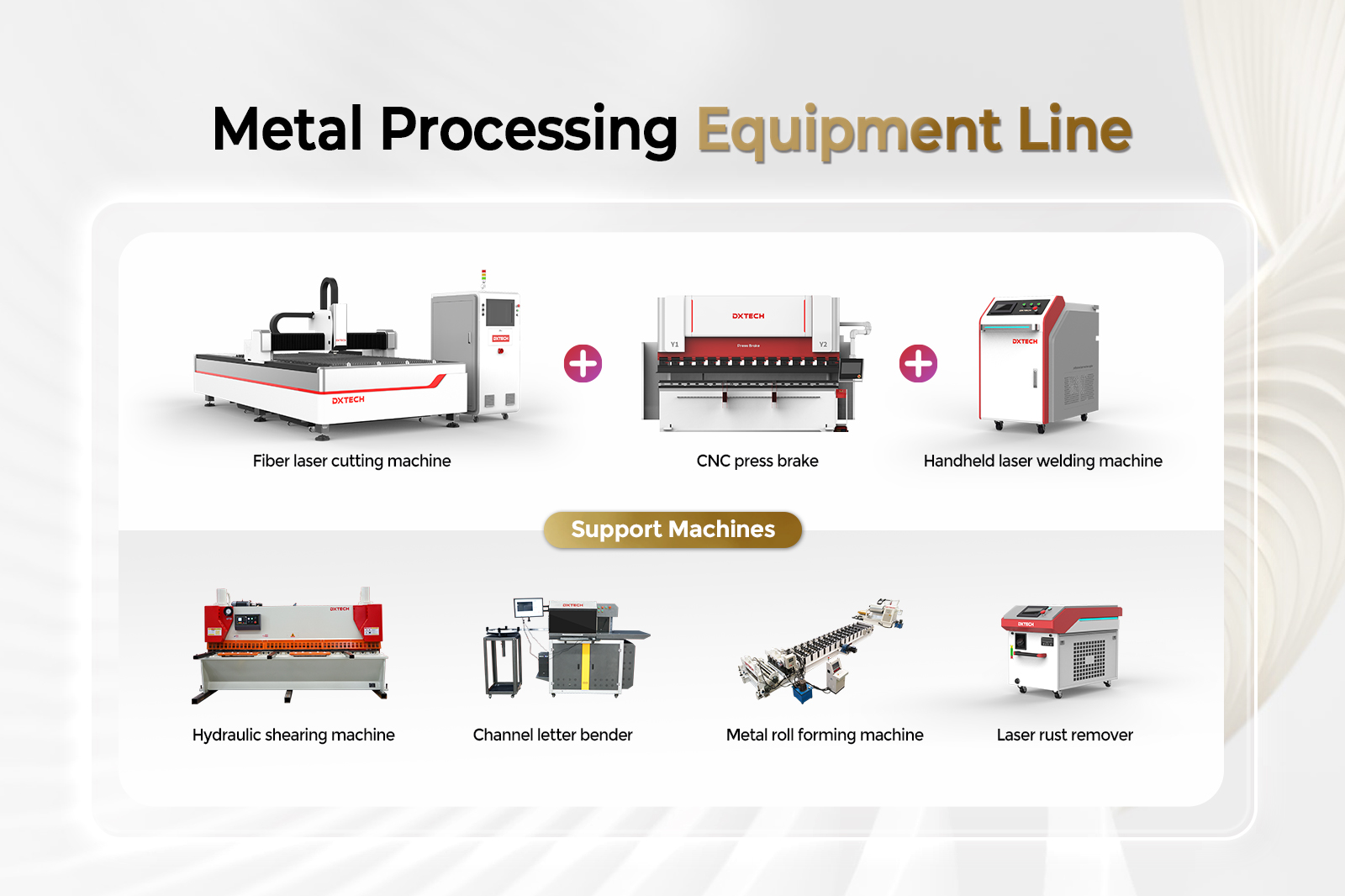

Laser Machine Upgrade

DXTECH is committed to providing one-stop processing solutions for your metal processing factory. We not only provide a complete production line of fiber laser cutting machine + CNC press brake + handheld laser welding machine, but also provide a series of auxiliary equipment, such as Hydraulic shearing machine, Channel letter bender, Metal roll forming machine and Laser rust remover, etc.

- One-stop processing

- More efficient production

Choosing DXTECH means you no longer have to worry about finding manufacturers of various machines and equipment. Our comprehensive services will ensure that your production process is efficient and smooth.

DXTECH focuses on providing customized equipment upgrade solutions for your metal processing plant. If your factory is still using traditional equipment such as plasma cutting machines, hydraulic shearing machines or water jet cutting machines that have low processing efficiency and unsatisfactory cutting quality, then DXTECH will be your ideal choice.

- More efficient

- More precise

- More energy-saving

We can help you upgrade these equipment to more efficient, more precise, and more energy-saving fiber laser cutting machines, thereby greatly improving processing efficiency and cutting quality, and bringing a qualitative leap to your factory.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.