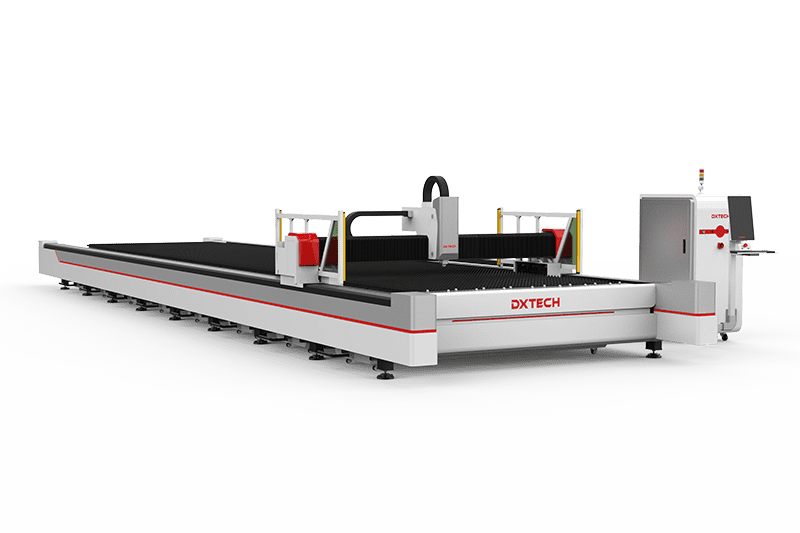

The Open Type Large Laser Cutting Machine High Power 12000w 10000w Laser Cutting Machine for Sheet Metal Laser Cutting presents numerous advantages, including exceptional precision and minimal heat impact during cutting processes. This machine is engineered for large-format material processing, accommodating various extensive materials. With powerful laser options like 10000w and 12000w, it efficiently cuts a wide range of metal materials. It is particularly suitable for the rapid cutting of stainless steel, carbon steel, galvanized plates, electrolytic plates, brass plates, aluminum plates, manganese steel, various alloy plates, rare metals, and more.

Open Type Large Laser Cutting Machine High Power 12000w 10000w Laser Cutting Machine for Sheet Metal Laser Cutting Video

Open Type Large Laser Cutting Machine High Power 12000w 10000w Laser Cutting Machine for Sheet Metal Laser Cutting Advantages

High-Strength Machine Bed

Built with a high rigidity machine bed and a specialized high-temperature CNC furnace annealing process, ensuring long-lasting stable performance.

Exceptional Laser Performance

Featuring an imported original encapsulated fiber laser, it delivers excellent beam quality, stable performance, and has a lifespan exceeding 100,000 hours. It’s maintenance-free with no need for optical path adjustments.

Superior Conversion Efficiency

The fiber laser boasts an electro-optical conversion efficiency of up to 30%, significantly cutting down power consumption and operational costs.

Fast and Economical Cutting

With its rapid cutting speeds, this machine ensures extremely low operating costs and offers a swift return on investment.

Enhanced Motor System

Equipped with an open single pallet system and dual synchronous motor drive, providing improved performance.

High-Power Laser Source

Integrated with a 12kw high-power fiber laser generator, offering high-quality processing and efficiency.

Easy to Operate

Designed for straightforward operation, ensuring user-friendliness.

Minimal Maintenance

Ensures low energy consumption and minimal maintenance requirements.

DXTECH Service

We warmly welcome domestic and overseas customers to visit our factories and offices and talk about business in person. We now have one workshop with an area of 45,000㎡ in Jinan and one factory with an area of 30,000㎡ under construction in Taian, Shandong Province.

Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

DXTECH Quality Assurance

2 Years free warranty

- This warranty only covers normal use of the laser machine

- This warranty does not cover any third party software or virus related issues not purchased from DXTECH

- We continue to provide lifetime free technical support to original customers. However, the warranty is not transferable.

Complete After-sales Service

- Your salesperson and factory technicians will together take care of all your after-sales issues from the moment you received the laser machine.

- We provide free online training and techinical support. Besides, we can also go to your place to settle down the installation, debugging, training, and using matters.

Customer feedback

Components of Fiber Laser Cutting machine

Intelligent focusing laser head

1) Cooling: both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

2) Chasing aperture: through the 35 mm aperture, the interference of stray light is effectively reduced.

3) Autofocus: without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel plate welding bed

Adopting high-quality carbon plate steel welding bed, it is more stable and durable than normal tube welding bed. The high-strength machine tool adopts 600 ℃ stress relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Aviation aluminum beam

1) It has the characteristics of corrosion resistance, light weight, and high rigidity, which ensures high-speed movement during laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., ensuring higher cutting accuracy.

FAQ

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled plate, copper, silver, gold, titanium and other metal plates and pipes.

Fiber laser, stepper motor, servo motor, bed, laser head, water chiller, control system, etc.

Protective lenses, nozzles, ceramic rings.

The shape of the laser beam, the width of the slit, the accuracy of the table, and the material of the work piece.

Reviews

There are no reviews yet.